Our Categories

Household Injection Mould Suppliers

Household Injection Mould Suppliers

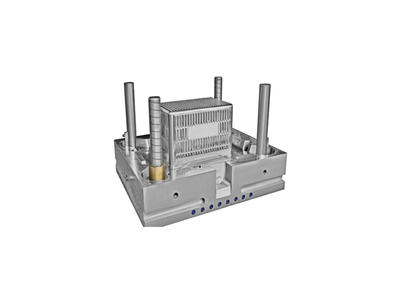

In Taizhou, Zhejiang, there is a region with high terrain in the east and low in the west. The mold industry is developed and is known as the hometown of molds. An enterprise Taizhou Huangyan Anye Industry and Trade Co., Ltd. stands in Huangyan, where high-tech development is fast. The company is China Household Injection Mould Suppliers and Custom Household Injection Mould Company, which has a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development.

1. 20 years of mold manufacturing experience Specializing in the design and manufacture of large and medium-sized injection molds, with a certain level of research and manufacturing for car lamp molds, automotive interior parts molds and other plastic molds, and timely delivery to provide domestic and foreign customers with high-quality and competitive mold products

2. Strict quality control Aiming at the various checks in the mold manufacturing process, the company has established a complete CAD/CAM and CAE system to realize the integration process of reverse modeling, runner analysis, and mold design. The company's mold structure is reasonable, with high dimensional accuracy, good molding performance and long life.

3. Advanced processing equipment With strong production strength and fast delivery, we have advanced processing equipment such as CNC and EDM. The mold products cover injection molds for automobiles, motorcycles, home appliances, daily necessities, etc., tailored to customer requirements and product characteristics! ! !

4. A good after-sales service Customer trust is our value. Mold products have a long-term after-sales warranty period to ensure that customers have no worries after-sales, quickly analyze the reasons, and quickly assign a dedicated person to the site quickly

Latest News

-

Car Light

Various traffic lights installed on cars to ensure safe driving. There are two types of lights and signal lights. From 1905 to 1912, in order to solve... -

What are the advantages of injection molding parts for automobiles

Injection molding is a method of producing shapes for industrial products. Products usually use rubber injection molding and plastic injection molding... -

Analysis of Current Situation of Automobile Lamp Industry

Analysis of Current Situation of Automobile Lamp Industry From a worldwide perspective, automobile lamp manufacturers are closely connected with vehic... -

The Basics of Motorcycle Parts Injection Mold

The Basics of Motorcycle Parts Injection Mold Injection molding is a widely used manufacturing process that involves the production of complex shapes ...

English

English 中文简体

中文简体