Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

Rapid growth in the pet preforms market comes from big changes. These changes are sustainability, technology, and new packaging ideas. The market for pet preform moulds is growing fast. There are strong trends in demand and making things faster. Moulds are very important for making good preforms. They help shape preform quality in packaging. The market grows when makers follow trends and rules. Sustainability changes how preforms look and affects the market. New technology helps Mould and preforms work better. Industry leaders watch trends to meet new packaging needs.

Sustainability helps the PET preform Mould market grow. It does this by using eco-friendly materials and energy-saving machines. These machines make less waste and help with recycling.

New technology like automation and CAD design makes Mould better. Digital tools also help make Mould faster. They let companies make custom preform shapes.

Strict rules make companies use recycled materials. They must also follow safety standards. This helps make packaging greener and safer.

More people want food, drinks, medicine, and cosmetics. This makes the market grow, especially in Asia-Pacific and North America.

B2B customization lets buyers pick Mould designs and features. This helps them save money and follow local rules. They also get better help from suppliers.

Sustainability changes the pet preform Mould market in many ways. Makers now use machines that save energy and make less pollution. These machines help lower carbon footprints and support green manufacturing. Companies pick materials they can track and recycle in a closed loop. This helps them follow global rules about being sustainable. PET can be recycled, and people care more about plastic waste. This makes more people want packaging that is better for the planet. Many companies make Mould that are eco-friendly and cut down on waste. These Mould also help with recycling. Lighter and greener Mould use less material and work better. Social and governance rules, like health and safety, also matter. Companies must be open about where their materials come from. Using ESG rules helps the market match what buyers want and keeps it growing. Sustainability trends push companies to use circular economy ideas. This makes the pet preforms market stronger and ready for the future.

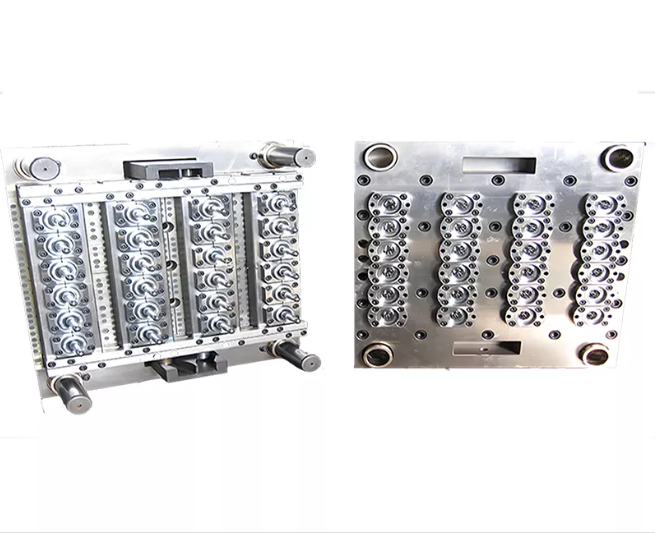

New technology is very important for the pet preform Mould market. Makers use special CAD software and machines to design detailed Mould. These Mould have exact shapes and smooth surfaces. Multi-cavity Mould and hot runner systems help make more products faster. Machines with computers and automation make things more precise and quick. New ways like co-injection molding let makers use more than one material. This gives preforms better protection and cool designs. Research teams keep looking for new materials and ways to make Mould last longer. Quality control and digital checks make sure everything works well. These tech trends help makers meet the need for better preforms.

Rules have a big effect on the pet preform Mould market. Some laws, like those in the EU and US, say packaging must use recycled materials. This means makers use more recycled PET and bio-based PET. Tariffs on steel, aluminum, and plastic make things cost more. This can slow down the supply chain. Makers try to fix this by using local materials and more machines. Following rules is very important, especially for food and drinks. These products need to be safe and clean. Certifications like ISO, FDA, and FSSC 22000 help keep products safe. Changing rules make companies create new Mould designs and greener ways to make things. It is hard to balance being green, keeping costs low, and making good products. These rules change the market and make more companies use green packaging.

Industry demand helps the pet preform Mould market grow. People in developing countries have more money to spend. They want packaging that is easy to use and carry. Online shopping means more strong and light packaging is needed. The drink industry, especially in East Asia, uses a lot of pet preform Mould. This is because people buy lots of bottled water and drinks. The food industry also needs these Mould for safe packaging of oils and sauces. Medicine and beauty companies use pet packaging for their products too. New tech like automation and AI helps lower costs and make better products. Lighter packaging saves money and is better for the planet. Using green materials and recycling helps the market grow. Multi-cavity and smart Mould make more products and better quality. Demand is high in Asia Pacific, North America, and Europe. This is because of green trends and new rules. The pet preforms market is growing fast because of new ideas, more buyers, and better packaging.

The pet preforms market is getting bigger every year. In 2024, the market size was USD 1.2 billion. Experts think it will reach USD 1.9 billion by 2033. The compound annual growth rate (CAGR) is 5.6% from 2026 to 2033. This growth happens because of new technology and green efforts. Bigger factories also help the market grow. The injection molding machine market helps this growth too. Companies buy better moulds to make more preforms. They want to meet the need for high-quality products. From 2025 to 2033, trends show that innovation and efficiency are very important. The market size shows pet preform Mould are strong in the global injection molding machine market.

Many regions help the pet preforms market grow.

North America pet preform moulds market grows fast, especially in Mexico. The United States has the biggest market size. Canada is growing but not as quickly.

North America pet preform moulds market grows because people want more drinks, medicine, and personal care items.

Asia-Pacific countries like China, India, and Southeast Asia grow quickly. This is because of more factories and bigger cities.

Latin America, with Brazil and Mexico, wants more packaged food and drinks.

The Middle East and Africa are new markets. People there want more bottled water and goods.

