Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

3D printing is changing the way we think about manufacturing. It allows for complex designs, rapid prototyping, and customized solutions. But how does it work?

In this article, we will explore what 3D printing is, its history, and how it works. You’ll also learn about different types of 3D printing technologies and their practical applications in various industries.

3D printing, also known as additive manufacturing, is a revolutionary process that creates physical objects from digital files. Unlike traditional manufacturing methods, such as subtractive or formative processes, 3D printing builds objects layer by layer. This additive nature allows for more complex geometries, higher customization, and reduced material waste.

Traditional manufacturing, like milling or injection molding, starts with a solid block or mold and removes material to create the final product. In contrast, 3D printing uses a variety of materials—plastics, metals, resins—and gradually forms the object, often with minimal waste. This method has opened up new possibilities for industries that require intricate designs, such as aerospace, healthcare, and automotive.

The process of 3D printing begins with a digital 3D model, often created using computer-aided design (CAD) software. This model is then converted into a set of instructions through slicing software, which divides the model into thin layers. The 3D printer follows these instructions to deposit material layer by layer until the object is fully formed.

Different 3D printing technologies use different materials and methods for layer deposition. For instance, Fused Deposition Modeling (FDM) melts plastic filament, which is extruded through a heated nozzle to build each layer. Stereolithography (SLA), on the other hand, uses ultraviolet light to cure resin in layers. The type of material and technology used depends on the desired properties of the final product, such as strength, flexibility, or surface finish.

The history of 3D printing dates back to the early 1980s. The first key invention was by Charles Hull, who developed Stereolithography (SLA) in 1984, a method that uses ultraviolet light to solidify liquid resin layer by layer. Hull's invention laid the foundation for the first commercial 3D printing systems and gave birth to 3D Systems, the company he founded to bring this technology to market.

In 1987, Hull and his company produced the first 3D printer, which used SLA to create prototypes directly from digital files. This breakthrough allowed designers to visualize and test their ideas more efficiently than ever before. Around the same time, other technologies like Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) were being developed, expanding the potential uses of 3D printing.

By the early 2000s, 3D printing technology became more affordable and accessible to the general public. The open-source RepRap project, launched in 2005, aimed to create self-replicating 3D printers. This led to a surge in interest from hobbyists and small businesses. In 2009, MakerBot released a low-cost desktop 3D printer, which helped democratize the technology even further.

As patents on early 3D printing technologies expired, more companies entered the market, leading to an explosion of innovation. This era also saw the introduction of more affordable and user-friendly 3D printers, making it possible for individuals to experiment and innovate with 3D printing in their homes and workshops.

Vat polymerization technologies, including Stereolithography (SLA), Digital Light Processing (DLP), and Continuous Digital Light Processing (CDLP), use light to cure liquid resin into solid layers. These technologies are known for producing highly detailed prints with smooth finishes, making them ideal for applications such as jewelry, dental models, and medical prototypes.

SLA, the most common form of vat polymerization, uses an ultraviolet laser to harden the resin layer by layer. DLP and CDLP are similar but differ in how they cure the resin—DLP uses a digital projector to flash an entire layer at once, while CDLP utilizes continuous movement of the build platform.

Tip: If your project demands fine detail and smooth surface finishes, SLA or DLP might be the best options.

Powder bed fusion (PBF) is a versatile technology that uses a laser or electron beam to fuse powder particles layer by layer. Technologies like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) are popular in industries requiring strong, functional parts, such as aerospace, automotive, and medical fields.

SLS uses a laser to sinter polymer powders, creating durable and complex parts. DMLS, on the other hand, is used for metal printing and is perfect for producing high-density metal components with intricate geometries. Both methods allow for the creation of parts that do not require additional support structures, which is a major advantage over other 3D printing technologies.

Technology | Materials | Key Features | Ideal Applications |

SLS | Plastic powders | Strong, complex geometries, no supports | Aerospace, Automotive, Prototyping |

DMLS | Metal powders | High-density parts, metal printing | Aerospace, Medical, Engineering |

Tip: For industries that require strong, high-performance parts, PBF technologies like SLS and DMLS are the go-to options.

