Views: 0 Author: Site Editor Publish Time: 2024-11-29 Origin: Site

Plastic moulding revolutionized the automotive industry by providing manufacturers with a wide range of options for producing high-quality parts. This article explores the benefits of plastic moulding in automotive parts production.

Plastic moulding is a process that involves creating parts by injecting molten plastic into a mould, allowing for the mass production of complex shapes and designs. The automotive industry has embraced this technology due to its numerous advantages, including cost-effectiveness, lightweight materials, and design flexibility.

With the increasing demand for fuel-efficient vehicles and the need to reduce emissions, manufacturers are turning to plastic moulding as a viable solution. This article delves into the benefits of plastic moulding in automotive parts production and how it has transformed the industry.

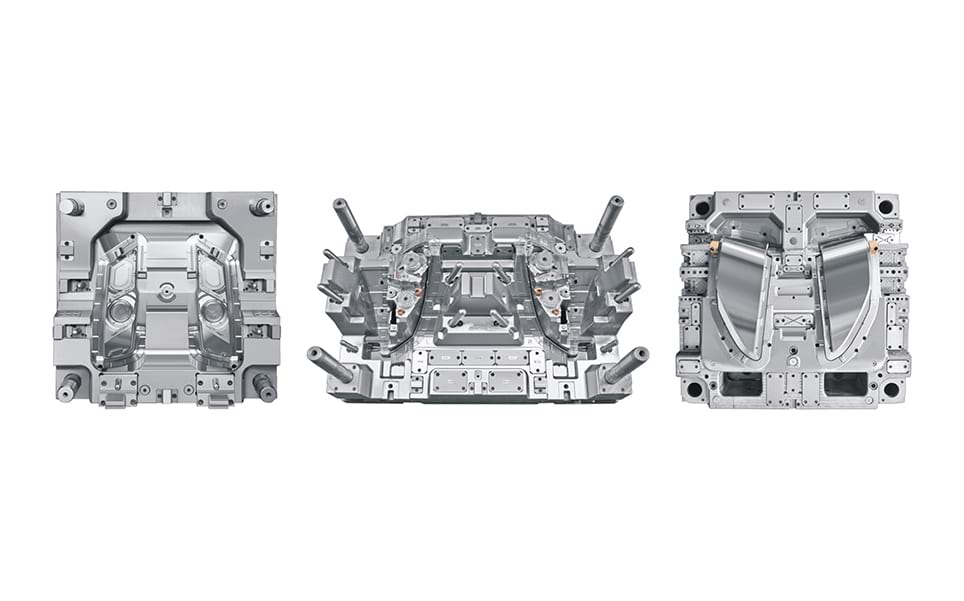

Plastic moulding is a manufacturing process that involves the creation of parts by injecting molten plastic into a mould. This process allows for the mass production of complex shapes and designs, making it an ideal solution for the automotive industry.

Plastic moulding has revolutionized the production of automotive parts by providing manufacturers with a cost-effective and efficient way of producing high-quality parts. The process involves several steps, including designing the mould, heating the plastic, injecting the plastic into the mould, cooling the mould, and removing the finished product.

Each step is crucial in ensuring that the final product meets the desired specifications and quality standards. Plastic moulding is a versatile process that can be used to create a wide range of parts, including dashboards, door panels, bumpers, and interior trim.

The use of plastic moulding in automotive parts production has several advantages, including cost-effectiveness, lightweight materials, and design flexibility. These benefits have made plastic moulding a popular choice for manufacturers looking to produce high-quality parts at a lower cost and with greater efficiency.

Plastic moulding has revolutionized the automotive industry by providing manufacturers with a cost-effective and efficient way of producing high-quality parts.

One of the main advantages of plastic moulding is its ability to produce parts in large quantities at a lower cost than traditional manufacturing methods. This is due to the speed and efficiency of the moulding process, which allows for the mass production of complex shapes and designs.

