Views: 0 Author: Site Editor Publish Time: 2024-11-11 Origin: Site

Motorcycles are becoming an increasingly popular mode of transportation in today's society, driving higher demand for motorcycles and motorcycle parts and relevant plastic injection molds. This includes molds for components such as tail lights, rear lamps, light guide strips, thick-wall molds, and fenders.

Today, leading motorcycle manufacturers such as Harley-Davidson, Yamaha, and Honda dominate the market, with Bajaj Motorcycles also securing a significant share. In response, Guangchao Mould has established partnerships with these manufacturers, providing high-quality headlamp and rear lamp molds to support their production needs.

A motorcycle parts mold is a specialized tool or form used in the plastic injection molding process to manufacture various plastic components of motorcycles. This mold is typically made from hardened steel or aluminum, designed to withstand high pressure and repeated use. Each mold is custom-made to produce a specific part, such as a tail light, fender, light guide strip, or other plastic components used in motorcycles.

The motorcycle parts mold consists of two main halves (the cavity and core) that come together to create a hollow space in the shape of the desired part. During the injection molding process, molten plastic is injected into this space, where it cools and solidifies, taking on the exact shape and details of the mold. Once cooled, the mold opens, and the part is ejected, ready for further assembly or finishing.

The motorcycle parts mold material also need to pay special attention to the selection, Otherwise, there will be products and actual molding do not meet the requirements . Headlight housing base mould always use P20, headlight or tail light lampshade mold always use ESR2343 to reaching high polishing request . Assuming that the customer's requirements are not high, we can also use 718HH material .

For motorcycle parts made through injection molding, several types of plastic materials stand out for their durability, impact resistance, and aesthetic qualities. Here are some of the best plastic materials commonly used:

Properties: ABS is known for its toughness, impact resistance, and ease of molding. It also has good heat resistance and can be plated or painted for improved aesthetics.

Common Uses: Ideal for body panels, fenders, and fairings due to its durability and smooth finish.

Properties: Polypropylene is lightweight, resistant to chemicals, and has excellent fatigue resistance, making it a cost-effective option. It’s also highly flexible and resistant to cracking.

Common Uses: Often used for covers, internal fittings, and non-structural components that benefit from its lightweight and flexible nature.

Properties: Polycarbonate is extremely tough, has high impact resistance, and is transparent, making it an ideal choice for parts that require visibility and durability.

Common Uses: Frequently used in headlight and tail light covers due to its clarity and resistance to impact and scratches.

Properties: Nylon is highly durable, with excellent resistance to wear, heat, and chemicals. It’s slightly flexible, which helps it withstand vibrations and impacts.

Common Uses: Suited for gears, brackets, and structural components that experience high stress or need additional strength.

Properties: TPU is both flexible and highly resistant to abrasion, tears, and oil. It’s also UV resistant, which is important for outdoor exposure.

Common Uses: Often used in protective parts, gaskets, and seals, and for components requiring both flexibility and resilience.

Properties: PPS offers excellent heat and chemical resistance, making it ideal for parts exposed to extreme environments. It also has dimensional stability and can endure high mechanical stress.

Common Uses: Common in engine components and parts near the exhaust system where higher heat resistance is needed.

Properties: Known for its optical clarity and UV resistance, acrylic is durable and scratch-resistant, making it a great alternative to glass in motorcycle parts.

Common Uses: Used for lenses, light covers, and other transparent components that benefit from its clarity and durability.

The best material choice depends on the specific function of the part, the conditions it will face, and any aesthetic requirements. Generally, ABS, PP, and PC are among the most popular due to their strength, moldability, and cost-effectiveness, while materials like PPS and TPU are selected for specialized applications requiring additional resistance to heat, chemicals, or mechanical wear.

Guangchao Mould as a professional motorcycle parts mold supplier and manufacturer , we have a long-term relationship with some famous motorcycle brands ,like Yamaha ,Honda ,Harley-Davidson .

