Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

You will probably see that injection molding is the best choice for home appliance parts. When you look at things like kitchen gadgets or washing machines, you notice injection molding is used a lot. This process gives very exact results, so each part fits just right. Injection molding helps make many parts quickly for Commodity appliances. It is fast and saves money. The method lets you make hard shapes and strong parts. Many brands use injection molding for making home appliances because it gives close measurements, can be repeated, and offers many material choices.Injection molding in home appliance making means you get strong, good parts every time.

Injection molding makes strong and exact parts. These parts fit well and last a long time in home appliances.

Careful quality checks and good mold design keep each part the same. This also helps stop mistakes or broken parts.

This way of making things is fast and saves money. It also uses less material and energy.

Injection molding lets you make many different shapes. You can also pick colors and finishes you like.

The first cost is high, but you save money with big orders. The molds can be used many times, even hundreds of thousands of times.

Every part in your home appliances should fit well. Precision injection molding helps you get exact sizes and shapes. This means parts for washing machines and other appliances work together easily. ABS and PP thermoplastics are important in this process:

ABS needs smooth molds for a shiny look and exact size. You find ABS in parts that need to look good and fit well.

PP is good for making lots of parts fast. It fills molds quickly and cools fast, but it shrinks more than ABS. Careful mold design and cooling keep the right shape and size.

ABS is best for exact fit and nice surfaces. PP works better for flexible designs and saving money.

Mold flow analysis shows how melted plastic moves inside the mold. It helps you find problems like warping or air bubbles before making parts. You can change the mold design to get better results. GUANGCHAO uses these steps to make sure their parts are very precise.

All parts should look and work the same. Consistency in injection molding comes from strong quality checks. Makers check raw materials, keep molds working well, and watch the process closely. Here is how they do it:

| Quality Control Process | Description and Purpose |

|---|---|

| Raw Material Inspection | Checks plastic quality to keep parts uniform. |

| Mold Design and Maintenance | Keeps molds working right for every cycle. |

| Process Optimization | Adjusts temperature and pressure to avoid defects. |

| In-Process Inspection | Uses sensors and cameras to catch mistakes fast. |

| Dimensional and Visual Inspection | Measures and checks parts after molding to make sure they look and fit right. |

| Quality Documentation and Traceability | Tracks everything for quick fixes and clear records. |

You see these steps in factories that make home appliances. Even small problems can cause big trouble, so companies like GUANGCHAO use strict checks to keep every part working well.

Durability is important for home appliance parts. You want parts that last for years. Precision injection molding makes strong and reliable parts. Mold flow analysis helps you design molds without weak spots. You can add ribs or change wall thickness to make parts tougher.

Makers use new molding methods and materials to make parts last longer. Insert molding adds metal pieces for extra strength. Industry 4.0 tools, like sensors and robots, help find problems early and keep machines working well. Eco-friendly plastics and energy-saving machines help the environment.

Common problems like warping, cracking, or sink marks can make parts weak. You can fix these by changing mold temperature, pressure, and cooling time. Here is a quick look at some problems and how to fix them:

| Defect | Common Causes | Mitigation Strategies |

|---|---|---|

| Warping | Short cycle time, poor cooling, thin walls | Increase cooling time, improve mold design, adjust wall thickness |

| Sink Marks | Low injection pressure, small gate, poor gate position | Raise pressure, change gate size and location |

| Cracking | Cold mold surface, slow injection speed | Warm up mold, speed up injection |

Rules like ISO 9001 and UL make sure your parts are safe and good quality. These rules are used from picking materials to checking finished parts.

Tip: If you choose precision injection molding for home appliances, you get parts that fit well, last long, and look nice. Companies like GUANGCHAO work hard to keep quality high.

You need to make many appliances fast. Injection molding helps you do this. It uses high pressure to fill molds quickly. This makes the process very fast. You can make hundreds of parts each day. Multi-cavity molds make more than one part at a time. You spend less time waiting for parts. More appliances get ready for sale faster.

Tip: Fast production lets you meet customer needs and grow your business.

