Views: 0 Author: Site Editor Publish Time: 2020-07-20 Origin: Site

When you pick a PET Preform Mould for your bottle, you need to look at quality, material, and if the specifications match exactly. Making plastic bottles means you must think about neck size, preform weight, cooling time, and how many bottles you want to make. Here is a quick summary:

Factor | Description |

|---|---|

Neck Size | Changes how the PET Preform Mould is made and if it fits the machines. |

Preform Weight | Changes how long it takes to cool and how fast you can work. |

Cooling Time | Changes how quickly you can make bottles. |

Production Volume | Shows how many bottles the PET Preform Mould can make and if it is right for you. |

GuangChao is a top supplier of PET Preform Moulds because they use new technology, are dependable, and care about food packaging and

PET uses. If you want to buy preform molds for packaging, you can trust GuangChao to give you good preform quality every time.

Pick the right PET preform mould by looking at neck size, preform weight, cooling time, and how many bottles you need to make. These things change how good your bottles are and how fast you can make them.

Use strong materials for your moulds. Materials like stainless steel and special plastics last longer and cost less to fix over time.

Make sure the preform fits your bottle type and how you will use it. This stops leaks and makes sure your bottles work well and are safe.

Follow the rules for your industry and check safety standards. This keeps your moulds safe for customers and protects your company.

Use a checklist when you pick a mould. This helps you not make mistakes and helps you pick the best mould for your needs.

You see PET preforms almost every day, even if you do not realize it. A PET preform is a small plastic tube. Factories use these to make bottles for water, juice, and medicine. First, the preform gets heated. Then, it is

. This makes the bottle shape. This way, bottles are strong, clear, and safe for food or drinks.GuangChao is a top company in this area. If you buy preform molds from GuangChao, you get products made with new technology. They check quality very carefully. Their team uses 3D printing and CNC machines to design molds for your needs. You can trust their experience to give you good results.

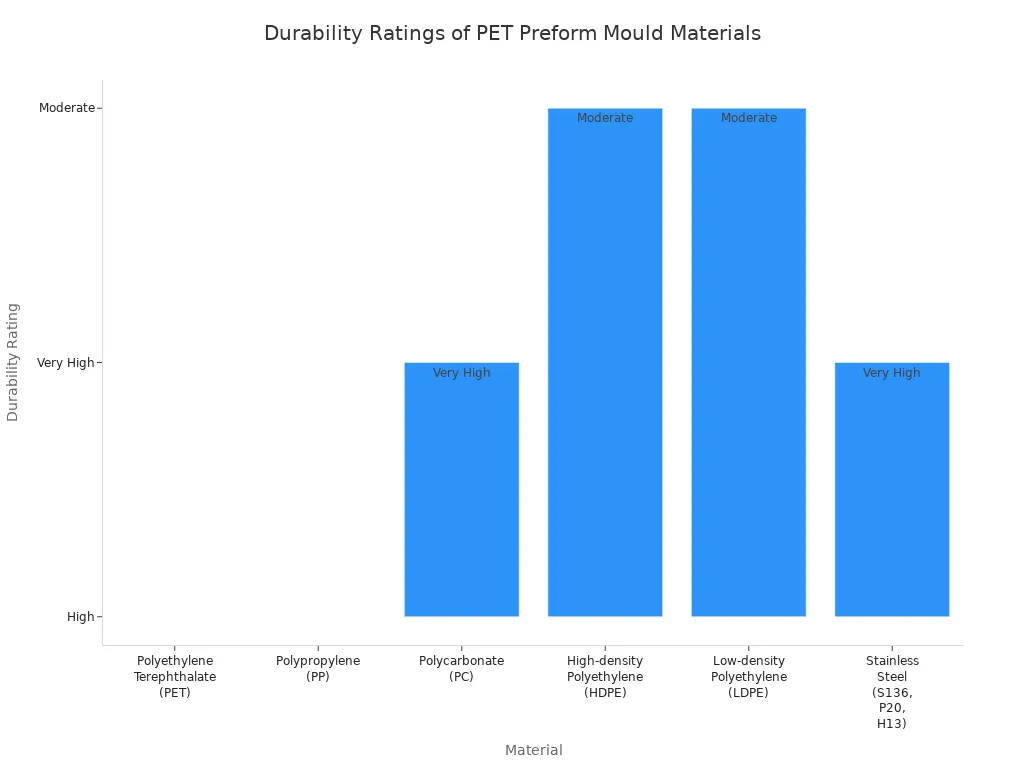

Here is a table that shows common materials used in PET preform moulds and how long they last:

