Views: 0 Author: Site Editor Publish Time: 2025-01-10 Origin: Site

In the ever-evolving automotive industry, the role of automotive moulding has become increasingly significant, particularly in the design and functionality of car headlights, tail lights, and bumper moulds. These components are not just about aesthetics; they play a crucial role in vehicle safety, energy efficiency, and overall performance. As we look towards the future, several key trends are emerging in automotive moulding that are set to redefine the industry.

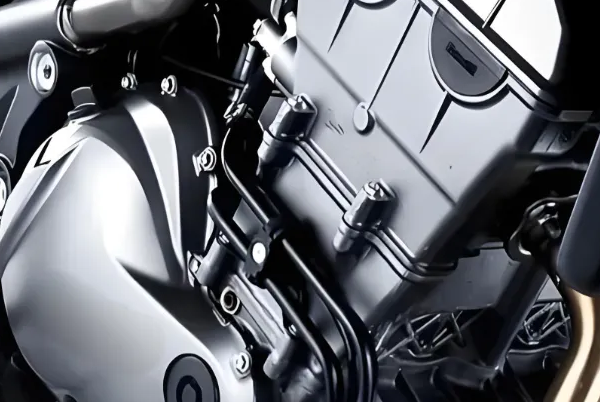

Automotive moulding refers to the process of creating and installing various plastic and metal components in vehicles, including trim pieces, seals, and functional elements like headlights and tail lights. This process is crucial for both the aesthetic appeal and the functional integrity of vehicles.

The importance of automotive moulding in vehicle manufacturing cannot be overstated. It not only contributes to the visual appeal of vehicles but also plays a critical role in durability and performance. For instance, well-designed moulds can enhance the fit and finish of vehicle components, reducing the likelihood of issues like water leakage or wind noise. Moreover, advancements in moulding technology have allowed for the production of lighter and more energy-efficient components, aligning with the automotive industry’s push towards sustainability.

In recent years, there has been a significant shift towards more sustainable and efficient moulding processes. Manufacturers are increasingly adopting techniques like injection compression moulding and in-mould decorating to reduce waste and energy consumption. These methods not only lower the environmental impact but also improve the quality and precision of the moulded parts.

The evolution of headlight technology has been remarkable, with significant advancements in both functionality and design. LED and laser technologies have become prominent, offering greater energy efficiency and longer lifespan compared to traditional halogen bulbs. LEDs consume less power and provide brighter illumination, enhancing safety during night driving. Laser headlights, on the other hand, offer even greater efficiency and can project a more focused beam, significantly improving visibility.

Adaptive headlights are another innovation that is gaining traction. These systems adjust the direction and intensity of the light beam based on the vehicle’s speed and steering angle, providing optimal illumination under various driving conditions. For instance, they can dim or redirect the light to avoid blinding oncoming drivers while maximizing visibility in turns.

Tail lights have also seen significant innovations, particularly in terms of design and functionality. The integration of LED technology has become standard, offering faster illumination and lower power consumption. This is particularly important for safety, as LED tail lights respond more quickly than traditional bulbs, reducing the risk of rear-end collisions.

Beyond safety, tail light design has become a key aspect of vehicle branding. Unique light signatures are now a common feature, allowing manufacturers to create a distinct identity for their vehicles. This is not just about aesthetics; it also helps in making vehicles more recognizable, enhancing safety and brand visibility.

Bumper moulding is undergoing significant changes, driven by advancements in materials and design technology. The use of more flexible and durable materials is becoming common, allowing for bumpers that can better withstand impacts without cracking or breaking. This is not only a safety feature but also a cost-saving measure, as more resilient bumpers require less frequent replacement.

Design innovation is also playing a crucial role in bumper moulding. Streamlined designs that integrate more seamlessly with the overall vehicle body are becoming popular. These designs not only enhance the aesthetic appeal of vehicles but also improve aerodynamics, contributing to better fuel efficiency.

The trends in automotive moulding are having a profound impact on vehicle safety and efficiency. Advanced headlight technologies, such as adaptive systems, are enhancing visibility and reducing the risk of accidents. Similarly, innovations in tail light design are improving response times, a critical factor in rear-end collision prevention.

Efficiency is also being improved through the use of lighter and more durable materials. This not only enhances the performance of vehicles but also contributes to better fuel economy, aligning with global sustainability goals.

The influence of moulding trends extends beyond safety and efficiency; it also significantly impacts the aesthetic and functional design of vehicles. Unique headlight and tail light designs are becoming integral to vehicle branding, allowing manufacturers to create a distinct identity for their models. This is not just about aesthetics; it also plays a crucial role in functional design, as these elements need to be integrated seamlessly with the overall vehicle structure.

One of the most significant impacts of moulding trends is on vehicle weight and aerodynamics. The shift towards lighter and more flexible materials is helping to reduce the overall weight of vehicles, which is a key factor in improving fuel efficiency. Additionally, streamlined bumper designs are enhancing aerodynamics, further contributing to better performance and lower energy consumption.

The future of automotive moulding is set to be shaped by emerging materials that offer a range of benefits. For instance, the use of natural fibre composites is gaining attention due to their lightweight and biodegradable properties. These materials not only help in reducing the environmental impact but also offer comparable performance to traditional composites.

Another promising area is the development of high-performance polymers that can withstand the rigours of automotive use while being lighter and more cost-effective than metal. These materials are ideal for components like bumpers and interior trim, where weight reduction is crucial for overall vehicle efficiency.

Technological advancements are set to play a crucial role in the future of automotive moulding. Innovations such as 3D printing and advanced robotics are expected to revolutionize the manufacturing process, allowing for greater design flexibility and efficiency. 3D printing, in particular, offers the potential for rapid prototyping and customization, enabling manufacturers to produce complex parts with minimal waste.

Moreover, the integration of smart technologies into moulded components is an exciting prospect. Imagine bumpers with built-in sensors that can detect obstacles or headlights that adjust automatically based on driving conditions. These innovations could significantly enhance vehicle safety and functionality.

The integration of smart technologies into automotive moulding is already underway, with several exciting developments on the horizon. For instance, headlight systems that can adapt their intensity and direction based on road conditions are becoming a reality. These systems not only improve safety by providing optimal illumination but also reduce energy consumption, contributing to overall vehicle efficiency.

Similarly, tail lights with integrated communication features are being developed. These lights can signal to other drivers when a vehicle is slowing down or changing lanes, enhancing safety and reducing the likelihood of accidents. The integration of such smart technologies into automotive moulding represents a significant step forward in the evolution of vehicle design and functionality.

The future of automotive moulding is bright, with numerous trends and innovations set to transform the industry. From advanced headlight and tail light technologies to innovative bumper designs, these developments are not only enhancing vehicle safety and efficiency but also influencing aesthetic and functional design.

As we move forward, the integration of emerging materials and smart technologies will play a crucial role in shaping the next generation of vehicles. These innovations promise to deliver not only better performance and lower environmental impact but also a more connected and intelligent driving experience.

In conclusion, the ongoing trends in automotive moulding are laying the groundwork for a more advanced, efficient, and sustainable automotive industry. As manufacturers continue to embrace these developments, we can expect to see vehicles that are not only safer and more efficient but also more attuned to the needs and preferences of modern drivers.