Plastic injection molding saves money in many ways. Making lots of parts spreads mold cost over each item. This lowers the price for every part. Automation means machines do most of the work. You need fewer workers. Modern machines use less energy. They cut electricity use by up to 70%. You can recycle leftover plastic. This saves money on new materials. Smart design makes parts easier to mold. You avoid extra steps and costs.

Here are ways injection molding saves money:

Fast, automated production lowers cost for each part.

Using recycled materials cuts raw material costs.

Good quality control means fewer mistakes and less waste.

Quick production lowers storage and inventory costs.

Plastic injection molding uses materials very well. The process puts just enough plastic in each mold. You do not need to cut away extra material. This means less waste and more savings. You can mix recycled plastic with new plastic. This helps the planet and saves money. Other molding methods waste more material. Injection molding has smaller sprues and no overflow channels. It is great for making many appliance parts with thin walls and hard shapes.

Note: Using materials well helps the earth and keeps costs low.

Injection molding lets you make parts with hard shapes. You can design appliance parts with small details and tight fits. You can add curves, undercuts, and special features. Other methods cannot do this as well. Some parts need clips or hollow spaces. These are used in things like fridges or vacuums. Injection molding makes these shapes in one step. High-pressure machines help make parts with many uses. Handles can have buttons built in.

Tip: You can save time by making all features in one step.

Injection molding lets you change how your parts look and feel. You can pick shapes, colors, and textures. Here are some choices you have:

You can add colors, patterns, or logos while molding. This helps your appliances match your style or brand.

Insert molding mixes metal and plastic in one part. This makes knobs or handles stronger and special.

You can choose from finishes like matte, glossy, or clear.

Molding lets you add small things like buttons or grips. These make your appliances look and work better.

You can put your logo on each part so it stays clear.

Rapid prototyping helps you test new ideas fast before making many parts.

GUANGCHAO uses these choices to help you make appliances that stand out.

Note: Customizing with injection molding helps your appliances fit your needs and style.

You have many ways to make your appliance parts look nice. Injection molding gives finishes that look good and last long. You can use spray paint for bright colors. Powder coating makes surfaces tough. UV coating stops scratches. Laser etching adds marks or logos. In-mold labeling puts graphics inside the part so they last. Chrome plating gives a shiny look without adding weight.

Here is a table that shows common finishes for appliance parts:

| Surface Finish Type | Description | Typical Use in Home Appliances | Material Compatibility |

|---|---|---|---|

| Glossy | Shiny and modern look | Used with ABS for a fancy look | ABS plastic |

| Semi-glossy | Not too shiny, hides fingerprints | Used in many appliances | ABS and similar plastics |

| Matte | Not shiny, hides marks | Used to cut glare, strong finish | Polypropylene |

| Textured | Gives grip and rough feel | Used for parts that need grip | Polypropylene |

You can pick the finish that matches your appliance. Injection molding helps you get the look you want and keeps parts strong.