Material | Durability Rating | Key Properties |

|---|---|---|

Polyethylene Terephthalate (PET) | High | Excellent strength, clarity, recyclability, good barrier against gases and contaminants |

Polypropylene (PP) | High | Excellent chemical resistance, suitable for high-temperature applications |

Polycarbonate (PC) | Very High | Exceptional strength, impact resistance, transparency for visibility |

High-density Polyethylene (HDPE) | Moderate | Flexibility, chemical resistance, cost-effective |

Low-density Polyethylene (LDPE) | Moderate | Flexibility, cost considerations |

Stainless Steel (S136, P20, H13) | Very High | Corrosion resistance, durability, polishability |

PET is used for bottles in food and drink packaging. PP is good for medicine and personal care items. PC is best for things that need to be very strong, like car fluids.

Picking the right PET preform mould is important for your business. You want bottles that look nice and last a long time. Good materials and careful design matter a lot. GuangChao uses strong metals like stainless steel and special plastics to make molds that last for many uses.

Careful design helps your molds work better and last longer. If you use well-made molds, you get fewer mistakes and better bottles. Quality checks measure the size and thickness of each preform. Tools like calipers and ultrasonic gauges help you make sure every piece fits your machines.

When you pick a mold, you should:

Check the material quality and design.

Look at the cooling system and how well it resists wear.

Ask for certifications and warranties.

You can follow these steps before you buy a mold:

Decide how many bottles you need and how many cavities you want.

Ask for CAD drawings from trusted suppliers.

Check for ISO 9001 and FDA certifications.

Look at test results for size and thickness.

If you pick a mold with strong materials and good design, you will save money and have fewer problems when making bottles.

Choosing the right sizing parameters is one of the most important steps in the molding process. You need to look at weight, neck diameter, and length. Each factor affects how your bottles perform and how well they fit with caps and machines.

Weight is the first thing you should check when selecting a preform for your bottle. The weight of the preform decides how much material goes into each bottle. If you use the right weight, your bottles will be strong and will not break easily. Too little weight can make bottles weak. Too much weight can waste material and increase costs.

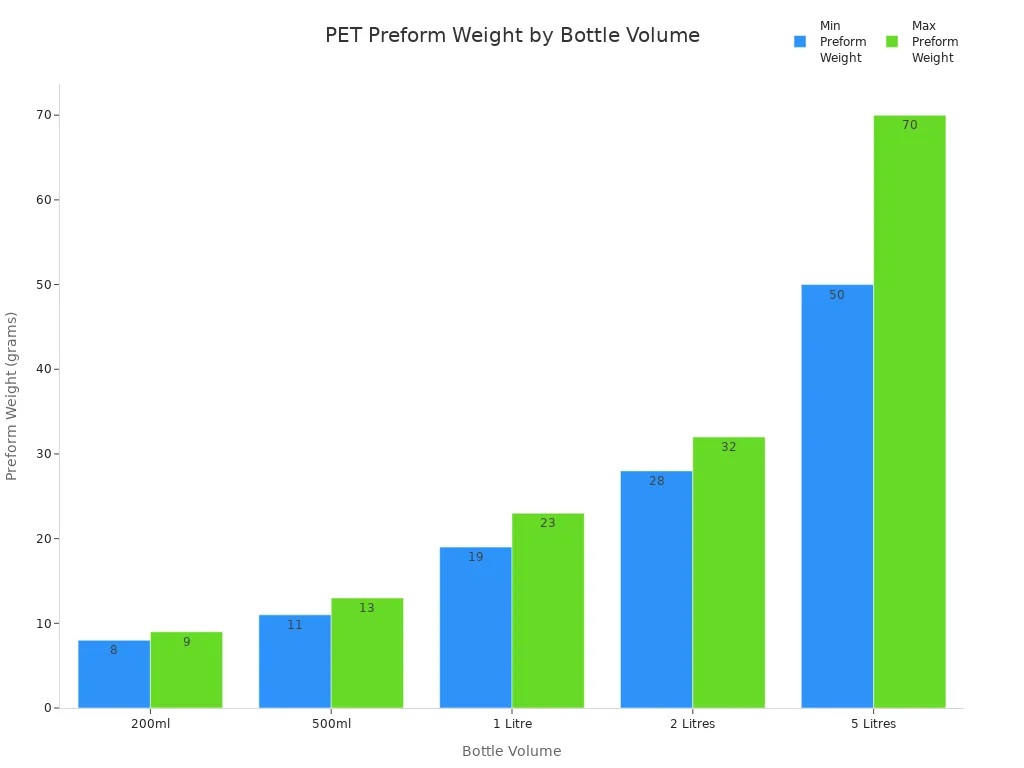

Industry standards help you pick the right weight for each bottle size. Here is a table that shows common weights for different bottle volumes:

