Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Behind every motorcycle’s performance and style are moulds that shape its parts. From fairings and fenders to engine housings, this article explains what motorcycle parts moulds are, the main types used, and the complete process from design to finished components.

A motorcycle parts mold is a specialized tool used for mass production of motorcycle parts. It uses specific processes (such as injection molding, die casting, stamping, and rubber molding) to transform raw materials (plastic, metal, rubber, etc.) into precisely structured and uniformly shaped motorcycle parts.

In other words, the mold is the "mother body" of the part, determining the appearance, dimensions, tolerances, and surface quality of the motorcycle parts. Without molds, efficient, large-scale manufacturing of modern motorcycles would be nearly impossible.

Injection Molds

Used for plastic parts such as fairings, fenders, headlights, instrument housings, and handlebars.

Common materials include ABS, PP, PC, and nylon.

Die Casting Molds

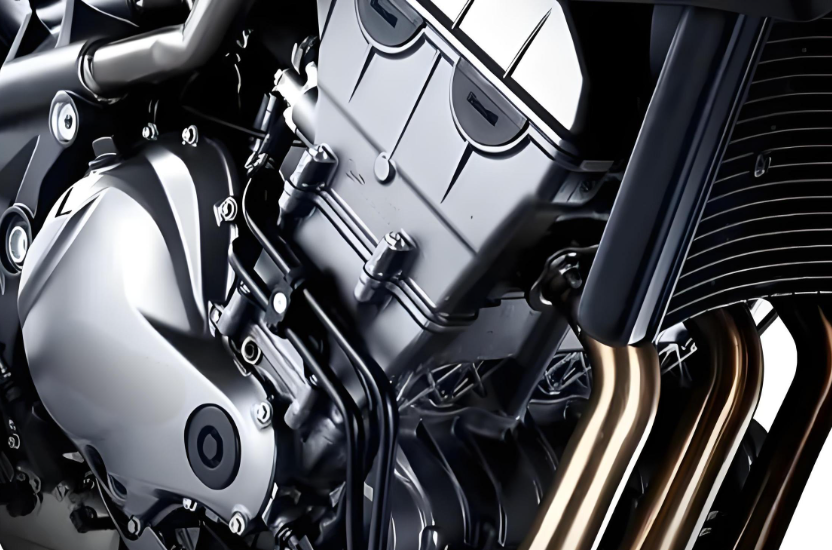

Used for metal parts such as engine housings, footrest brackets, and aluminum alloy covers.

Molds are formed by injecting molten metal under high pressure.

Stamping Dies

Used for sheet metal parts, such as fuel tank housings and frame covers.

They use the pressure of a punch to press steel sheets into shape.

Rubber/Silicone Molds

Used for rubber accessories such as foot-pegs, dust boots, and seals.

Composite Molds

Carbon fiber and fiberglass parts used on high-end motorcycles, such as lightweight fairings.

The first step is design. Engineers create a 3D model in CAD/CAE based on the vehicle's functional and aesthetic requirements. They evaluate factors such as strength, assembly, heat dissipation, and fluid flow, and select a material option, such as ABS, PP, PC, nylon, aluminum alloy, magnesium alloy, or rubber or carbon fiber. This stage also considers draft angles, wall thickness, rib placement, gate location, and subsequent surface treatment, laying the foundation for mass production manufacturability (DFM).

Once the part model is in place, mold making begins. Based on the molding process (injection molding, die casting, stamping, rubber compression/injection), the mold structure is designed, and steel is selected and processed. This process typically includes CNC milling, electrical discharge machining (EDM), mirror polishing, assembly, and mold trials. Mold accuracy, as well as venting, cooling, and gate/runner layout, determine the part's appearance, dimensional stability, and yield. The mold is essentially the "mother body" of the part.

The materials must be pre-treated according to process requirements. Plastic pellets (ABS, PP, PC, PA) typically require drying to remove moisture and prevent silver streaks and bubbles. Metal raw materials (aluminum, magnesium, steel) must be heated to the molten range, maintaining temperature and cleanliness. Rubber/silicone is mixed, metered, and pressed into preforms to ensure consistent flow and solidification.

Entering the mass production molding stage. Injection molding involves injecting molten plastic into the mold under high pressure, then ejecting it from the mold after cooling. This is suitable for exterior and thin-walled parts. Die casting involves pressing molten aluminum/magnesium into a mold at high speed, rapidly solidifying it to produce high-strength, complex metal parts. Stamping uses sheet metal as the raw material, and the punch press and die combine to form the blank, bend, and draw it. Rubber compression/injection molding involves filling the mold cavity with preforms and solidifying them under high temperature and high pressure. This is suitable for elastomeric parts such as pedal rubbers and seals.

After molding, the part is smoothly ejected using ejectors/ejectors to prevent deformation and strain. Subsequently, in-mold or out-mold cooling, either natural cooling or forced air/water cooling, is performed to stabilize dimensions and shape and reduce internal stress. This is particularly critical for transparent or high-gloss parts, as the temperature and cooling rate directly impact appearance and optical performance.

