Views: 0 Author: Site Editor Publish Time: 2025-05-23 Origin: Site

Blow moulding is a pivotal manufacturing process used extensively in the production of hollow plastic parts. This technique has revolutionized the way we create everyday items, from simple bottles to complex industrial components. As technology advances, the applications of blow moulding continue to expand, offering innovative solutions across various industries. Understanding the intricacies of blow moulding provides valuable insights into its role in modern manufacturing and the potential it holds for future developments.

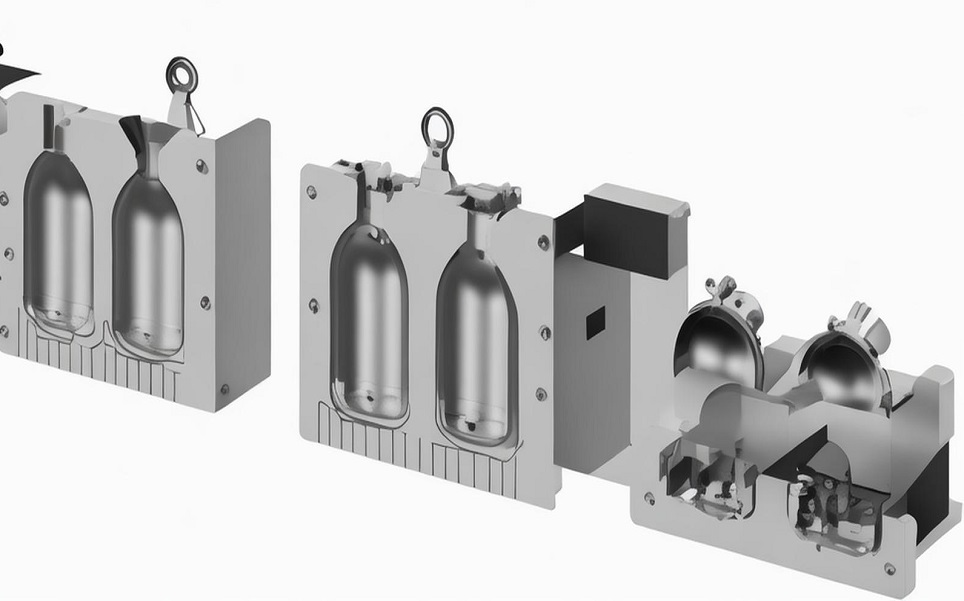

At its core, blow moulding involves inflating a heated plastic tube until it fills a mould and forms the desired shape. This process is particularly suited for creating hollow objects with uniform wall thickness. There are several types of blow moulding methods, including extrusion blow moulding, injection blow moulding, and injection stretch blow moulding. Each method offers unique advantages, making it essential to select the appropriate technique based on the application requirements.

Extrusion blow moulding is commonly used for producing items like bottles, containers, and automotive components. The process begins with melting plastic and forming it into a parison—a tube-like piece of plastic with a hole in one end through which compressed air can pass. The parison is then clamped into a mould, and air is blown into it, expanding the plastic and pressing it against the mould walls. This method is efficient for high-volume production of medium to large-sized products.

Injection blow moulding combines the principles of injection moulding and blow moulding. It is ideal for producing small, precise hollow objects such as medicine bottles and cosmetic containers. In this process, the plastic is first injected into a mould to form a preform, which is then transferred to a blow moulding station. Here, the preform is heated and air is injected, expanding it to the final shape. This method offers high accuracy and consistency, making it suitable for products requiring tight dimensional tolerances.

This technique is commonly used for making PET bottles, such as those used for beverages. Injection stretch blow moulding enhances material properties by stretching the preform both axially and radially during the blowing process. This orientation of the polymer chains improves the strength and clarity of the final product. The method is divided into one-stage and two-stage processes, offering flexibility in production based on specific needs.

Blow moulding has a vast array of applications due to its versatility in producing complex shapes with uniform wall thickness. Its primary use is in the packaging industry, but its reach extends far beyond.

The packaging industry heavily relies on blow moulding for producing containers and bottles. Products like Medicine Bottles mould are essential for pharmaceutical packaging, ensuring safety and compliance with health standards. The ability to produce containers of various sizes and shapes makes blow moulding indispensable for packaging liquids, powders, and granular products.

