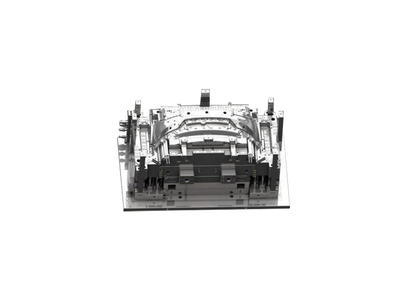

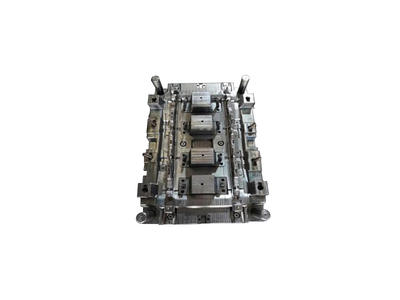

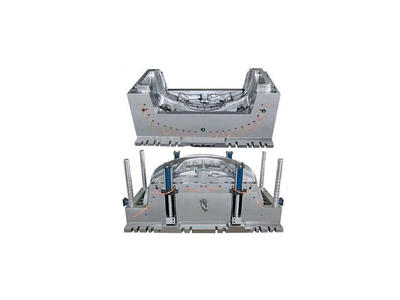

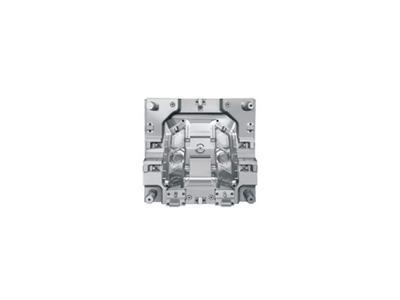

Motorcycle Headlamp Housing Plastic Injection Mould

Product Name: Motorcycle Headlamp Housing Plastic Injection Mould

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Mould material: P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc.

Mould Type: Injection Mould

Product material: ABS, PA, PA66+GF, POM, PC, PP, PET, TPE, PVC, HDPE, etc.

Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Die tooling equipment: lathe, milling, grinding machine, drilling machine, CNC, EDM, wire cutting machine, punching machine

Maximum mold size: 1500*1500 mm

Gate: side gate, auxiliary gate, straight gate, hook gate, pin gate, etc.

Cavities: single or multiple cavities

Surface finish: chrome, silk screen, textured, painted

Mold life: 45#: 300,000 to 500,000 times

Injection molding machine production capacity: 0.1g~6000

P20: 600000 times

718:800000 times

Lead time: about 3-4 weeks

Packing: wooden box or as customer's request

Details

What can we do for you?

1. We are a professional plastic manufacturing factory, design different plastic molds, we provide products from small PC to large PC

2Professional controllable injection molding process

3. Injection products of different plastic materials, different colors and different shapes

4. If you have any new items to make, please contact us. We can do our best to turn your idea into a real product.

5. We can do color according to your requirements, we specialize in high performance polymer processing

Supply capacity

200 sets/year

Packaging and Delivery

Packaging details: professional headlight injection molding, sponge + plastic bag + wooden box

Port: Ningbo

Detailed process

1. Tell us your idea or send samples, we can draw.

2. Quote according to drawings and other important details.

Regarding quotes, in addition to 2D and 3D graphics, details like the material you choose, what color you need, how much quantity you need, etc. are very important!

3. Make the mold after all details are confirmed.

4. Make a sample for you to check if there are any parts that need to be replaced, we can modify the mold.

FAQ

Q: What is the lead time for plastic injection molds?

A: Short delivery time: 35-50 working days.

Q: How do I know the plastic mold or tool you are producing is correct?

A: We can provide free prototypes and then make molds.

Q. How do you deal with wrong molds?

A: We can help correct bad mold designs.

Q: What if the plastic product is different from the sample?

A: If the goods you receive are not the same as the samples, we accept the refunded goods, and all shipping costs from our side, and we will also refund all the money to your account.

Q: What happens if we receive substandard PVC/PE/PP/PS/ABS products?

A: If you find that there are some products with poor quality, then we will accept to send high-quality products to you again.

Q: What if we have transportation difficulties when delivering custom plastic molds?

A: If you have some shipping problems, we can help you solve them at the first time.

Q: How soon can we receive quotations for injection moulds?

A. Your inquiries about our products or prices will be answered in a timely manner

Q: What about your plastic injection mold team?

A: Well-trained and experienced staff who can answer all your queries in fluent English

Feature

1. We are a professional manufacturer of OEM injection molded parts, from design to rapid prototype to mold to mass production for more than 20 years.

2-Material: Various plastics such as ABS, PC+ABS, acrylic, PVC, TPE, PBT-PC, PEPP, PPS, PA, PEI, POM and all other engineering plastics with or without additives.

3- Provide customers with important size samples and customized inspection report material certification for verification and verification.

4- Standard dimensions are controlled according to the intermediate tolerances specified by ISO and DIN.

5- We can use a variety of graphic formats: Pro/E Solid Works, Cimatron AutoCAD, etc.

6 sets of equipment including CNC, EDM, grinder, injection molding machine (from 45 tons to 1000 tons), we can provide high precision and complex injection molds and products

7- We provide unique solutions for your products with reasonable price, good quality and best service.

We accept small batch orders and look forward to receiving your inquiry.

Hot Tags: Motorcycle Headlight Housing Injection Mould, China, Manufacturers, Suppliers, Factory, Customized, Low Price, Buy Discount, Free Sample, Made In China, Motorcycle Taillight LED, Car Headlight LED Mould, Toilet Seat Cover Mould, Cultural plastic float, Y-shaped pipe fitting mould, beer box mould

(For more details, please feel free to contact us.)

Medical laboratory product injection molding is a process used to manufacture plastic parts and components for use in a medical laboratory setting. In this process, melted plastic material is injected into a mold cavity, where it cools and solidifies into the desired shape. Injection molding is a cost-effective method for mass-producing plastic parts and is often used for producing components such as pipettes, test tubes, and other laboratory supplies. Injection molds can be made to produce parts with very precise dimensions and can be used to create complex shapes and features. The medical laboratory industry relies on injection molding to produce high-quality, accurate, and reliable products that are essential for conducting experiments and analyzing results.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Motorcycle Headlamp Housing Plastic Injection Mould Manufacturers and Wholesale Motorcycle Headlamp Housing Plastic Injection Mould Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

OEM Household plastic chair mould making dining Office plastic armless chair molding

-

Outdoor Waste Sorting Box Plastic Injection Mould

-

Environmentally Friendly Plastic Cup Injection Mould

-

Motorcycle Tail Light Mould

-

Motorcycle Headlamp Housing Plastic Injection Mould

-

Car Bumper Bracket Plastic Injection Mould

-

Automotive Led Front Fog Lamp Parts Plastic Molds

-

Car Front Bumper Injection Mould

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Auto Headlight Plastic Injection Mold

-

Auto Precision Sensor Injection Mold

-

Medical Laboratory Plastic Petri Dish Injection Mold

English

English 中文简体

中文简体