Bottle Volume | Preform Weight | Neck Type | Typical Use |

|---|---|---|---|

200ml | 8–9 grams | 28mm Alaska | Water / Juice Bottles |

500ml | 11–13 grams | 28mm Alaska / PCO | Water / Flavoured Drinks |

1 Litre | 19–23 grams | PCO 1810 or 1881 | Carbonated Drinks / Oils |

2 Litres | 28–32 grams | 3-Start / Wide Neck | Soda / Edible Oil |

5 Litres | 50–70 grams | 38mm or Wide Mouth | Bulk Water / Oil Packs |

You can see that larger bottles need heavier preforms. This helps the bottle keep its shape during the molding process. Always match the preform weight to your bottle size for the best results.

Neck diameter is another key part of the molding process. The neck must fit the cap and the filling machine. If you choose the wrong neck size, you can have leaks or caps that do not fit. You also risk problems during filling and sealing.

The Bureau of Indian Standards (BIS) sets rules for neck sizes and tolerances. These rules help keep bottles safe for food and drinks. They also make sure bottles work with tamper-evident caps, which is important for many products.

Variations in neck diameter and thread design can lead to poor sealing, leakage, and difficult application.

Height specifications must be compatible to avoid issues like leakage and difficult closure application.

When you follow these standards, you get bottles that seal well and keep products safe.

Length is the last sizing parameter you need to check. The length of the preform affects how the bottle stretches during the molding process. If the preform is too short, the bottle may not reach the right height. If it is too long, the bottle can become thin and weak in some areas.

You must match the preform length to your bottle design. This helps you get even wall thickness and a strong final product. Material compatibility also matters. Different materials expand and contract at different rates during molding. This can change the final length and shape of your bottle.

Note: Always test your preform length with your molding machines before starting full production. This helps you avoid problems with bottle height and closure fit.

The right sizing parameters help you get bottles that look good, work well, and meet industry standards. When you use a high-quality pet preform mould, you can trust that your bottles will have the right weight, neck diameter, and length every time.

When you choose a bottle neck, you often see standard sizes in the market. These sizes help you match caps and closures easily. You save time and money because standard necks fit most machines and filling lines. Many companies use the 38-400 neck finish. This size works for bottles from 4 ounces to 1 gallon. You can use it for water, juice, or even thicker liquids. The IPEC neck finish is another popular choice. It gives you a tamper-evident seal, which keeps drinks safe and fresh.

Here is a table that shows the most requested neck options for PET bottles in the beverage industry:

Neck Finish | Description |

|---|---|

38-400 | The most versatile closure neck size, found on various bottle types, suitable for viscous liquids. |

IPEC | Provides a tamper-evident seal, ideal for beverages like juice and lemonade. |

You can see these neck finishes on many bottles in stores. They make the process of bottling and sealing much easier.

Sometimes, your product needs a special neck design. You might want a unique look or a new type of closure. Custom necks let you create bottles that stand out. You can ask for special threads, shapes, or tamper-proof features. When you choose custom requirements, you need a pet preform mould that matches your design. This means the mold must be made just for you.

Custom necks increase production costs. You need unique tooling and longer lead times. Standard neck finishes cost less because you use existing molds and parts. Custom designs give you more options, but you must plan for extra time and investment. GuangChao can help you with both standard and custom necks. Their team uses advanced technology to make sure your preform fits your needs.

If you want to create a new bottle style, talk to your supplier early. You can share your ideas and get advice on the best process for your project.

38-400 Neck Finish: Versatile, fits many closures, easy to use.

IPEC Neck Finish: Tamper-evident, keeps drinks safe, popular for juices.

You can choose a standard neck for speed and savings, or a custom neck for a unique product.

You need to match the right preform to your bottle type. Each bottle has its own shape, size, and purpose. Water bottles, juice bottles, and medicine bottles all need different designs. You must look at the shape and volume of your bottle before you choose a pet preform mould. Some bottles need a wide mouth for easy pouring. Others need a narrow neck for safe sealing. You should check if your bottle will hold still liquids or carbonated drinks. Carbonated drinks need stronger bottles because they hold pressure inside.

