Views: 0 Author: Site Editor Publish Time: 2025-01-24 Origin: Site

Injection molding is a manufacturing process for producing parts in large volumes. This process is commonly used for plastic parts but can also be used to make parts from other materials, such as metals. The injection molding process involves injecting material into a mold, which is then cooled and solidified to create the final part.

Injection molding has many benefits, including:

– The ability to produce parts in large volumes quickly and efficiently.

– The ability to produce parts with complex shapes and features.

– The ability to use a wide range of materials.

– The ability to achieve tight tolerances and high-quality surface finishes.

Injection molding is widely used in a variety of industries, including automotive, aerospace, consumer goods, and medical devices.

The injection molding process involves several steps, including:

1. Material preparation: The material, typically in the form of pellets or granules, is dried and then fed into the injection molding machine.

2. Injection: The material is heated until it becomes molten and is then injected into the mold under high pressure.

3. Cooling: The mold is cooled, allowing the material to solidify and take the shape of the mold.

4. Ejection: Once the part has cooled, it is ejected from the mold using ejector pins or plates.

5. Finishing: The part may undergo secondary operations, such as trimming, painting, or assembly, to achieve the desired final product.

The injection molding process is highly efficient and can produce parts at a rate of several hundred to several thousand parts per hour, depending on the size and complexity of the part.

– CNC machining is a manufacturing process that uses computer-controlled machines to create parts from a variety of materials, including plastic, metal, and wood.

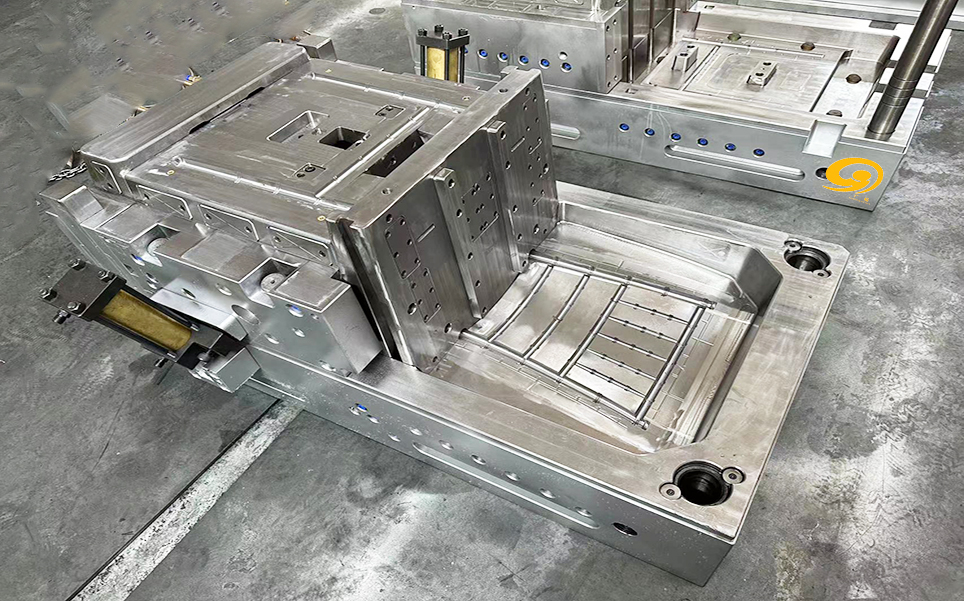

– In injection molding, CNC machining is often used to create the molds used in the injection molding process.

– CNC machining allows for precise and accurate mold creation, which is critical for producing high-quality parts.

– CNC machining can also be used for secondary operations, such as trimming and finishing, to achieve the desired final product.

CNC machining plays a critical role in the injection molding process by creating precise and accurate molds that are used to produce parts. The use of CNC machining allows for tight tolerances and complex shapes, which are essential for high-quality parts.

In addition to creating molds, CNC machining can also be used for secondary operations, such as trimming and finishing, to achieve the desired final product. This allows for greater flexibility and customization in the injection molding process.

CNC machining is a highly efficient and cost-effective method for creating molds and producing parts, making it an essential component of the injection molding process.

There are several benefits to using CNC machining in the injection molding process, including:

– Precision and accuracy: CNC machining allows for precise and accurate mold creation, which is critical for producing high-quality parts.

– Flexibility: CNC machining can be used to create molds for a wide range of parts, making it a flexible and versatile option for injection molding.

– Customization: CNC machining allows for greater customization in the injection molding process, enabling the creation of complex shapes and tight tolerances.

– Efficiency: CNC machining is a highly efficient and cost-effective method for creating molds and producing parts, making it an essential component of the injection molding process.

CNC machining plays a critical role in the injection molding process by creating precise and accurate molds that are used to produce parts. The use of CNC machining allows for tight tolerances and complex shapes, which are essential for high-quality parts.

In addition to creating molds, CNC machining can also be used for secondary operations, such as trimming and finishing, to achieve the desired final product. This allows for greater flexibility and customization in the injection molding process.

CNC machining is a highly efficient and cost-effective method for creating molds and producing parts, making it an essential component of the injection molding process.