Asia-Pacific will have a market size over $120 billion by 2033. Its CAGR will be more than 5.8%.

From 2025 to 2033, Asia-Pacific leads in new ideas, modular moulds, and research.

North America pet preform moulds market is a center for technology and efficiency.

Pet preform Mould are used in many areas. The food and beverage industry uses the most pet preforms. Medicine packaging makes the pharmaceutical sector grow fastest. Cosmetics and personal care need new packaging too. The injection molding machine market helps these areas with better moulds and automation. Trends include lighter preforms, saving energy, and custom designs. The table below shows main application sectors and what helps them grow:

Application Sector | Growth Driver / Market Trends 2025-2033 |

|---|---|

Food & Beverage | Biggest market share, lots of drinks, new packaging ideas |

Pharmaceuticals | Fastest growth, more medicine sales, safety needs |

Cosmetics & Personal Care | More demand, new and green packaging solutions |

Regional Driver | Asia-Pacific grows in food, drinks, and cosmetics |

Market Characteristics | Light, strong, recyclable, and green preforms |

The pet preforms market keeps changing with new needs, better moulds, and strong growth in many regions. Experts think the market will keep growing in old and new areas.

The pet preform Mould industry has many Mould types. These Mould help meet different needs in the market. Buyers often want special Mould for their own products. The table below shows some popular Mould types and what they do:

Mould Variant Type | Cavity Range | Key Features and Usage | Material and Components |

|---|---|---|---|

Double lock pneumatic needle valve tube blank Mould | 1 to 72 | Multi-dimensional cone positioning system for consistent plastic thickness | Mould base: P20; Core & cavity: S136, 718 |

Double lock adjustable eccentric pneumatic needle valve preform Mould | 1 to 72 | Ensures uniform PET flow and pressure across cavities using unique hot runner system | Hot runner brands: HASCO, YUDO, HUSKY, local |

Ordinary no-gate preform Mould | 1 to 72 | Standard Mould type for various preform shapes and sizes | High-quality steel materials |

Specific Mould sizes | N/A | 28mm Mould popular for soft drink bottles; 30mm for mineral water; 38mm for juices/yogurt | Preform weight varies from 30ML to 1000ML |

Picking the right Mould type helps make better preforms. Mould with more cavities make more products at once. This lowers the cost for each preform. Good hot runner systems help keep preforms the same quality. Using strong steel makes Mould last longer and keeps them the right shape. Cooling systems and how hard the Mould is to make also matter. These things help make sure the final preforms work well.

Customization changes how companies make pet preforms. Buyers want Mould made for their own bottle shapes and uses. This helps make sure the bottles fit and work right. It also stops mistakes that cost a lot of money. Many buyers like Mould that can make different bottle sizes and neck shapes. This saves money and time because they do not need new Mould.

Some important things buyers look for are:

Custom designs for special bottle shapes and uses.

Smaller orders and split deliveries to help manage stock.

Working with other buyers or local sellers for easier orders.

Knowing what is needed for different liquids, like neck size and wall strength, to stop problems.

Clear info about resin sources and certifications for good quality.

Mould that can change for local rules and tastes.

Good support after buying, clear trade rules, and quality checks to lower risks.

Automation and digital tools to make things faster and cut down on waiting.

Good supply chains and spare parts to stop delays.

Note: Buyers check factories, certificates, and customer reviews before picking a supplier. They ask for strong quality checks and want to track each batch. They also want good help after buying.

Digitalization has changed the pet preform Mould industry a lot. New digital tools in machines help make preforms more exact. Automation, like robots and quick Mould changes, makes work faster and easier.

Makers use AI and machine learning to make things better as they go. These tools help keep quality high, waste low, and fix problems before they happen. Digitalization lets companies make many shapes and sizes for different uses.

Digital tools let workers watch and control the whole process in real time. This makes making Mould faster, cheaper, and better for the planet. Companies can quickly change what they make to fit new needs.

Smart factories use digital systems to make blow molding better and work faster. Because of this, the industry can give high-quality, custom Mould for every need. This helps the pet preforms market keep growing.

Manufacturers in the pet preforms market have many supply chain problems. They need to talk with overseas suppliers, like those in China. Sometimes, people do not understand technical details. This can lead to expensive mistakes. Bilingual technical drawings help English-speaking clients and Chinese engineers work together. Guangchao Mould company check machine and preform details before making anything. This helps stop problems with parts not fitting. Teams use modern tools to talk often and watch how things are made. This helps them find and fix problems early.

Innovation helps the pet preforms market grow. Top companies use strong materials like steel and aluminum for moulds. These materials last a long time and need less fixing. Special cooling channels in moulds make things faster and use less water. Lighter PET preforms save money but still work well. Some moulds can change easily to make different products.

Green ideas help save energy and water. Companies use more recycled PET to help the planet. Some factories put lots of recycled PET back into the market. Always trying to do better and use new tech sets the standard for others. Companies offer full solutions from design to making and checking PET preform moulds.

New products use ISO hot runner tech, KoolTrack™ cooling, and PiCOOL™ cooling. These make cooling better, speed up work, and help make more products. Special coatings and changeable moulds help moulds last longer and make less waste. Good hot runner systems and cold water channels make things more exact and fast. Companies give full solutions to help customers and make working together easier.

The pet preforms market is getting bigger each year. This happens because of sustainability, new technology, and more people wanting preforms. B2B customization lets buyers pick their own preform designs and how they are made. Buyers can also choose rules for safety and quality. To do well, buyers should tell suppliers what they need early. They should ask for samples and pick suppliers who check quality and help after buying. The market will use more recycled pet and machines that work by themselves. Preforms will be lighter and easier to use. Companies that try new ideas and care about the planet will find more chances in the pet preforms market.