In the automotive sector, blow moulding is used to manufacture complex parts like fuel tanks, ductwork, and reservoirs. The process allows for the creation of lightweight yet durable components that contribute to overall vehicle efficiency. Advanced materials and blow moulding techniques enable manufacturers to meet stringent performance and safety requirements.

Blow moulding is pivotal in producing industrial containers and pallets. For instance, Blowing Pallets mould are essential for creating durable, lightweight pallets used in shipping and storage. These pallets offer advantages over traditional wooden pallets, including resistance to moisture and pests, and they are recyclable, aligning with sustainability goals.

From toys to Commodity items, blow moulding enables the mass production of diverse consumer goods. Its ability to produce items with complex shapes and hollow structures makes it ideal for products like water bottles, sports equipment, and even furniture components. The efficiency of the process helps keep production costs low while maintaining high quality.

The selection of materials is crucial in blow moulding, as it affects the properties and performance of the final product. Commonly used plastics include:

PE is the most widely used plastic in blow moulding due to its versatility and excellent mechanical properties. High-density polyethylene (HDPE) is used for rigid products like containers and bottles, while low-density polyethylene (LDPE) is utilized for more flexible items.

PET is known for its strength, transparency, and gas barrier properties, making it ideal for beverage bottles and food packaging. Its recyclability also contributes to its popularity, aligning with environmental sustainability efforts.

PP offers a balance of strength, chemical resistance, and high-temperature tolerance. It's used in applications requiring durability and stability, such as automotive parts and industrial containers.

Technological innovations have propelled blow moulding into new realms of possibility. Improved automation, precision control systems, and enhanced mould designs have increased efficiency and product quality. Computer-aided design (CAD) and simulation software allow for the optimization of moulds and processes before physical production, reducing development time and costs.

The industry is increasingly focusing on sustainability. Recycled materials are being incorporated into blow moulding processes, and biodegradable plastics are under development. Manufacturers are optimizing designs to reduce material usage without compromising product integrity, contributing to environmental conservation.

Expertise in blow moulding is essential for producing high-quality products. A reputable blow moulding manufacturer brings technical knowledge, advanced equipment, and innovative solutions to the table. Collaboration with manufacturers can lead to custom designs that meet specific requirements, ensuring functionality and cost-effectiveness.

Maintaining rigorous quality control is vital in blow moulding. Manufacturers adhere to industry standards and certifications to ensure products meet safety and performance criteria. Non-destructive testing, material analysis, and process monitoring are integral parts of quality assurance, minimizing defects and enhancing product reliability.

Despite its advantages, blow moulding presents challenges such as material shrinkage, wall thickness distribution, and surface imperfections. Advances in technology and process control help mitigate these issues. Simulation software can predict potential problems, allowing engineers to make necessary adjustments before production.

The future of blow moulding is promising, with trends pointing towards increased automation, the use of eco-friendly materials, and integration with Industry 4.0 technologies. Smart manufacturing practices enable real-time monitoring and data analysis, improving efficiency and reducing waste.

Several industries have successfully implemented blow moulding to enhance their products. For example, the automotive industry has reduced vehicle weight by using blow-moulded plastic components, improving fuel efficiency. In the packaging sector, companies have developed innovative bottle designs that use less plastic while maintaining strength, reducing environmental impact.

Industry experts emphasize the importance of continuous innovation in blow moulding. By embracing new materials and technologies, manufacturers can meet evolving market demands. Collaboration between material scientists, engineers, and designers is key to developing products that are both functional and sustainable.

Businesses looking to leverage blow moulding should consider the following:

Partner with experienced manufacturers to benefit from technical expertise.

Invest in design and simulation to optimize product and process before production.

Stay informed about material innovations to improve product performance and sustainability.

Implement quality control measures to ensure consistency and compliance with standards.

Blow moulding is a versatile and essential process in modern manufacturing with applications spanning multiple industries. From creating everyday Commodity items to complex industrial components, its impact is significant and far-reaching. As technology advances, the capabilities of blow moulding will continue to grow, offering innovative solutions that meet the demands of a changing world. By understanding the process and engaging with expert blow moulding manufacturers, businesses can harness the full potential of this technology to produce high-quality, sustainable products.