Views: 0 Author: Site Editor Publish Time: 2025-05-30 Origin: Site

The production of PET (Polyethylene Terephthalate) bottles is a critical aspect of the packaging industry, serving a wide range of sectors from beverages to pharmaceuticals. Central to this manufacturing process is the PET bottle mould, a tool that shapes molten PET into the desired bottle form. Understanding the materials used in these moulds is essential for manufacturers aiming to produce high-quality bottles efficiently and cost-effectively. This article delves into the various materials employed in crafting PET bottle moulds, their properties, advantages, and how they impact the overall production process. By exploring these materials, manufacturers can make informed decisions when selecting a pet bottle Mould supplier that meets their specific needs.

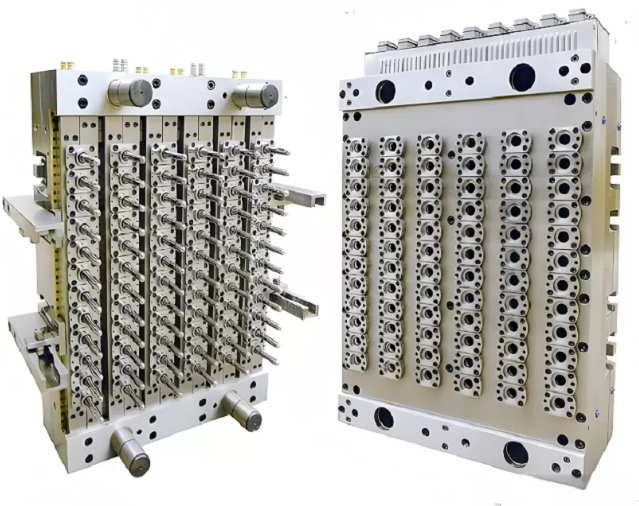

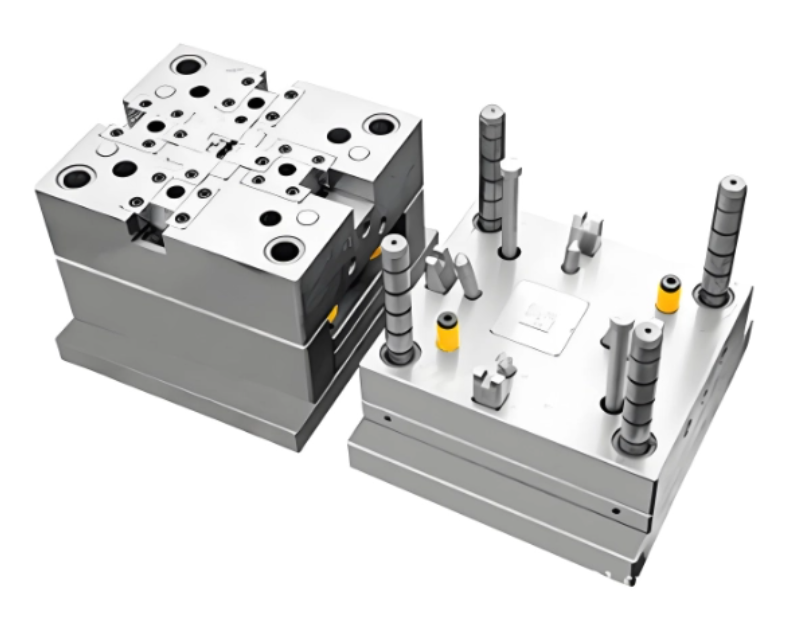

PET bottle moulds are precision-engineered tools used in the blow molding process to produce PET bottles of various shapes and sizes. The mould's design and material significantly influence the quality of the bottles produced, affecting factors such as clarity, strength, and production efficiency. Moulds must withstand high temperatures and pressures while maintaining precise dimensions over repeated use cycles.

Selecting the right material for PET bottle moulds is crucial for longevity and performance. The commonly used materials include various grades of steel and aluminum alloys, each offering distinct properties that cater to different production requirements.

P20 steel is a widely used material in mould making due to its excellent machinability and uniform hardness. It is pre-hardened to approximately 30 HRC, providing good toughness and strength. P20 steel offers a balanced combination of wear resistance and durability, making it suitable for medium to large volume production of PET bottles.

718H steel is an upgraded version of P20 steel, offering higher hardness levels of around 33-38 HRC. This higher hardness translates to improved wear resistance, making it ideal for higher volume production runs. The enhanced mechanical properties of 718H steel contribute to longer mould life and consistent bottle quality.

Stainless steel moulds are preferred in applications where corrosion resistance is paramount. Grades like S136 and 420 stainless steel provide excellent resistance to rust and chemical attack, which is essential when moulds are exposed to moisture or corrosive substances. Additionally, stainless steel can achieve a high polish, resulting in superior surface finishes on PET bottles.

Aluminum alloys are used for moulds requiring rapid heat dissipation. Their excellent thermal conductivity allows for quicker cooling times, increasing production efficiency. However, aluminum moulds are less durable than steel moulds and are typically used for short production runs or prototype development.

The choice of material for a PET bottle mould hinges on several key properties that affect performance and cost. Understanding these properties helps manufacturers select materials that align with their production goals.

