Views: 0 Author: Site Editor Publish Time: 2025-06-06 Origin: Site

Plastic injection molding stands as a cornerstone of modern manufacturing, enabling the mass production of complex plastic components with unparalleled precision and efficiency. The process hinges on the use of molds, which are intricately designed to shape molten plastic into the desired forms. Selecting the appropriate type of mold is critical for ensuring product quality, optimizing production costs, and achieving manufacturing efficiency. This comprehensive examination explores the various types of molds utilized in plastic injection molding, delving into their unique characteristics, applications, and the factors influencing their selection.

While injection molding is a dominant method for producing solid plastic parts, other processes such as Plastic Blowing Mould techniques are essential for creating hollow products like bottles and containers. Understanding the nuances between these methods highlights the versatility of plastic molding technologies in addressing diverse manufacturing needs.

At its core, plastic injection molding involves melting plastic pellets and injecting the molten material into a mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens to release the finished part. This process is highly efficient for producing large volumes of parts with consistent quality and is widely used across industries such as automotive, medical devices, consumer goods, and electronics.

The success of injection molding relies heavily on the mold's design and construction. Molds must withstand the mechanical stresses of repeated use, maintain tight tolerances, and facilitate efficient heat transfer for rapid cooling. As such, molds are typically crafted from durable metals like steel or aluminum and may incorporate complex mechanisms for features like undercuts or threaded components.

The diversity of Plastic Blowing Molding Parts necessitates a variety of mold types, each tailored to specific production requirements and product designs. The following sections detail the primary types of molds employed in plastic injection molding.

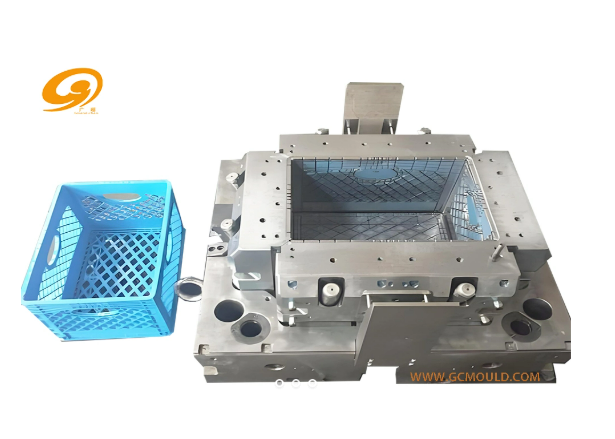

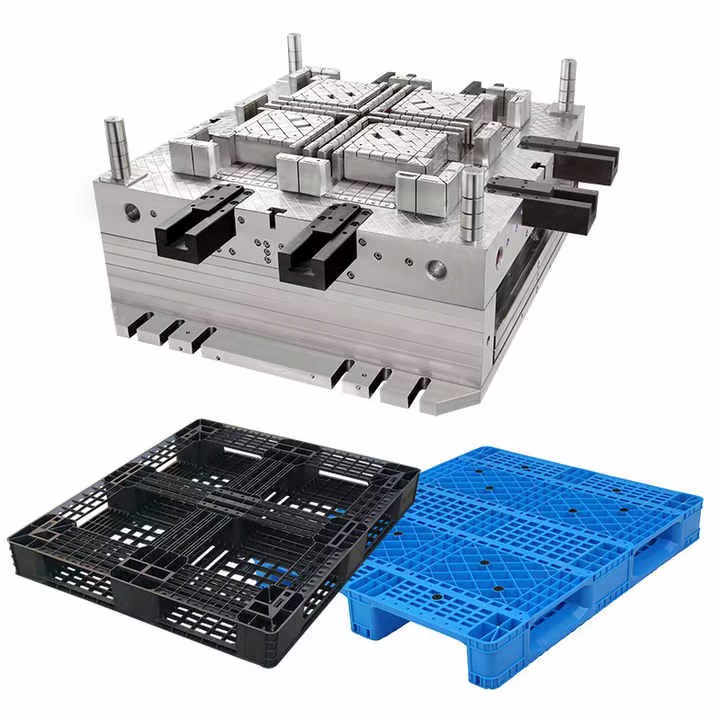

Single-cavity molds produce one part per cycle and are straightforward in design. They are ideal for low to medium production volumes and are cost-effective for parts that are large, complex, or require high precision. The simplicity of single-cavity molds allows for easier maintenance and shorter lead times in mold fabrication.

Multi-cavity molds feature multiple cavities of the same part, enabling the production of several identical parts per cycle. This design significantly enhances production efficiency and reduces unit costs in high-volume manufacturing. However, multi-cavity molds require more complex design considerations to ensure uniform filling, cooling, and part quality across all cavities.

Family molds contain cavities for different parts within the same mold. This approach is beneficial when producing sets of components that will be assembled together, as it ensures all parts are molded simultaneously under identical conditions. While cost-effective, family molds demand meticulous design to manage varying part sizes and shapes, ensuring consistent quality across all components.