Here is a table that shows how bottle types match with preform features:

Bottle Type | Common Features | Preform Design Focus |

|---|---|---|

Water Bottle | Lightweight, clear | Thin walls, standard neck |

Juice Bottle | Medium weight, colored | Custom neck, thicker wall |

Medicine Bottle | Small, secure closure | Precise neck, strong wall |

The application of your bottle changes the way you select your pet preform mould. You must think about what your bottle will hold and how it will be used. The process starts with knowing your product and its needs. Here are some things you should consider:

Product type and intended use. You need to know if your bottle will hold hot liquids, cold drinks, or chemicals. Each product has different needs for temperature, light, and shelf life.

Wall thickness and durability. Bottles that travel long distances need thicker walls. This helps them resist bumps and drops.

Neck design and closure compatibility. You must pick a neck that matches your cap or closure. Some products need tamper-evident seals for safety.

For example, bottles for carbonated drinks need to be strong. They must handle pressure inside. These bottles use heavier preforms and special designs. Bottles for still water do not need as much strength. You can use lighter preforms and standard necks.

You can choose a standard mold when you want a quick and cost-effective solution. Standard molds use common shapes and neck finishes. These molds work well for most bottles you see in stores. You save time because you do not need to design a new mold. Standard molds fit many machines and help you start production fast. GuangChao offers a wide range of standard molds that meet industry requirements. You get reliable results and easy maintenance with these molds. If you need to make water or juice bottles with popular sizes, a standard mold is a smart choice.

Sometimes, your product needs something special. Custom molds let you create unique bottles that stand out on the shelf. GuangChao can design a custom pet bottle preform mold just for you. You can pick the color, shape, and size that matches your brand. Customization helps your bottle look different from others. It also lets you improve how your product works.

Here are some benefits of choosing a custom mold:

You can make your brand easy to recognize with special shapes or colors.

You can design preforms that use less material, which saves money and helps the environment.

You can make sure your bottle fits special caps or closures.

You can improve shipping by making bottles lighter or easier to pack.

Custom molds help you meet special needs and support your brand’s goals. GuangChao’s team works with you through every step of the process. You get a mold that matches your vision and helps your product succeed.

You often see small bottles in stores. These bottles usually hold between 250ml and 500ml. They work well for water, juice, and medicine. Small bottles need preforms that weigh less, usually between 25g and 40g. You can check the table below to see the typical size ranges:

Bottle Type | Size Range (ml) | Preform Weight (g) |

|---|---|---|

Small | 250ml - 500ml | 25g - 40g |

Large | 1 liter and more | 40g - 70g |

When you choose a pet bottle preform mold for small bottles, you should look for molds that make thin walls and precise necks. Injection blow molding works best for these bottles. This method helps you get clear and strong bottles with smooth finishes. You can use these bottles for drinks, personal care, or medicine.

Tip: Small bottles need accurate neck sizes. This helps you avoid leaks and makes sure caps fit tightly.

Large bottles hold 1 liter or more. You often use these bottles for bulk water, oils, or cleaning products. Large bottles need heavier preforms, usually between 40g and 70g. These bottles must be strong because they carry more weight. You can see the differences in molding types in the table below:

Molding Type | Suitable Bottle Size | Key Characteristics |

|---|---|---|

Extrusion Blow Molding | Medium to Large | Flexible process, cost-effective for complex structures, suitable for HDPE and PP. |

Injection Blow Molding | Small | Mainly for small-capacity containers, below 500 ml, with limitations for larger sizes. |

For large bottles, extrusion blow molding gives you more flexibility. You can make bottles with special shapes or handles. This process works well for pet and other plastics. You should choose molds that help you get thick walls and strong bases. Large bottles need to resist drops and bumps during shipping.

Note: Always test your bottle design with your filling machines. This helps you avoid problems with sealing and strength.

When you begin making bottles, you must think about mold costs. The price changes based on the mold type you pick. Single-cavity molds are cheaper. They make fewer bottles each time. Multi-cavity molds cost more money. They help you make bottles much faster. Here is a table that shows how much each mold type costs:

Mold Type | Price Range |

|---|---|

Single-cavity | $10,000 - $15,000 |

Multi-cavity | $20,000 - $50,000 |

You should check your needs before you choose. If you want to make lots of bottles, multi-cavity molds save time. The first cost is higher, but you reach your goals quicker.

Tip: Always think about costs when you plan your budget. Spending more at first can help you get better results later.

