Views: 0 Author: Site Editor Publish Time: 2024-12-13 Origin: Site

The manufacturing of disposable syringes is a cornerstone of modern medical practices, ensuring safe and hygienic administration of medications and vaccines. Central to this process is the use of high-precision medical mould, which guarantees the production of consistent, reliable, and sterile components. These moulds are not just tools but the backbone of quality assurance in syringe manufacturing. This article explores the critical role of medical moulds in the production of disposable syringes, delving into their design, materials, and the technological advancements that make them indispensable.

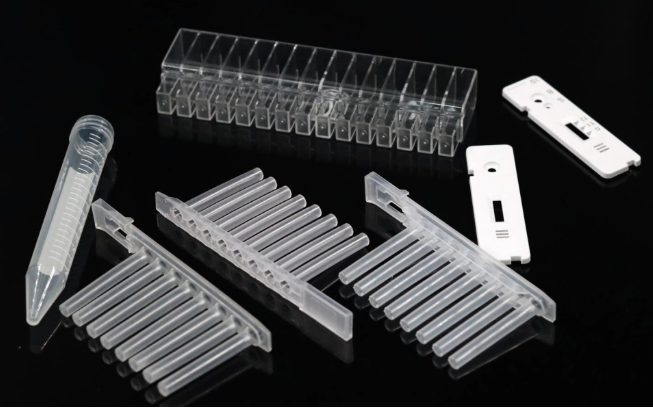

Medical moulds are engineered to produce syringe components with extreme precision. The barrel, plunger, and needle hub must fit together seamlessly to ensure proper functionality. Any deviation in dimensions can lead to leakage, contamination, or malfunction. Advanced moulding technologies, such as high-speed injection moulding, enable the production of components with tolerances as tight as ±0.01 mm. This level of precision is crucial for maintaining the sterility and reliability of disposable syringes.

The materials used in medical moulds are carefully selected to meet stringent medical standards. Typically, stainless steel and hardened tool steel are used due to their durability, corrosion resistance, and ability to withstand high-pressure injection processes. Additionally, the mould surfaces are often treated with specialized coatings to enhance their wear resistance and reduce friction, ensuring a longer lifespan and consistent performance.

Sterility is a non-negotiable requirement in the production of disposable syringes. Medical moulds are designed to operate in cleanroom environments, where contamination risks are minimized. The moulds themselves are subjected to rigorous cleaning and maintenance protocols to ensure they do not introduce any impurities into the manufacturing process. This focus on hygiene is critical for meeting regulatory standards and safeguarding patient health.

The field of medical moulding has seen significant technological advancements in recent years. Innovations such as multi-cavity moulds, hot runner systems, and automation have revolutionized the production of disposable syringes. Multi-cavity moulds allow for the simultaneous production of multiple components, significantly increasing efficiency. Hot runner systems eliminate the need for runners, reducing material waste and cycle times. Automation further enhances precision and consistency while reducing labor costs.

The design of medical moulds for disposable syringes is inherently complex. Each component must be engineered to exact specifications, taking into account factors such as material shrinkage, cooling rates, and ejection mechanisms. Advanced CAD software and simulation tools are often used to optimize mould designs, ensuring they meet all functional and regulatory requirements.

High-quality medical moulds represent a significant investment. The costs are driven by the need for precision machining, high-grade materials, and advanced technologies. However, these costs are offset by the moulds' durability and the high volumes of syringes they can produce. Manufacturers often conduct cost-benefit analyses to determine the optimal balance between initial investment and long-term returns.

Medical moulds must comply with stringent regulatory standards, such as ISO 13485 and FDA guidelines. These standards govern everything from material selection to manufacturing processes and quality control. Compliance is not just a legal requirement but also a critical factor in building trust with healthcare providers and patients.

As the medical industry moves towards sustainability, there is a growing focus on eco-friendly materials and processes in medical moulding. Biodegradable plastics and energy-efficient moulding technologies are being explored to reduce the environmental impact of disposable syringes. These initiatives align with global efforts to promote sustainable healthcare practices.

The integration of smart technologies, such as IoT and AI, is transforming the field of medical moulding. IoT-enabled moulds can monitor real-time production parameters, enabling predictive maintenance and reducing downtime. AI algorithms can analyze production data to optimize processes and improve quality control, setting new benchmarks for efficiency and reliability.

Medical moulds are indispensable in the manufacturing of disposable syringes, ensuring precision, sterility, and compliance with regulatory standards. From material selection to technological advancements, every aspect of medical moulding is geared towards producing high-quality, reliable syringe components. As the industry evolves, innovations in sustainability and smart technologies promise to further enhance the capabilities of medical moulds. For manufacturers looking to excel in this field, investing in advanced plastic mould solutions is not just an option but a necessity.