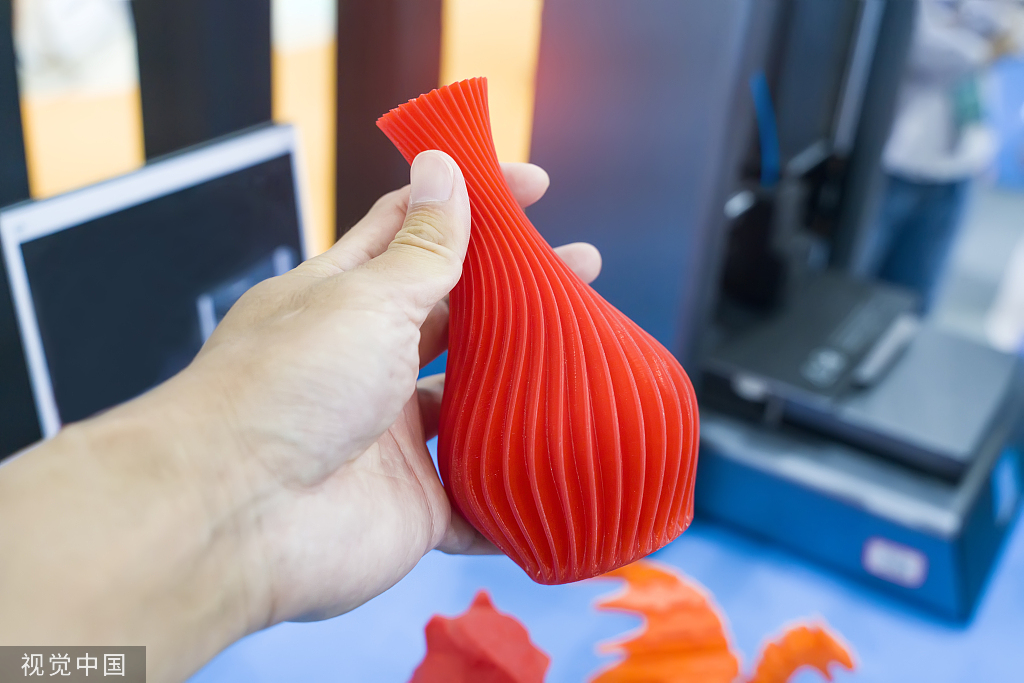

Material extrusion is perhaps the most widely known 3D printing process, with Fused Deposition Modeling (FDM) being the most common technology. FDM works by melting a filament of thermoplastic material, which is then extruded through a nozzle and deposited layer by layer onto the build platform.

While FDM is relatively inexpensive and easy to use, it is best suited for applications where the highest precision or strength is not critical. It is widely used for prototyping, creating simple parts, or in educational settings.

Tip: If you are just starting with 3D printing or working on a tight budget, FDM printers offer an affordable solution for low-complexity projects.

Material jetting is a precision-based 3D printing technology that deposits droplets of material onto the build platform. This process is similar to inkjet printing but uses materials such as photopolymers, metals, or waxes. It offers excellent resolution and smooth finishes, making it ideal for producing detailed models and prototypes.

Material Jetting can be particularly useful in industries like jewelry and consumer goods, where high detail and complex designs are required.

Direct Energy Deposition (DED) uses focused thermal energy, such as lasers or electron beams, to melt material, which is then deposited onto the workpiece. DED is primarily used in metal printing and is favored for large parts or for repairing damaged components in industries like aerospace, defense, and manufacturing.

3D printing has become a game-changer for industries like aerospace, automotive, and manufacturing. The technology enables faster prototyping and the creation of lightweight, complex parts that would be difficult or expensive to produce using traditional methods.

For example, companies like Boeing and Airbus use 3D printing to create lightweight components for their aircraft, reducing fuel costs and improving performance. In automotive manufacturing, companies like Ford and General Motors use 3D printing for rapid prototyping and producing small runs of custom parts.

In the healthcare sector, 3D printing is transforming how medical devices and implants are created. For example, 3D printing is used to make custom prosthetics, hearing aids, and dental implants, ensuring a perfect fit for each patient.

Medical models printed from 3D scans allow surgeons to practice complex procedures before operating on patients, reducing risks and improving outcomes.

3D printing allows companies in the consumer goods and fashion industries to produce custom-designed products on demand. From personalized jewelry to customized footwear, 3D printing offers an unprecedented level of design freedom. Brands like Adidas and Nike are already exploring the possibilities of 3D-printed shoes tailored to individual customers.

3D printing offers many benefits, including:

● Low startup costs: Unlike traditional manufacturing, 3D printing requires minimal setup, making it ideal for low-volume production.

● Design freedom: Complex geometries and customized designs can be easily produced without extra costs.

● Rapid prototyping: 3D printing accelerates the product development cycle, allowing businesses to quickly iterate designs.

Despite its advantages, 3D printing has some drawbacks:

● High production costs for large volumes: While it's cost-effective for small runs, the per-unit cost increases with higher volumes.

● Limited material choices: Compared to traditional methods, 3D printing still has a narrower range of materials, especially for specific industrial applications.

● Post-processing required: Many 3D printed parts require additional finishing steps, such as sanding or curing, to improve appearance and functionality.

When selecting a 3D printing technology, consider the material properties you need, such as strength, flexibility, and heat resistance. For example, if you need durable parts for industrial applications, metal 3D printing technologies like SLS or DMLS are the best choice.

If your project requires intricate details and high accuracy, technologies like SLA or Material Jetting offer superior resolution. For functional parts with complex geometries, PBF technologies may be the best option.

The future of 3D printing looks promising, with ongoing advancements in material science, printing speed, and automation. The integration of artificial intelligence (AI) and the Internet of Things (IoT) is expected to further streamline the 3D printing process, enabling smarter and more efficient manufacturing systems.

3D printing is set to continue reshaping industries like healthcare, aerospace, and consumer goods. In the coming years, we can expect more widespread adoption of 3D printing technologies for mass customization, on-demand manufacturing, and even environmental sustainability.

3D printing offers many advantages, including low startup costs, design freedom, and rapid prototyping. However, it also presents challenges like high production costs for large volumes and material limitations. As 3D printing continues to shape manufacturing, businesses like Taizhou Huangyan Guangchao Mould Co., Ltd. are providing valuable solutions. Their innovative moulding products are enhancing manufacturing flexibility and efficiency, helping businesses stay competitive in a rapidly evolving market.

A: 3D printing allows for faster prototyping, design flexibility, and reduced material waste, making it an essential tool for industries like aerospace, healthcare, and automotive.

A: Key advantages include low setup costs, the ability to create complex designs, and customization. It also speeds up the prototyping process significantly.

A: The costs vary based on the technology and materials used. However, 3D printing can be more cost-effective for small production runs or prototyping than traditional methods.

A: 3D printing is used in various industries for applications like prototyping, creating custom medical implants, and producing lightweight parts for aerospace and automotive.