Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

You can see many types of automotive moulds in cars. Some types are injection, compression, blow molding, vacuum forming, and low foaming plastic molds. Each type uses a special way to shape car parts. Injection molding makes dashboards, door panels, and bumpers. Blow molding makes hollow parts like fuel tanks. Vacuum forming works well for detailed parts. Low foaming molds help make light items. These moulds are important in making cars. They shape many car parts for different jobs.

Automotive moulds help shape car parts in many ways. They use methods like injection, compression, and blow molding. Injection moulds make detailed parts fast, like dashboards and bumpers. Compression moulds make strong and light parts. They do not waste much material, so they save money. Blow molding is good for hollow parts like fuel tanks. These parts are strong and not heavy. Vacuum forming makes big and detailed parts quickly. It is good for custom designs. Low foaming plastic moulds make parts lighter and softer. This helps cars feel comfy and use less fuel. Picking the right mould is very important for good car parts. Knowing about automotive moulds helps makers create new things. It also helps them follow safety and environmental rules.

Automotive moulds help make car parts. You can sort these moulds by how they use materials. Some moulds work with thermoplastics. Others use thermosetting plastics. This sorting helps you know which mould is right for each job. Every type has its own way and use.

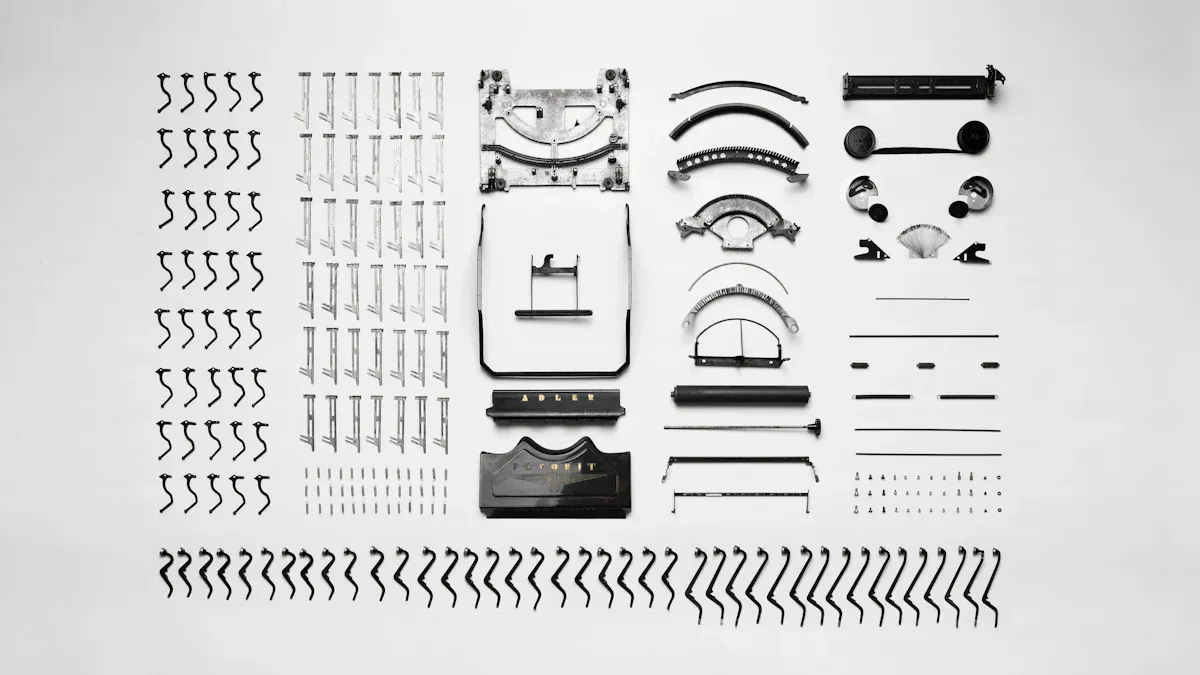

There are a few main types of automotive moulds. Each one shapes parts in its own way. Here is a table with the most common types and what they do:

Type of Mould | Description |

|---|---|

Stamping Moulds | Used to shape car body parts by stamping. |

Injection Moulds | Heats plastic and puts it into a mould, good for tricky shapes. |

Compression Moulds | Adds plastic to an open mould, best for thermosetting plastics. |

Transfer Moulds | Pushes plastic in a heated chamber, shapes detailed parts. |

Extrusion Moulds | Makes plastics with the same shape, like pipes and sheets. |

Each mould type shapes materials in a special way. Injection moulds are good for thermoplastics and make tricky shapes. Compression moulds work with thermosetting plastics and make strong parts. Transfer moulds also use thermosetting plastics and make detailed shapes. Extrusion moulds make long, hollow things like tubes.