Materials with higher hardness levels offer better wear resistance, essential for moulds subjected to repetitive stress and high production volumes. Steel grades like 718H are favored for their ability to maintain structural integrity over prolonged use.

Efficient heat transfer is vital for reducing cycle times in PET bottle production. Materials with high thermal conductivity, such as aluminum alloys, enable faster cooling of the mould and the formed bottle, increasing throughput.

Corrosion can compromise mould integrity and bottle quality. Stainless steel materials offer superior corrosion resistance, extending the mould's lifespan and ensuring consistent product quality, especially in humid or chemically aggressive environments.

Materials that are easier to machine and polish can reduce manufacturing costs and lead times. P20 and 718H steels balance machinability with durability, allowing for precise mould fabrication and high-quality surface finishes.

The mould-making industry continually evolves, with research focusing on developing new materials and treatments to enhance mould performance. Recent advancements include the use of beryllium copper alloys and specialized coatings.

Beryllium copper alloys combine the strength of steel with the thermal conductivity of copper. These materials help in achieving uniform temperature distribution within the mould, reducing cycle times, and improving bottle quality. Their use is particularly beneficial in complex mould designs where heat dissipation is critical.

Advanced surface treatments like nitriding and PVD (Physical Vapor Deposition) coatings enhance the surface hardness and wear resistance of mould materials. These treatments can significantly extend the mould's service life and maintain the integrity of the bottle surface finish over extended production runs.

Selecting the appropriate mould material involves balancing multiple factors, including production volume, bottle design complexity, and budget constraints. Collaborating with an experienced pet bottle Mould solutions provider can aid in navigating these considerations.

High-volume production requires materials that can withstand prolonged use without significant wear. Investing in higher-grade steels or treated surfaces may incur higher initial costs but offer savings over time through reduced maintenance and replacement expenses.

Intricate bottle designs may necessitate materials that provide excellent machinability and the ability to achieve fine details. Materials like aluminum alloys or high-quality steels enable precise mould fabrication to meet complex design specifications.

While high-end materials offer superior performance, budget limitations may require compromises. Understanding the trade-offs between material costs and mould longevity is essential. In some cases, opting for cost-effective materials with adequate properties for the intended production scale is a practical approach.

Examining real-world applications provides valuable insights into the impact of material selection on PET bottle production.

A major beverage company sought to increase its PET bottle production efficiency. By switching from standard P20 steel moulds to moulds made with beryllium copper alloys, the company reduced cooling times by 30%. This change led to a significant increase in output and a quick return on investment despite the higher initial mould cost.

In pharmaceutical packaging, precision and cleanliness are paramount. A pharmaceutical company opted for stainless steel moulds with PVD coatings to minimize contamination risks and ensure high-quality surface finishes. The corrosion-resistant properties of stainless steel were crucial in maintaining sterility and product integrity.

Manufacturers can optimize their production processes by adhering to best practices when selecting mould materials.

Engaging with material scientists and experienced mould makers can provide insights into the latest material technologies and how they apply to specific production needs. Experts can recommend materials that balance performance and cost effectively.

Beyond initial material costs, manufacturers should consider the total cost of ownership, including maintenance, downtime, and replacement expenses. Materials that offer longer mould life and reduce cycle times can lead to significant cost savings over the mould's operational lifetime.

No single material suits all applications. Customizing material choices based on specific production parameters ensures optimal performance. This customization may involve combining materials, such as using steel mould bases with aluminum inserts, to leverage the advantages of each material where they are most needed.

Emerging technologies are reshaping the landscape of mould material selection, introducing new possibilities for manufacturers.

Additive manufacturing, or 3D printing, enables the creation of complex mould geometries that were previously unattainable. Materials used in additive processes, such as maraging steel, offer high strength and can incorporate conformal cooling channels, enhancing thermal management within the mould.

Composite materials, combining metals with ceramics or polymers, are being explored for mould applications. These materials aim to provide a balance of high strength, wear resistance, and thermal conductivity, potentially revolutionizing mould performance.

Sustainability is an increasingly important factor in manufacturing. Choosing mould materials that align with environmental objectives can contribute to a company's overall sustainability goals.

Materials like steel and aluminum are recyclable, allowing for the repurposing of mould components at the end of their service life. This recyclability reduces waste and the environmental impact associated with raw material extraction.

Materials that enhance thermal conductivity can reduce energy consumption by decreasing cycle times and the energy required for heating and cooling. This efficiency contributes to lower operational costs and a smaller carbon footprint.

Partnering with a reputable pet bottle Mould supplier is critical for accessing high-quality materials and expert guidance. A supplier with a proven track record can provide customized solutions, technical support, and after-sales service, ensuring the moulds meet the production demands and quality standards.

The material of a PET bottle mould profoundly affects the efficiency, cost, and quality of bottle production. By understanding the properties and applications of various mould materials, manufacturers can make informed decisions that enhance their production capabilities. Advances in material technology and a focus on sustainability offer new opportunities for optimization. Collaborating with experienced suppliers and experts further ensures that the selected mould materials align with specific production needs and strategic objectives. As the packaging industry continues to evolve, staying abreast of material innovations will be essential for maintaining competitiveness and meeting the growing demands of the market.