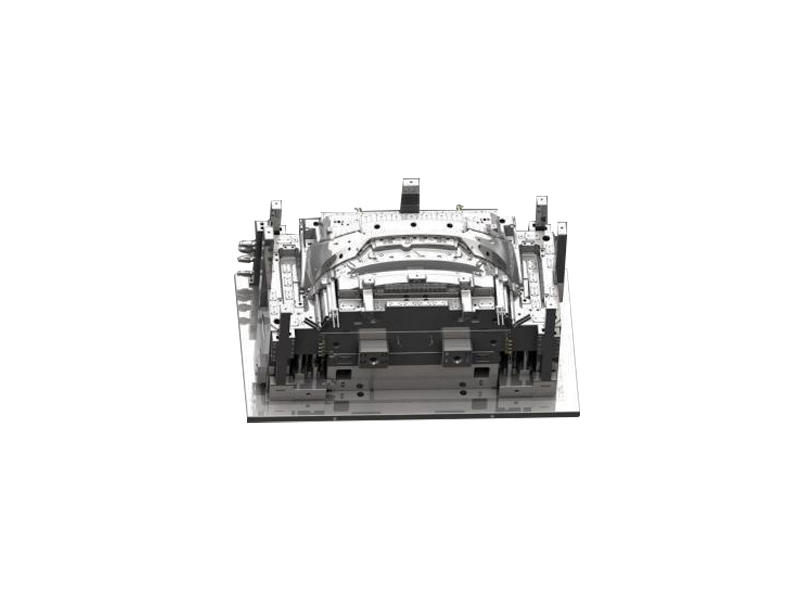

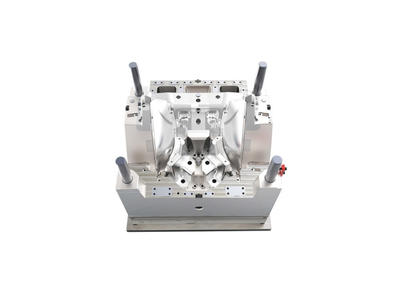

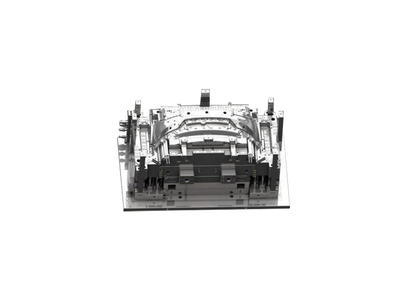

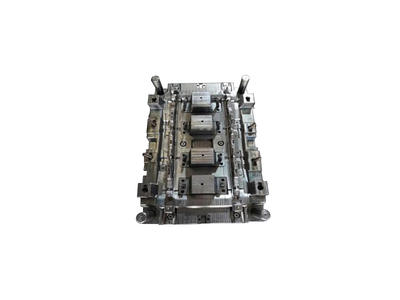

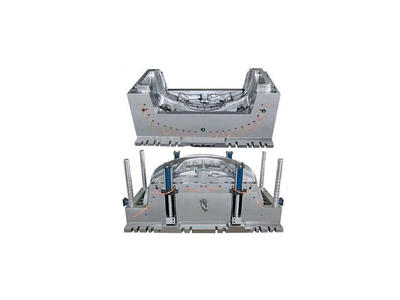

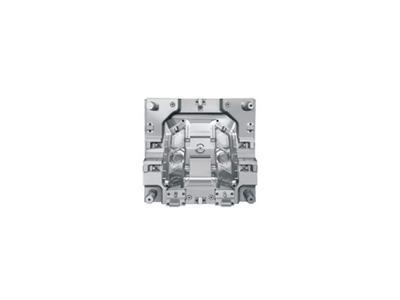

Car Bumper Bracket Plastic Injection Mould

Product Name: Car Bumper Bracket Plastic Injection Mould

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Die steel: P20/718/738/NAK80/S136/2738/2316

Molding mode: plastic injection molding

Mold Cavities: Custom Cavities

Processing equipment CNC milling, engraving, etc.