Flash and gate areas are trimmed, and grinding and chamfering are performed as necessary. Surface treatments such as painting, electroplating, anodizing, silk-screen/pad printing, laser engraving, or polishing are applied based on part positioning and appearance requirements. Metal parts may also undergo heat treatment or surface hardening to enhance wear resistance and fatigue life.

Dimensional inspections are conducted using calipers, gauges, or coordinate measuring machines (CMMs). Appearance inspections include scratches, sink marks, bubbles, silver streaks, weld marks, and color variations. Performance testing includes impact, heat resistance, weathering, fatigue, and assembly reliability testing. Process capability (Cpk), first article approval (FAI), or PPAP documentation is established as necessary to ensure stable mass production.

Qualified parts are stored and delivered to the final assembly line as planned. Assemblers install them in their designated locations, such as fairings, fenders, instrument panels, engine housings, and chain guards. After installation, functionality, clearances, and appearance are reconfirmed to ensure riding safety and consistent vehicle quality.

This is the complete process from mold to finished part: design → mold making → material preparation → molding → demolding and cooling → post-processing → testing → assembly. Each step is closely linked, and the mold plays a crucial role, determining efficiency, quality, and cost.

In the production of motorcycle parts, molds are known as the "mother of industry." They are more than just a forming tool; they are central to determining the precision, quality, and production efficiency of the parts. The following aspects highlight the importance of molds:

Molds are like the "mother" of a part, directly determining the size, geometry, and details of motorcycle parts.

For exterior parts such as fairings, fenders, and tailgates, molds ensure smooth curves and a smooth surface. For structural parts such as engine cases, brackets, and fuel tank housings, molds ensure the intricate details of internal structures and precise assembly positions.

Without high-precision molds, it's impossible to mass-produce consistent parts, let alone meet the assembly requirements of the entire vehicle.

Motorcycle production is typically large-scale, requiring thousands of parts to be consistent. Molds ensure that every part maintains the same specifications and performance from the first to the last. Consistency facilitates smooth assembly and prevents part incompatibilities. High-efficiency molding methods (injection molding, die-casting, and stamping) all rely on molds to quickly reproduce parts.

Molds enable single-shot molding, eliminating numerous cutting and welding steps.

Injection molds: Molding a plastic part in seconds.

Die-casting molds: Producing complex aluminum alloy components with a single pour.

Stamping molds: Producing dozens of presses per minute.

This high efficiency significantly reduces unit cost, making motorcycle parts more cost-effective while ensuring quality.

Molds not only shape the part but also influence its mechanical properties and durability.

Cooling system design: Influences the crystallinity and strength of the plastic part.

Gating and runner layout: Determines whether the part will experience shrinkage, bubbles, or weld marks.

Mold steel and surface treatment: Impact the wear resistance and finish of the part surface.

Therefore, high-quality molds are a prerequisite for producing high-performance parts.

With the increasing demand for personalization and lightweighting in the motorcycle market, mold design has become a key tool for innovation.

Two-shot injection molds: Create a soft-hard combination of grips and buttons.

Composite molds: Support the molding of carbon fiber fairings, increasing strength while reducing weight.

Custom molds: Enable owners or tuners to achieve unique exterior designs.

Mold precision and lifespan directly determine production line efficiency and yield. High-quality molds can withstand hundreds of thousands or even millions of runs without fail. Low-quality molds require frequent repairs, resulting in downtime, rework, and increased costs.

Therefore, mold manufacturing quality is often a key indicator of a motorcycle manufacturer's technical capabilities.

In summary:

In motorcycle parts manufacturing, molds serve as both a "styling tool," a "quality guarantor," and an "efficiency accelerator." They transform designs into reality, enabling mass production and consistent parts, and driving the entire industry toward high performance, low cost, and customization.

At GUANGCHAO, we specialize in designing and manufacturing high-precision motorcycle parts moulds that turn ideas into reality. From fairings and fenders to dashboards and custom accessories, our mould solutions guarantee consistency, durability, and cost-effective production. Whether you need OEM-grade tools or customized designs for aftermarket innovation, our team delivers reliable moulds backed by years of expertise and advanced technology.

Explore our full range of Motorcycle Parts Mould solutions to discuss your project today. Together, we can build moulds that power the next generation of motorcycles.

1. What is a motorcycle parts mould?

A motorcycle parts mould is a specialized tool used to mass-produce components such as fairings, fenders, and engine housings. It shapes raw materials like plastic, metal, or rubber into precise and consistent parts.

2. Which manufacturing processes use motorcycle parts moulds?

Common processes include plastic injection molding, metal die casting, sheet metal stamping, and rubber/silicone molding. Each process is chosen based on the material and the type of part.

3. Why are moulds important in motorcycle manufacturing?

Moulds ensure accuracy, repeatability, and efficiency. They determine the final shape and quality of each part, making large-scale production cost-effective and reliable.

4. What materials are commonly used in motorcycle parts moulding?

Plastics like ABS, PP, PC, and nylon are used for body panels and housings; aluminum and magnesium alloys for engine and structural parts; and rubber or silicone for seals and grips.

5. Can motorcycle parts moulds be customized?

Yes. Custom moulds allow for unique designs, textures, and finishes, supporting both OEM production and aftermarket customization to meet different performance and aesthetic needs.