Another advantage of plastic moulding is its versatility, as it can be used to create a wide range of parts, from small components to large body panels. This flexibility allows manufacturers to create customized parts that meet the specific needs of their customers.

In addition, plastic moulding produces parts that are lighter and more durable than traditional metal parts, which can help to improve fuel efficiency and reduce emissions. Plastic parts are also less prone to corrosion and rust, which can help to extend the lifespan of vehicles.

Overall, plastic moulding offers several advantages for automotive parts production, including cost-effectiveness, versatility, and durability. As the automotive industry continues to evolve, plastic moulding will likely play an increasingly important role in the production of high-quality parts that meet the needs of manufacturers and consumers alike.

Plastic moulding is a versatile manufacturing process that has numerous applications in the automotive industry. One of its primary uses is in the production of interior components, such as dashboards, door panels, and centre consoles.

These parts are often made from acrylonitrile butadiene styrene (ABS) or polycarbonate (PC), which are both durable and resistant to impact and scratches. Plastic moulding allows for the creation of complex shapes and designs, which can enhance the aesthetic appeal of a vehicle’s interior.

Another application of plastic moulding in the automotive industry is in the production of exterior components, such as bumpers, grilles, and headlight housings. These parts are often made from polypropylene (PP) or polyamide (PA), which are both lightweight and resistant to UV radiation and chemicals.

Plastic moulding allows for the creation of parts that are not only functional but also visually appealing, as they can be painted or coated with a variety of finishes.

Plastic moulding is also used in the production of under-the-hood components, such as air intake manifolds and fuel tanks. These parts are often made from nylon (PA) or polyphenylene sulphide (PPS), which are both strong and resistant to high temperatures and chemicals. Plastic moulding allows for the creation of parts that are not only lightweight but also able to withstand the harsh conditions of an engine bay.

Overall, plastic moulding is a versatile and cost-effective manufacturing process that has numerous applications in the automotive industry. Its ability to create complex shapes and designs, while also producing parts that are durable and visually appealing, makes it an essential tool for automotive manufacturers looking to produce high-quality vehicles.

When choosing plastic moulding for automotive parts production, there are several factors to consider to ensure the best possible outcome. One of the most important factors is the type of plastic material to be used.

Different plastics have different properties, such as strength, flexibility, and resistance to heat and chemicals. It is important to choose a plastic material that is suitable for the specific application and will meet the required performance standards.

Another factor to consider is the complexity of the part design. Plastic moulding is a highly versatile manufacturing process that can produce parts with complex shapes and designs. However, more complex designs may require more intricate moulds, which can increase production costs and lead times.

It is important to balance the need for complex designs with the practical considerations of cost and feasibility.

The size and quantity of parts to be produced is also an important factor to consider. Plastic moulding is a highly efficient manufacturing process that can produce large quantities of parts quickly and cost-effectively. However, the size and complexity of the parts being produced can affect production rates and costs.

It is important to choose a mould size and design that is suitable for the desired production volume and will minimize waste and costs.

Finally, it is important to consider the quality and consistency of the final product. Plastic moulding can produce parts with high levels of accuracy and consistency, but it is important to choose a reputable moulding company with experience in automotive parts production to ensure the best possible outcome.

It is also important to conduct thorough testing and quality control throughout the production process to ensure that the final product meets the required standards.

Plastic moulding has transformed the automotive industry by providing manufacturers with a cost-effective and efficient way of producing high-quality parts. Its numerous advantages, including design flexibility, lightweight materials, and cost-effectiveness, have made it a popular choice for manufacturers looking to produce high-quality parts at a lower cost and with greater efficiency.

The versatility of plastic moulding makes it an ideal solution for the production of various automotive parts, from small components to large body panels. As the automotive industry continues to evolve, plastic moulding will likely play an increasingly important role in the production of high-quality parts that meet the needs of manufacturers and consumers alike.