Picking a good mold helps you save money over time. You spend less fixing problems and work faster. Cheaper molds may use weak steel and bad cooling. These issues slow you down and cost more.

Here are some ways good molds help you save:

Strong steel means you fix molds less often.

Good cooling lets you make bottles quickly.

Accurate molds mean fewer mistakes and lower costs.

You can see the difference in this table:

Aspect | Lower-Cost Alternatives | |

|---|---|---|

Material Waste | Reduced | Higher |

Operational Speeds | Enhanced | Slower |

Maintenance Costs | Lower | Higher |

Initial Investment | Higher | Lower |

Long-term Financial Benefits | Substantial | Minimal |

Good molds help you waste less material.

Faster speeds mean you make more bottles.

Lower maintenance costs save you money over time.

If you pick a strong pet mold, you fix it less and make more bottles. In the end, you save money and help your business grow.

You must follow strict rules when you select a mould for bottles used in food and beverage packaging. These rules help you keep your products safe and meet legal requirements. You need to check that your moulds meet standards set by organizations like the FDA. The FDA has rules for materials that touch food. These rules appear in 21 CFR Part 177, which covers indirect food additives such as polymers.

You should look for these key points when you review compliance:

Use only approved materials like PET, HDPE, PP, or PLA for food-contact bottles.

Make sure your supplier conducts migration testing. This testing checks if chemicals move from the bottle into the food or drink. The Overall Migration Limit (OML) must stay within safe levels.

Ask about Good Manufacturing Practices (GMP). These practices help keep quality high and reduce risks.

Confirm that your moulds follow industry standards and regulations. This step protects your brand and your customers.

Pay attention to mould maintenance. Clean and inspect your moulds often to keep product quality strong.

Tip: Always request certificates and test reports from your supplier. These documents show that your moulds meet all safety and compliance rules.

Food-grade safety matters for every bottle you produce. You want to make sure your bottles do not harm people or change the taste of food and drinks. You must use materials that pass safety tests and meet food-contact standards.

You should check these safety steps:

Choose moulds made from food-safe materials. PET is a popular choice because it is strong, clear, and safe for food.

Review migration test results. These tests show that your bottles do not release unsafe chemicals.

Make sure your supplier follows GMP. This practice keeps your production area clean and reduces contamination.

Inspect your moulds for damage or wear. Damaged moulds can cause defects in bottles and may lead to safety problems.

You protect your customers and your business when you follow these safety steps. Reliable moulds help you make bottles that meet all food-grade standards.

You want to make bottles quickly and without problems. Cycle time means how long it takes to make one group of preforms. If the cycle time is short, you can make more bottles faster. The way your preform injection mold is built is very important. GuangChao uses fast machines and smart designs to keep cycle times low.

Here is a table that shows how new machines help you work faster:

Machinery Type | Number of Cavities | Cycle Time (s) |

|---|---|---|

Netstal PETline | 60 | 9 |

A machine with 60 cavities can finish in just 9 seconds. This fast speed helps you fill big orders and save money. Good molds also mean you get fewer mistakes and bottles look the same. Fast cycles help the blow molding process go smoothly and help you deliver bottles on time.

Cooling systems are very important for making PET bottles well. You need a mold that cools fast and cools every part the same way. GuangChao molds have special cooling channels that help you make bottles faster and better.

Special cooling can make production 10-20% faster.

You get more good bottles and use less energy with better cooling.

Good cooling helps your preforms keep the right shape and size.

Modern cooling also keeps bottles strong and clear. You do not get bent or uneven bottles. This means your bottles look nice and last longer. If you pick a mold with good cooling and ejection, you make your factory work better and faster.

Tip: Always look at the cooling system before you buy a mold. Good cooling helps you save time and money.

New tools like CAD design, automation, and real-time checks help a lot too. These tools let you find problems early and keep your line running well. You make more bottles, get better quality, and waste less.

When you select a PET preform injection mold, you want to avoid mistakes that can slow down your production efficiency or hurt your product quality. Many people make the same errors, but you can learn how to spot and fix them.

You might think one size fits all, but that is not true for preforms. Sizing errors can cause big problems in the blow molding process. If you use a universal neck size, you may find that caps fit too loosely or too tightly. This can lead to leaks or bottles that do not seal well. Your brand image can suffer if customers get bottles that leak or break.

Caps that do not fit right increase rejection rates.

More rejected bottles mean higher costs and wasted time.

Poor sizing also makes your packaging look inconsistent.

