Views: 0 Author: Site Editor Publish Time: 2024-11-15 Origin: Site

Choosing the right Home Appliance Mould for your washing machine is a critical decision that can significantly impact the performance, durability, and cost-efficiency of the final product. The selection process involves understanding the various types of moulds available, the materials used, and the specific requirements of your washing machine components. With the rise of advanced manufacturing technologies, the options for Plastic mould production have expanded, offering manufacturers more flexibility and precision. In this research paper, we will explore the key factors to consider when selecting a mould for washing machine parts, including material selection, mould design, and manufacturing processes. We will also highlight the importance of working with experienced mould manufacturers to ensure optimal results.

In this comprehensive guide, we will delve into the technical aspects of Home Appliance Mould selection, focusing on the critical parameters that influence mould performance. Additionally, we will provide insights into the latest trends in the moulding industry, particularly in the context of washing machine manufacturing. Whether you are a product designer, engineer, or procurement specialist, this paper will equip you with the knowledge needed to make informed decisions.

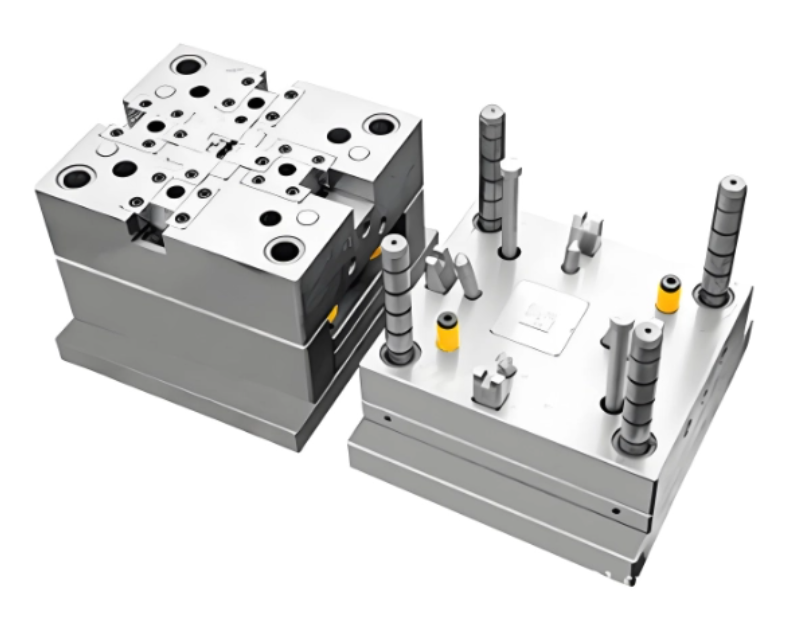

Moulds play a pivotal role in the manufacturing of washing machines, particularly in the production of plastic components such as the outer body, control panels, and internal parts like the drum and agitator. The quality of the mould directly affects the dimensional accuracy, surface finish, and overall durability of these components. A well-designed Plastic mould ensures that the parts fit together seamlessly, reducing the need for post-production adjustments and improving the efficiency of the assembly process.In the context of washing machines, the most commonly used materials for moulded parts are thermoplastics such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). These materials offer excellent strength, chemical resistance, and impact resistance, making them ideal for both external and internal components. The choice of material is closely linked to the design of the mould, as different plastics have varying shrinkage rates, flow characteristics, and cooling requirements. For more detailed information on plastic moulding processes, you can refer to our Plastic mould.

The first and foremost consideration when selecting a Home Appliance Mould is the material that will be used to produce the washing machine components. As mentioned earlier, thermoplastics like PP, ABS, and PC are commonly used due to their excellent mechanical properties. However, the choice of material should also take into account factors such as cost, environmental impact, and recyclability. For instance, polypropylene is a cost-effective option with good chemical resistance, while polycarbonate offers superior impact resistance but at a higher cost.In addition to the plastic material, the mould itself can be made from various materials, including steel, aluminum, and beryllium copper. Steel is the most commonly used material for high-volume production due to its durability and resistance to wear. Aluminum, on the other hand, is often used for prototyping or low-volume production because it is easier to machine and offers faster cycle times. Beryllium copper is sometimes used in areas of the mould that require rapid heat dissipation, such as core inserts.

The design of the mould is another critical factor that influences the quality and performance of the final product. A well-designed mould should ensure uniform material flow, minimize defects such as warping or sink marks, and allow for efficient cooling to reduce cycle times. The complexity of the mould design depends on the geometry of the washing machine components. For example, parts with intricate shapes or undercuts may require the use of multi-cavity or multi-part moulds, which can increase the cost and lead time of the mould-making process.Another important aspect of mould design is the gating system, which controls the flow of molten plastic into the mould cavity. The location and size of the gate can significantly affect the quality of the final part, particularly in terms of surface finish and dimensional accuracy. Additionally, the cooling system within the mould plays a crucial role in determining the cycle time and overall productivity of the moulding process. Proper cooling channel design can help to reduce cycle times and improve the consistency of the moulded parts.

The manufacturing process used to produce the Home Appliance Mould is another key consideration. Injection moulding is the most common process used for washing machine components, as it allows for high-volume production with excellent repeatability and precision. However, other processes such as blow moulding or compression moulding may be used for specific parts, depending on the material and design requirements.When selecting a mould manufacturer, it is important to consider their capabilities in terms of precision machining and quality control. The tolerances required for washing machine components are typically very tight, particularly for parts that need to fit together with minimal gaps or misalignment. A reputable mould manufacturer should have advanced CNC machining equipment and a robust quality control system in place to ensure that the moulds meet the required specifications.

Given the complexity and precision required in mould design and manufacturing, it is essential to work with an experienced mould manufacturer who has a proven track record in the home appliance industry. A reliable manufacturer will not only provide high-quality moulds but also offer valuable insights during the design phase to optimize the performance and cost-efficiency of the final product.In addition to technical expertise, it is important to choose a manufacturer who can offer comprehensive support throughout the entire product development process, from initial design to final production. This includes services such as prototyping, material selection, and mould testing. By partnering with a reputable mould manufacturer, you can ensure that your washing machine components are produced to the highest standards of quality and durability. For more information on mould manufacturing capabilities, visit our capabilities page.

In conclusion, selecting the right Home Appliance Mould for your washing machine is a multifaceted process that requires careful consideration of material selection, mould design, and manufacturing processes. By understanding the key factors that influence mould performance, you can make informed decisions that will improve the quality, durability, and cost-efficiency of your washing machine components. Additionally, working with an experienced mould manufacturer is crucial to ensuring that the moulds meet the required specifications and deliver consistent results over time. To learn more about the different types of Home Appliance Mould available, explore our product offerings.