When you look at molding types, each one has its own benefits. Here is a list that explains some common molding types:

Horizontal molding is good for big moulds and lots of parts. You get even parts and quick results.

Vertical molding is best for careful jobs. You can use it for custom parts and careful insert work.

Compression molding takes more time but makes strong, thick parts. It works for medium and big pieces.

Extrusion molding makes long, hollow shapes. You can make pipes and sheets for many things.

Injection molding (hot runner) is quick and saves money. You can make many small or medium parts fast.

Cold runner injection molding is good for lots of parts. You get short wait times and can make tiny pieces.

Rotational molding is slower but makes big hollow things. It saves money for some jobs.

Transfer molding pushes rubber into the mould with a piston. You can shape parts for special needs.

The molding type you pick depends on the part and material. Each way gives you different speed, strength, and shape.

Tip: Knowing about molding and automotive moulds helps you choose the best way for each car part.

Guangchao Mould

Injection molds are very important in making cars. These molds help make car parts fast and with great detail. You can use them to shape easy or hard parts. This way, you get good quality and the same results each time.

The steps for automotive injection molding are easy to follow. Here is how it works:

Material Selection: Pick the right material for each part.

Material Preparation: Melt and mix the material well.

Injection: Push the melted material into the mold with high pressure.

Cooling: Let the part cool and get hard inside the mold.

Ejection: Take the finished part out of the mold.

Trimming and Finishing: Cut off extra bits and make the surface smooth.

Quality Control: Check the part at every step.

Regrinding and Recycling: Use leftover material again.

This process helps you make car parts that are strong and have lots of detail.

You can pick from many materials for automotive injection molds. Each one has special uses and features. Here is a table to show you the choices:

Material | Properties | Applications |

|---|---|---|

PE | Works well for fuel tanks and air ducts. | Fuel tank, air duct, seat cover |

PVC | Cheap, easy to use, soft or hard. | Dashboard skin, steering wheel, flooring |

PS | Clear, breaks easily, can be made stronger. | Instrument shells, lampshades |

ABS | Easy to finish, not expensive, stands up to weather. | Decorative strips, handles, mirrors |

PA | Takes in water, not very steady. | Hoses, filters, water pump housings |

PMMA | Very clear, does not age fast. | Lighting signs, door glass |

POM | Very strong, like steel but plastic. | Many automotive components |

PC | Tough, can be mixed with glass fiber. | Lampshades, bumpers, panels |

PU | Can be hard or soft, takes in shakes. | Seat cushions, steering wheels |

You choose the best material for what the part needs to do.

Injection molds help make many car parts. Some common uses are:

Dashboards

Door panels

Clips

Fasteners

Bumpers

Headlights

Hose fittings

Door handles

Dashboard buttons and switches

This molding lets you make inside and outside car parts. The parts are strong, light, and look nice. Using plastic makes cars lighter, so they use less fuel and work better.

Injection molds are different from other automotive molds. You can make parts in many shapes and sizes. This helps you design new and better car parts. You can also make very tricky parts that look good and work well. The process is fast and saves money when making lots of parts. When you make more, each part costs less. This is good for making cars. You also keep the quality high for every batch.

Tip: Injection molding helps you make strong, detailed, and nice-looking car parts in large numbers.

You can use different injection molds for different car parts. Here are some main types and what they do:

Interior Components: Dashboards, panels, vents, cup holders, and knobs. These are made to look and feel good.

Exterior Components: Bumpers, fenders, grilles, and light housings. These are made to be tough and last outside.

Functional Components: Engine covers, fluid reservoirs, and connectors. These need to handle heat, shaking, and chemicals.

Specialty Elements: Clips, fasteners, and gaskets. These help put the car together and keep it working well.

Pick the right injection mold for each part’s job and quality needs. The right automotive injection mold makes sure your car parts are safe, strong, and look good.

Guangchao Mould

Compression moulds are important in making cars. You use them for strong and light parts. They are good for big pieces. Compression molding does not use runners or gates. This means you waste less material. It helps save money when making car parts.

Compression molding has easy steps to follow. First, you heat the material. Heating helps it flow and fill the mold. Next, you put the hot material in the open mold. Then, you close the mold and press down. The material spreads and takes the mold’s shape. Sometimes, you press at room temperature. You may also mix in extra things.