Always check that your preform matches your bottle and cap exactly. This step keeps your products safe and your customers happy.

You need to match the preform to the exact volume of your bottle. If you ignore this, your bottles may not hold the right amount of liquid. This mistake can cause problems with labeling, shipping, and customer trust.

Using the wrong preform weight can make bottles too weak or too heavy.

Bottles that do not match the intended volume can lead to complaints or returns.

Your production efficiency drops when you have to stop and fix these issues.

Tip: Test your preform with your filling line before starting full production.

You must follow safety and quality rules when you choose a mold. Overlooking compliance can lead to unsafe bottles or legal trouble. Some common mistakes include:

Not checking if the mold can handle high temperatures. This can cause the mold to lose strength during operation.

Forgetting about corrosion resistance. Decomposition gases can wear down the mold and make the surface rough.

Ignoring heat and cold fatigue resistance. Molds that cannot handle repeated heating and cooling may fail early.

Compliance Factor | Why It Matters |

|---|---|

High Temperature | Keeps mold strong during production |

Corrosion Resistance | Prevents early wear and rough surfaces |

Fatigue Resistance | Extends mold life and reliability |

Always ask your supplier for certificates and test results. This step helps you keep your bottles safe and your business running smoothly.

You want to choose the best PET preform mould for your bottles. A clear checklist helps you avoid mistakes and improve production efficiency. Follow these steps to make sure you get the right mold every time:

Preparation

Gather all your bottle specifications. Know the volume, neck size, and shape you need. List your production goals and the type of preform injection mold you want.

Visual Checks

Look at the mold for any visible flaws. Check for cracks, dents, or uneven surfaces. A smooth and clean mold gives you better results in the blow molding process.

Dimensional Measurements

Use calipers or gauges to measure the mold’s key parts. Make sure the neck diameter, length, and cavity size match your bottle design. Dimensions are crucial to avoid blowing and capping failures.

Weight Consistency

Weigh several preforms from the mold. Each preform should have the same weight. Inconsistent preform weight affects bottle quality and costs.

Material Property Analysis

Test the intrinsic viscosity (IV) value and acetaldehyde (AA) levels of the PET material. These properties impact the final product’s strength and safety.

Heating Tests

Heat the preform and check how it reacts. The preform should soften evenly without bubbles or burns. This step helps you see if the mold works well with your chosen material.

Final Trial Blow

Run a real-world trial blow. Use the mold to make a sample bottle. Check the bottle for clarity, strength, and fit. A trial blow confirms the mold’s quality before you start full production.

Tip: Always keep a record of your test results. This helps you track changes and improve efficiency over time.

Before you place your order, review your findings. Use this checklist to make sure you did not miss any step:

Did you check all dimensions and weights?

Did you test the material properties?

Did you run a successful trial blow?

Did you inspect the mold for flaws?

Did you confirm the mold matches your production needs?

If you answer “yes” to every question, you are ready to move forward. Reliable molds help you boost production efficiency and reduce waste. You get bottles that look good, seal well, and last longer. When you follow this checklist, you protect your brand and keep your customers happy.

Note: A careful review at each step helps you avoid costly mistakes and keeps your blow molding process running smoothly.

You can pick the best pet preform injection mold by looking at quality, how well it works, and if it follows rules. Experts say you should use strong steel, molds with many cavities, and cooling systems that work fast. Smart sensors and automatic controls make the blow molding process better. GuangChao is known for using new technology, being very reliable, and checking quality carefully.

Feature | GuangChao Mould | Other Suppliers |

|---|---|---|

Reliability | Strong reputation | Varies |

Technology | Advanced integration | May lack innovation |

Customer Satisfaction | Consistently exceeds | Varies widely |

Use the checklist and ask experts for the best results.

A PET preform mold shapes melted plastic into small tubes called preforms. You use these preforms to make bottles for drinks, medicine, or other products. The mold helps you get the right size and shape every time.

You should check your bottle’s size, neck type, and weight. Ask your supplier for samples and test them with your machines. This step helps you avoid mistakes and get bottles that fit your needs.

Mold efficiency means you make more bottles in less time. You save money and reduce waste. Fast molds help you fill big orders and keep your business running smoothly.

You cannot use one mold for many sizes. Each mold fits a specific bottle shape and volume. If you want different bottles, you need separate molds for each type.

You should clean your molds often and check for damage. Regular maintenance helps you avoid problems and keeps your bottles looking good. Ask your supplier for tips on mold care.