Product Type: Auto Parts

Design software: UGNX CAD

Delivery time: Delivery time is about 30-170 days after payment, depending on mold complexity and shipment date

Packing: auto parts wooden box mould auto parts

Available places: Nationwide

Certificate: ISO9001

Payment method: Sight Letter of Credit, telegraphic transfer (L/C at sight,T/T)

Finished product: Please tell us the quantity you want, then we will quote you as soon as possible.

⇒ Our company produces high quality SMC molds and plastic injection molds, such as car bumpers, face shield grilles, hoods, pedals, truck wind deflectors, car air filters, etc.

⇒We can produce molds according to your samples or technical drawings. If you need finished products, if you want large quantities, we can produce them.

Details

Supply capacity

200 sets/year

Production Process

We have strong design technology to make better 3D design, and in the production process, we use excellent CNC technology to ensure the quality of the mold. After you buy our molds, we can provide you with timely after-sales service and professional after-sales service. Besides, moulds can be produced according to your samples or technical drawings.

We warmly welcome our customers to visit us and work together to create a better future!

Packaging and Shipping

Packaging Details:

The wooden box is a professional injection mold manufacturer, which is used for forming the rear bumper of the car.

Shipping Details:

35-45 days for injection mold, parts delivery time depends on production quantity.

Our advantage

We have more than 20 years experience in mold making.

Our employees have rich production experience and skilled technicians.

Provide customers with high-quality molds.

We provide high precision, efficient production and fast delivery.

Moulds will be produced according to your samples, ideas or technical drawings.

One-stop service from design to mold testing.

FAQ

Question 1: Are you a trading company or a manufacturer?

We are 100% direct factory, professional mold maker.

Question 2: How long is your delivery time?

Delivery time is about 30-170 days after payment, depending on mold complexity and shipment date

Question 3: Do you provide samples? Is it free or extra?

Yes, we can provide samples for free, but do not pay shipping.

Question 4: Can you produce by sample?

The molds will be produced according to your samples or technical drawings.

Question 5: What are your payment terms?

Mould payment: 40% deposit by wire transfer in advance, 30% prepayment for the second mould payment

Send first trial samples, 30% mold balance after you agree to final samples.

Production payment: 40% deposit in advance, 60% before shipment.

Hot Tags: car bumper plastic injection mold, china, manufacturer, supplier, factory, customized, low price, buy discount, free sample, made in china, paint bucket plastic mold, rapid prototyping/plastic injection molding, plastic fan cover mold , Storage box plastic mold, tail lamp lens cover mold, plastic basin mold, etc.

(For more details, please feel free to contact us.)

Injection molding is a manufacturing process in which a material, usually a type of plastic, is melted and injected by a machine into a mold. The mold is then cooled, and the solidified part is removed from the mold. Injection molding is used to produce a wide variety of parts, including car parts. Some examples of car parts that may be produced using injection molding include dashboard components, door panels, and air intake manifolds. The process is efficient and can produce parts with a high level of accuracy and repeatability.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Car Bumper Bracket Plastic Injection Mould Manufacturers and Wholesale Car Bumper Bracket Plastic Injection Mould Suppliers. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

OEM Household plastic chair mould making dining Office plastic armless chair molding

-

Durable Coat Hanger Plastic Injection Mould

-

Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Tail Light Mould

-

Motorcycle Headlamp Housing Plastic Injection Mould

-

Motorcycle Taillight Lampshade Injection Mold

-

Car Bumper Bracket Plastic Injection Mould

-

Automotive Led Front Fog Lamp Parts Plastic Molds

-

Car Front Bumper Injection Mould

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Auto Headlight Plastic Injection Mold

-

Auto Precision Sensor Injection Mold

English

English 中文简体

中文简体