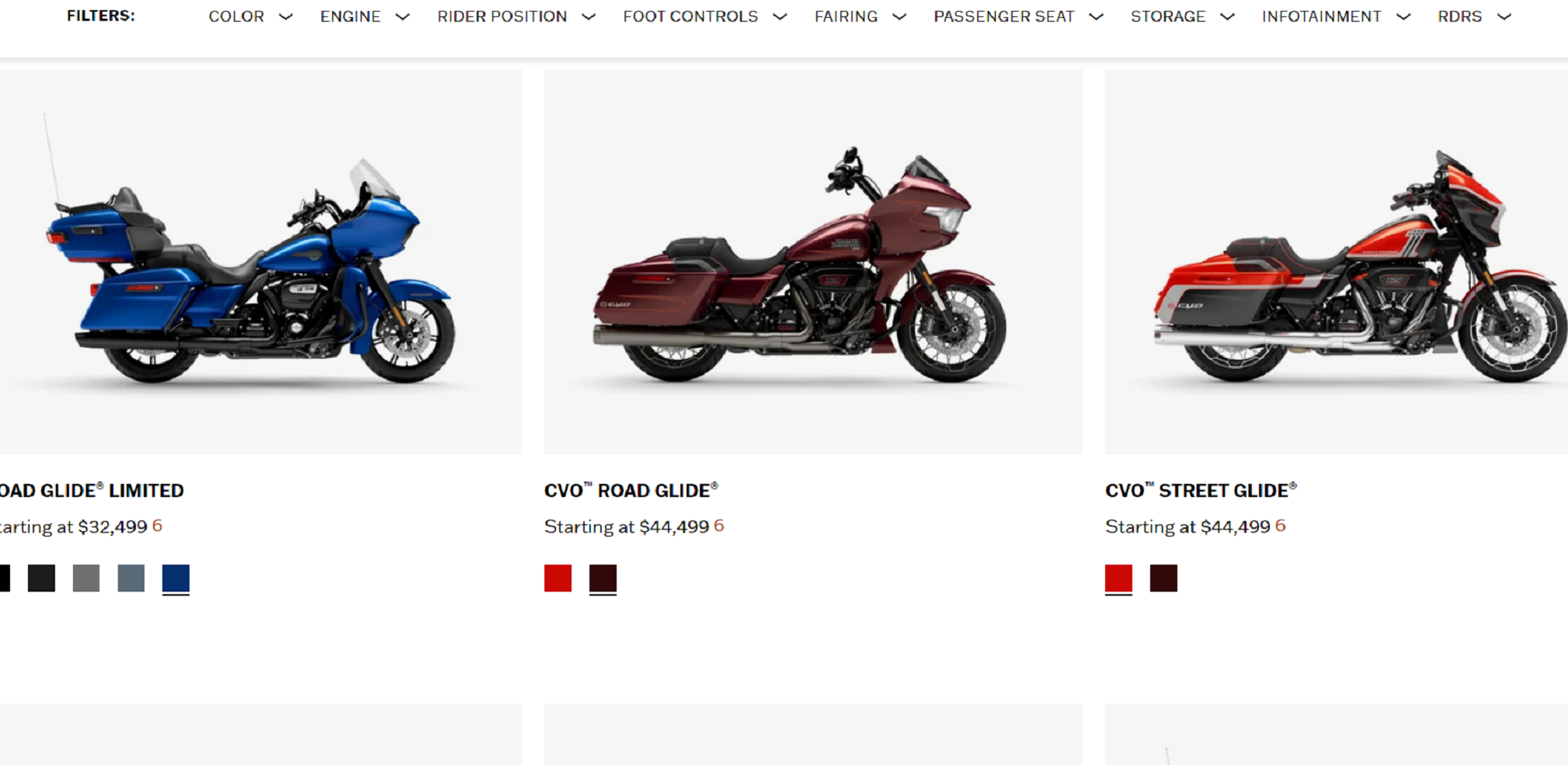

Here are top 3 famous motorcycle manufacturer :

The top motorcycle manufacturer in the United States, with a market share of around 27.1% as of December 2023.