This way, you can make thick and strong parts.

You can pick from many materials for compression molds. Each one gives the part special features. Some common choices are:

Bulk molding compound (BMC)

Sheet molding compounds (SMC)

Carbon fiber

Epoxy resin

Glass fibers

High-density polyethylene (HDPE)

Polyurethane (PU)

Phenolic molding compound

Silicone rubber

Polyamide-imides (PAIs)

Polyether ether ketone (PEEK)

Polyphenylene sulfide (PPS)

Polytetrafluoroethylene (PTFE)

Urea-formaldehyde (UF)

Urethane

Diallyl phthalate (DAP)

Melamine

Nylon

The material you choose changes how the part fills the mold. It also affects how fast it heats and cools. Some materials need more pressure to fill the mold. If a material cools slowly, it takes longer to finish. This can change how the part turns out.

Compression molds help make many car parts. They are great for light pieces. Light parts help cars use less fuel. Some common uses are:

Bumpers

Door panels

Dashboards

O-rings

Dampening boots

Vibration-resistant components

Compression molding is used for big flat or curved parts. You see it in hoods, fenders, scoops, and spoilers. It also works for small and detailed pieces.

You find it in seat backs, head rests, airbag housings, B pillars, door beams, bumper beams, and big floor parts.

Compression molds have many good points for making cars:

You save money because you use less material.

You can make big parts without worrying about weight.

You do not need gates or runners, so you use less material.

Parts look better because there are fewer marks.

You can make parts in many sizes, only limited by the press.

Compression molding is different from injection molding. It works well for big and strong parts. You can use it for simple or tricky shapes. This makes it a smart choice for car molds.

Guangchao Mould

Blow molding is a way to make hollow car parts. You see this method in many car molds. It shapes pieces that are light and strong. Blow molding is different from injection molding. You blow up a plastic tube inside a mold. The tube fills the mold’s shape. This works best for hollow and tough parts.

Blow molding makes hollow parts. You blow air into a soft plastic tube. The tube fills the mold and takes its shape.

Here are the steps for blow molding:

Heat a plastic tube until it gets soft.

Put the tube inside the car mold.

Blow air into the tube so it gets bigger.

The tube touches the mold walls and cools down.

Take out the finished part and cut off extra bits.

Blow molding makes hollow parts by blowing up a tube. Injection molding pushes melted plastic into a mold. Blow molding is better for light car parts.

You can pick from many materials for blow molding. Each one has good points. Here is a table to show the differences:

Material | Advantages |

|---|---|

HDPE | Easy to mold, see-through, colors well, safe, recycled a lot. |

PP | Stiffer than HDPE, good for hot jobs, easy to mold, see-through, colors well. |

PVC | Can be hard or soft, used in many ways, some worry about chemicals. |

PET | Used for clear containers, easy to recycle. |

TPE | Not see-through, colors well, used in cars, molds well after drying. |

Pick the material that fits the part and process.

Blow molding is used for many car parts. It works best for hollow and light pieces. Here are some common uses:

Fuel tanks

Air ducts

Fluid reservoirs

Wheel covers

Washer tanks

Inside trim parts

Air intake parts

HVAC ducts

Fluid pipes and tubes

This process also makes special car parts. Here is a table with more examples:

Car Part Type | Description |

|---|---|

Air Intake Duct | Ducts with metal fasteners, used for air in cars. |

Automotive Ducts and Tubes | Systems for water and air, made with one or two walls. |

Reservoirs and Tanks | Tanks made to fit odd spaces, with different caps and features. |

Panels, Boots, and Covers | Tough panels and flexible parts that protect people and let parts move. |

Blow molding has many good points for car molds. You get lighter and stronger fuel tanks. The smooth design helps stop leaks and keeps cars safe. You can make tricky shapes for air ducts. These fit well and help engines work better. Blow molding makes comfy seats that keep people safe. You also make good HVAC parts that move air and work with other car systems.

You make hollow parts fast and easy.

You save weight, so cars use less gas.

You shape parts with curves and details.

You lower leaks in tanks and reservoirs.

You make seats and trim that are comfy and safe.

Blow molding is important for car molds. You use it for many car parts that need to be light, strong, and hollow.

Guangchao Mould

Vacuum forming is an easy way to shape plastic sheets. You use it to make car parts that are big, light, and have lots of detail. Many car molds use vacuum forming because it works for small and large batches. This method is good when injection molding costs too much or takes too long.