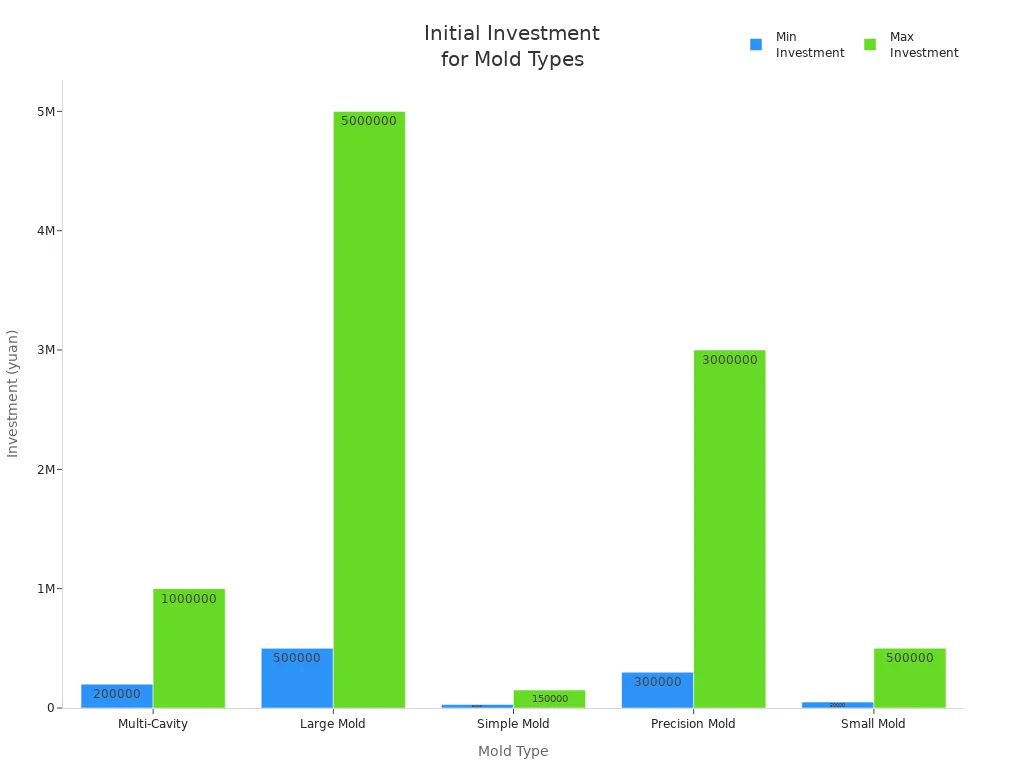

If you pick injection molding, you must spend a lot at first. You need to buy machines and molds. The machines can cost $50,000 or even more. You also have to pay skilled workers to use and fix them. Mold prices change based on size and shape. Here is a table that shows how much different molds cost:

| Mold Type | Initial Investment Range (yuan) | Application in Home Appliance Manufacturing |

|---|---|---|

| Multi-Cavity | 200,000 - 1,000,000 | Large batch production molds (e.g., bottle caps) |

| Large Mold | 500,000 - 5,000,000 | Large components for home appliances |

| Simple Mold | 30,000 - 150,000 | Trial molds for appliance prototypes |

| Precision Mold | 300,000 - 3,000,000 | High precision parts (less common in appliances) |

| Small Mold | 50,000 - 500,000 | Electronic components, possibly appliance controls |

You can see that some molds cost millions of yuan. This makes injection molding expensive at the start. But it is worth it if you need to make many parts.

There are other ways to make appliance parts. 3D printing and CNC machining are good for small jobs. These ways cost less for tools and are faster to start. You can change designs quickly with them. But if you need many parts, they cost more for each one. Vacuum forming is another choice. It is cheaper and faster to set up. But it cannot make strong or detailed parts like injection molding. If you need lots of parts, injection molding saves money. The break-even point is between 250 and 2,000 parts. After that, injection molding is cheaper for each part.

You want your molds to last a long time. Taking care of them helps you get more use. Here are some good tips:

Clean molds after each use and look for damage.

Add oil to molds so they do not wear out.

Check for cracks or chips and fix them soon.

Write down when you clean or fix molds.

Use new repair tools like laser welding for cracks.

Teach workers to use molds right and spot problems early.

Some companies use new coatings to help molds last longer. For expensive molds, you can use smart sensors to watch their condition. This helps stop breakdowns and keeps work going. With good care, molds can last for hundreds of thousands of uses. This makes injection molding a good choice for making many parts.

Tip: Take care of your molds and fix them fast. This saves money and keeps your factory running.

Injection molding makes parts that fit well and last long. It also saves money when making home appliances. You can pick materials like ABS or PPO. These materials help make strong and safe parts. GUANGCHAO uses smart mold designs and checks for quality. This helps stop problems before they happen. If you need lots of parts with hard shapes, injection molding works best.

Decide what look and design you want first.

Choose makers who know a lot and can help you.

Watch things like heat and pressure to get good parts.

Tip: Plan ahead and ask experts for help to make your injection molding project work well.

ABS and polypropylene work well for most appliance parts. You get strong, safe, and good-looking results. GUANGCHAO uses these materials to make reliable products.

You can use a well-maintained mold to make hundreds of thousands of parts. Regular cleaning and checks help your mold last longer.

Yes, you can pick many colors and finishes. You choose glossy, matte, or textured surfaces. You can add logos or patterns during molding.

Injection molding works best for large batches. You save money and get strong parts. 3D printing suits small runs or prototypes.