Website: https://www.harley-davidson.com/us/en/index.html

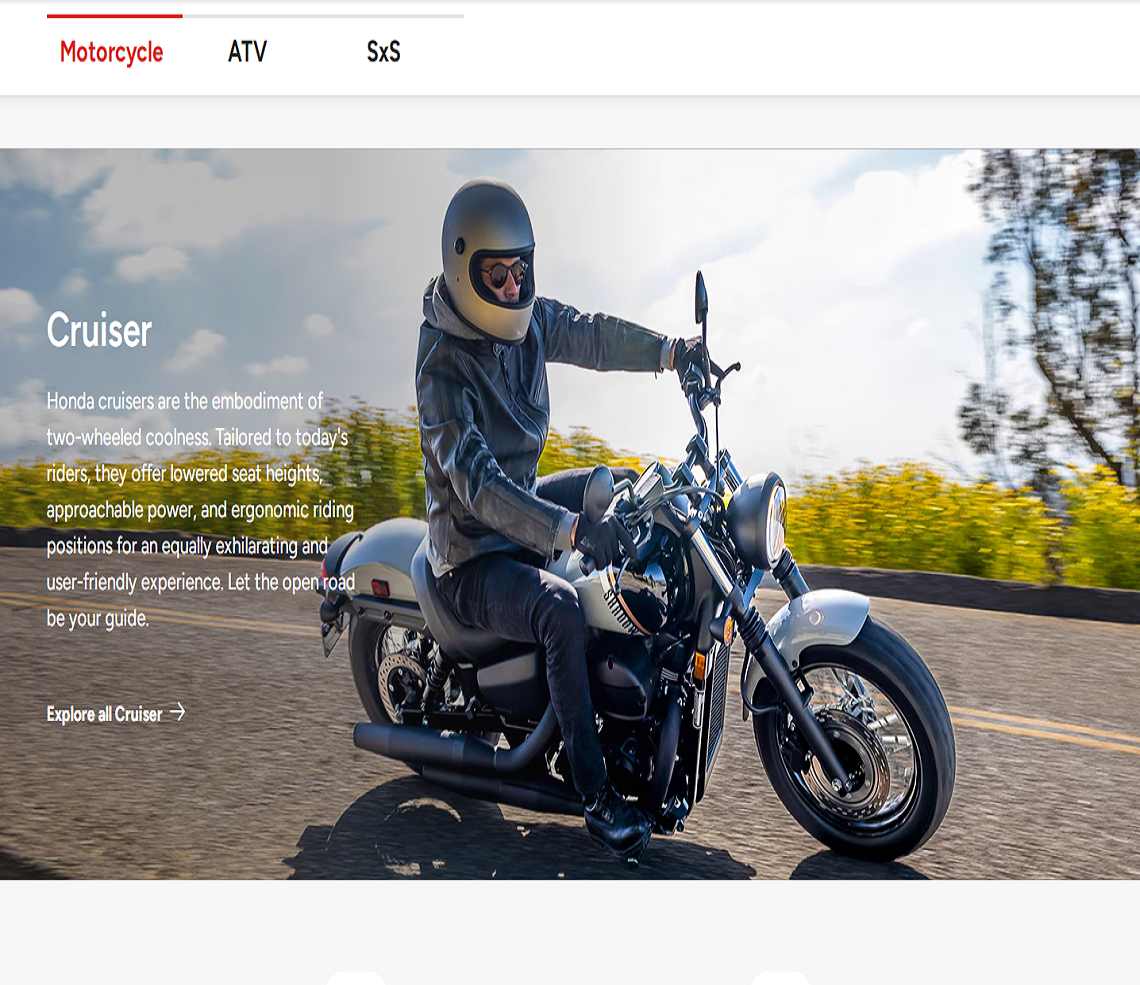

A Japanese multinational corporation that produces a wide range of vehicles and engines, including the best-selling motorcycle of all time, the Honda Super Cub.

Website : https://powersports.honda.com/motorcycle

A Japanese manufacturer known for its reliable and affordable small-capacity motorcycles. Yamaha is considered to be one of the most reliable motorcycle brands.

Website : https://yamahamotorsports.com/

Except the motor brands I mentioned above , Bajaj motorcycle in India is also a popular brand.

Bajaj Group is an Indian multinational conglomerate founded by Jamnalal Bajaj in Mumbai in 1926. The group comprises 40 companies and its flagship company Bajaj Auto is ranked as the world's fourth largest two- and three-wheeler manufacturer.

Plastic injection molds for motorcycle parts consist of several key components, each serving a specific role in the molding process.

Mold base

Cavity and Core

Ejector Pins

Sleeves,Center Pins

Core Pins

Sprue bushings ,Gates ,and other components

Date Mark inserts ,Recycle Mark Inserts ,Pins with Gas Vent

Undercut,Plates

Leader Components,Components for Ejector Space

Mold Opening Controllers

Cooling or Heating Components

Accessories,Others

Components of Large Mold,Die Casting

Cylinder

Each of these components plays a crucial role in producing high-quality, durable motorcycle parts, such as tail lights, fenders, and other molded components.

In conclusion, the increasing popularity of motorcycles has driven demand for both motorcycle parts and the specialized plastic injection molds used to manufacture them. Motorcycle molds are carefully designed tools that play a crucial role in producing high-quality, durable parts, including lights, fenders, and structural components.

Selecting the appropriate materials—such as ABS, PP, and PC—ensures that these parts meet the rigorous demands of durability, impact resistance, and aesthetics. Renowned manufacturers like Harley-Davidson, Honda, and Yamaha, alongside brands like Bajaj, rely on high-quality molds to maintain their standards.

Companies like Guangchao Mould have established strong partnerships with these leading brands, showcasing the importance of precision mold manufacturing in supporting the global motorcycle market.