You follow a few steps to use vacuum forming for cars. First, heat a thermoplastic sheet until it gets soft. Next, put the warm sheet over the mold quickly. Then, make a vacuum to pull the sheet tight around the mold. This step gives you smooth shapes and clean edges. Cool the plastic so it gets hard and keeps its shape. Last, trim off extra plastic to finish the part.

This way, you get parts with neat edges and good details. You can use these steps for many car molds.

You can choose from many materials for vacuum forming. Each one has its own benefits for car molds. Here is a table to help you compare:

Material | Key Properties | Common Applications |

|---|---|---|

ABS | Tough, does not break easily, handles heat well | Car parts, covers for electronics |

PVC | Cheap, resists chemicals, stands up to weather | Packaging, signs, building materials |

Polycarbonate | Very strong, resists heat and impact | Car lights, airplane parts, medical tools |

HDPE | Strong, resists chemicals, lightweight | Containers, tanks, trays |

PETG | Clear, tough, easy to shape | Displays, medical packaging, signs |

HIPS | Strong, keeps its shape | Packaging, car parts |

Pick the material that fits what the part needs to do. For example, use ABS for dashboard panels because it is tough and looks nice.

Vacuum forming helps you make many car parts. You use it for inside and outside pieces. Here is a table that shows common uses:

Application Type | Parts Produced |

|---|---|

Interior | Dashboard panels, door panels, trim, consoles |

Exterior | Many outside car parts |

Use vacuum forming to make panels, covers, and trim. These parts are light, strong, and look good. You also use vacuum forming for custom parts in special cars.

Vacuum forming has many good points for making car molds. You can see these features in the table below:

Feature | Description |

|---|---|

Versatility | You use vacuum forming for many car parts and other things. |

Material Standards | You use thermoplastics that are safe and strong. |

Cost-Effectiveness | You spend less money and get parts faster than with injection molding. |

Scalability | You can make a few parts or thousands, whatever you need. |

Design Flexibility | You make tricky shapes and new designs for cars. |

Quality Assurance | You test parts for strength, heat, and impact to make sure they last. |

Environmental Impact | You use materials that can be recycled and make less waste. |

Tip: Vacuum forming helps you try new designs and make parts fast. You save money and help the planet by using recyclable materials.

You see vacuum forming used for dashboards, trim, and covers. This way helps you make parts that look good and last a long time. You get more choices for shapes and finishes than with other molds.

Guangchao Mould

Low foaming plastic moulds help make car parts light. These parts have a special feel. You use these moulds for strong but not heavy pieces. This way is not the same as injection molding. You add a foaming agent to the plastic. The agent makes tiny bubbles inside the part. These bubbles make the part weigh less. The part also feels softer.

First, pick the right plastic and foaming agent. Mix them together and heat the mix. The foaming agent lets out gas when hot. The gas makes small bubbles in the melted plastic. Put the mix into the automotive mould. The bubbles stay inside as the plastic cools. The plastic gets hard and keeps the bubbles. Take the part out of the mould. The part is lighter and softer than solid plastic.

You can pick from many materials for low foaming plastic moulds. Each one helps car parts in a special way. Polypropylene is good because it does not get wet or damaged by chemicals. It is safe and not heavy. You use it for outside parts like fenders and bumpers. Acrylonitrile butadiene styrene (ABS) is tough and does not break easily. You can make tricky shapes like dashboards and door panels. Polyamide is strong and light. It does not wear out, rust, or get hurt by chemicals or heat. Polyurethane is tough and can be used in many ways.

Here is a table with the main materials and their good points:

Material | Benefits |

|---|---|

Polypropylene (PP) | Does not get wet or damaged by chemicals, light, helps cars use less gas. |

Polyurethane (PU) | Tough and can be used in many ways. |

Polyamide (PA) | Strong, light, does not wear out or rust, safe from chemicals and heat. |

Acrylonitrile Butadiene Styrene (ABS) | Light, tough, does not break, easy to shape, safe from rust and heat. |

You can also see the main materials and what they do in this list:

Polypropylene (PP): Good for many uses, does not get wet, light, safe from heat.

Acrylonitrile Butadiene Styrene (ABS): Light, tough, does not break, easy to shape, safe from rust.

Polyamide (PA): Strong, light, does not wear out, safe from chemicals and heat.

Polyurethane (PU): Tough and can be used in many ways.