Insert molding involves placing a pre-formed component, often metal, into the mold cavity before injecting plastic around it. This process integrates multiple materials into a single part, enhancing functionality without the need for secondary assembly. Insert molds are widely used in producing items like threaded inserts, electrical components, and parts requiring reinforcement.

Overmolding is a specialized form of insert molding where an additional layer of plastic is molded over an existing part, which may be plastic or another material. This technique is used to create multi-material components, add ergonomic features like soft grips, or encapsulate electronics. Overmolding requires precise temperature and material compatibility management to ensure strong bonding between layers.

Two-shot, or multi-shot molding, utilizes molds designed to inject two different materials or colors sequentially into a single mold during one cycle. This method produces parts with complex designs and multiple materials without additional assembly steps. Two-shot molds are intricate and require advanced machinery capable of handling multiple injection units.

Hot runner molds incorporate heated components within the mold to keep the plastic in the runner system molten. This design minimizes material waste by eliminating the need for runners to solidify with each cycle, enhancing efficiency and reducing costs. While more expensive and complex, hot runner systems are advantageous for high-volume production and parts requiring fast cycle times.

In contrast, cold runner molds allow the runner material to cool and solidify along with the part. The runner must be removed and often recycled or discarded after each cycle. Cold runner systems are simpler and less costly than hot runners but may result in increased material waste and longer cycle times due to additional processing steps.

Choosing the appropriate mold type involves considering various factors related to the part design, production volume, material selection, and cost constraints. Key considerations include:

1. Part Complexity: Intricate designs with complex geometries may require specialized molds like insert or overmolds to achieve the desired features.

2. Production Volume: High-volume production often justifies the investment in multi-cavity or hot runner molds to enhance efficiency and reduce per-unit costs.

3. Material Characteristics: The type of plastic material, its flow properties, and heat sensitivities can influence mold design choices, particularly regarding runner systems and cooling mechanisms.

4. Desired Surface Finish: Molds may require specific surface treatments or textures to achieve the intended aesthetic or functional surface qualities of the part.

5. Budget Constraints: Initial mold fabrication costs vary widely. Single-cavity and cold runner molds are less expensive upfront, whereas multi-cavity and hot runner molds require higher initial investment but offer long-term cost savings in high-volume production.

The construction material of a mold significantly impacts its durability, thermal conductivity, and cost. Common materials include:

1. Tool Steel: Highly durable and capable of withstanding high temperatures and pressures, tool steel is ideal for high-volume production and parts requiring tight tolerances.

2. Stainless Steel: Offers excellent corrosion resistance and is suitable for medical or food-grade applications where mold hygiene is critical.

3. Aluminum: Lightweight and with superior thermal conductivity, aluminum molds allow faster cooling cycles. They are cost-effective for prototyping and low-volume production but less durable than steel options.

4. Beryllium Copper Alloys: Used in areas of the mold requiring enhanced heat dissipation, beryllium copper inserts help reduce cycle times and improve part quality.

Technological innovations continue to reshape mold design and manufacturing, leading to improved efficiency, precision, and flexibility in plastic injection molding.

The integration of CAD/CAM systems allows for sophisticated mold designs with complex geometries and precise tolerances. Advanced simulation tools enable the prediction and optimization of mold flow, cooling, and potential defects before the mold is fabricated.

Additive manufacturing is increasingly used to produce molds or mold components, particularly for prototyping or low-volume production. 3D printing enables rapid iteration of mold designs, reduces lead times, and allows for complex internal features like conformal cooling channels.

Traditional straight-line cooling channels are being replaced by conformal cooling systems that follow the contours of the mold cavity. This advancement improves heat transfer efficiency, reduces cycle times, and enhances part quality by minimizing thermal disparities.

The development of new materials and surface coatings extends mold life and performance. For instance, nickel or titanium nitride coatings reduce wear and improve demolding. High-performance alloys enhance thermal conductivity and resistance to corrosion or abrasion.

A leading manufacturer of automotive components sought to optimize the production of a complex plastic part used in engine assemblies. Initially utilizing a single-cavity cold runner mold, the company faced limitations in meeting demand due to long cycle times and material waste from runners. By investing in a multi-cavity hot runner mold with conformal cooling channels, the manufacturer achieved a 50% reduction in cycle time and significant material savings. The higher upfront mold cost was offset by increased production efficiency and reduced per-unit costs, demonstrating the strategic value of advanced mold technologies in high-volume manufacturing.

The choice of mold in plastic injection molding is a critical decision that influences product quality, manufacturing efficiency, and overall production cost. Understanding the various types of molds and the factors that guide their selection empowers manufacturers to make informed decisions tailored to their specific needs. Advancements in mold design and technology continue to expand the possibilities in plastic manufacturing, enabling the production of increasingly complex and high-performing components. Whether opting for standard molds or exploring innovative solutions, the strategic emphasis on mold selection remains integral to achieving excellence in injection molding processes.

Collaborating with a reputable Blowing Mould Manufacturer or injection mold specialist ensures access to the latest technologies and expertise, further enhancing the success of manufacturing endeavors.