You use low foaming plastic moulds for lots of car parts. These parts need to be light and tough. You see them in dashboards, door panels, seat cushions, and trim. You also use them for bumpers, fenders, and grilles. The foaming makes parts that take in shocks and lower noise. This helps make cars safer and more comfy. Lighter parts also help cars use less gas.

Low foaming plastic moulds give you many good things:

You make parts lighter, so cars use less gas.

You make pieces that take in shakes and noise.

You use less plastic, so you save money.

You can shape tricky parts with soft surfaces.

You help drivers and passengers feel safe and comfy.

Tip: Low foaming plastic moulds help you make car parts that are light, tough, and comfy. You can use them for many car jobs.

Guangchao Mould

Some automotive moulds do special jobs in making cars. These specialized moulds help make parts with special shapes or needs. Transfer molding is a key process for these jobs. You use transfer molding to make seals, gaskets, and dashboards. This method makes parts that keep their shape and last in bad weather. These things are important so your car works well for a long time.

Here are some things specialized automotive moulds can do:

They make strong parts that need to last.

They help meet tough rules for seals and gaskets.

They make dashboards that do not change in heat or cold.

They make parts that keep out rain and dust.

Specialized moulds are not as common as injection molding. But you need them for parts that must work in hard places.

Note: Specialized automotive moulds fix problems that regular moulds cannot. You use them when you need extra strength or special shapes.

You also see automotive moulds used for special jobs. These moulds help make parts for certain needs in cars. The market for chassis moulds has two groups: OEMs and the aftermarket. OEMs work with mould makers to make new car parts. You count on OEMs for the first car frames and other big parts. The aftermarket makes parts for fixing or changing cars. More people want these moulds as they keep cars longer or want a new look.

New car designs mean you need more special moulds. Electric and hybrid cars need new frames and battery packs. You need moulds that can make these new parts. The aftermarket grows as drivers want new or custom parts. This means you need more special moulds for different jobs.

You also see new trends in automotive moulds:

Safety rules mean you need strong chassis moulds.

Light materials like carbon fiber and aluminum need new mould ideas.

Emission rules make you change chassis designs with new moulds.

These special uses show how automotive moulds change with the car industry. You use them to meet safety, design, and green rules.

Tip: When you pick automotive moulds for special jobs, you help your car stay safe, work well, and use new technology.

Guangchao Mould

You can find many kinds of automotive molds in making cars. Each mold type, like injection, compression, transfer, and extrusion, shapes car parts for special uses. The table below shows what each mold does and what it makes:

Type of Mould | Description | Primary Use in Car Manufacturing |

|---|---|---|

Injection Mold | Uses hot plastic that gets pushed into a mold. | Makes tricky plastic parts fast and easy. |

Compression Mold | Adds plastic to an open mold and heats it up. | Good for thermosetting plastics, like electric shells. |

Transfer Mold | Melts plastic in a hot chamber and moves it to the mold. | Makes detailed shapes, mostly for thermosetting plastics. |

Extrusion Mold | Makes plastic with the same shape over and over. | Used for things like pipes and sheets. |

If you know how to pick the right mold, you help make better car parts. You make work faster, save money, and keep parts good. Picking the best injection molding way helps you make strong and detailed pieces. You also see how each injection process brings new ideas to car design.

When you learn about automotive molds, you see the skill and smart ideas in every car. You notice how engineers use injection and other ways to fix problems and make cars safer and lighter.

Guangchao Mould

Automotive moulds help you shape car parts. You use them to make parts that fit together well and last a long time. Each mould type gives you different shapes and features.

You should use low foaming plastic moulds. These moulds help you make parts that weigh less and absorb shocks. Lighter parts help your car use less fuel.

Yes, you can recycle many plastics used in automotive moulds. You help the environment by reusing leftover materials. Some moulding processes let you use recycled plastics for new parts.

You look at the part’s size, shape, and job. You pick a mould that matches the material and design. Injection moulds work for detailed parts. Compression moulds suit big, strong pieces.

Injection moulds push melted plastic into a closed shape. Compression moulds press heated material in an open shape. You use injection for tricky details. You use compression for thick, strong parts.

Yes, you use automotive moulds for electric vehicles. You make battery covers, lightweight frames, and special trim. New moulds help you meet safety and design needs for electric cars.

Car makers use vacuum forming to shape large plastic sheets. You get smooth, detailed parts quickly. This method works well for dashboards, panels, and custom trim.

Tip: You can ask your mould supplier for advice on picking the best mould for your project.

Guangchao Mould