Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

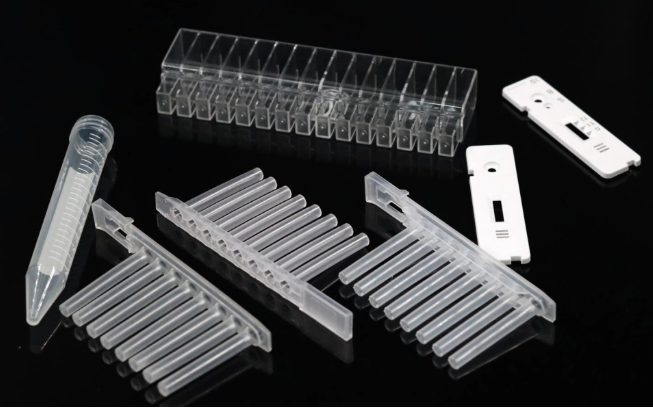

Mould maintenance is very important in the medical field. Taking good care of each mold affects how good medical tools are. Clean and cared-for molds stop germs and keep products the same quality. If a mold is not cared for, big problems can happen, like broken tools or rule issues. Regular maintenance helps a lot in making medical molds. Every mold needs care to stop damage and keep products safe. GuangChao knows that mould maintenance affects all parts of medical product quality.

Cleaning and taking care of molds often keeps medical products safe. It also keeps them high quality by stopping defects and contamination. Bad mold care can cause broken parts and germs. It can also lead to product recalls. These problems can cost a lot and be dangerous. Having a clear plan for maintenance helps a lot. This plan should have daily, weekly, monthly, and yearly tasks. This makes molds last longer and work better. Using safe cleaning agents is important. Controlling contamination is also needed. Watching molds with technology helps keep products safe. It also lowers mistakes. Writing down all maintenance work is important. This helps with quality control and following rules. It

also helps things get better over time.

Mould maintenance is very important for good medical consumables. Each step in taking care of molds changes how well medical plastic injection molds work. When workers check how the mold releases parts, they can stop parts from sticking. This also helps keep the surface from getting worse. If they measure the contact angle on hot molds right away, they can clean or add release agents fast. Using this information helps make better products and more of them in medical plastic injection molds.

Good injection molding needs the mold to stay the same every time. Keeping a regular maintenance plan helps stop problems and keeps quality high. Medical plastic injection molds need careful control of temperature, pressure, and speed. Even small changes in these things can change the final product. GuangChaouses special systems to watch every mold and make sure it meets tough quality rules.

Making medical devices needs everything to be very clean and exact. Good maintenance stops germs and makes sure each plastic part follows the rules. Quality teams look at molds for dirt, damage, or wear. They write down every maintenance job to see how it affects product quality. This helps make things easier to build and lowers the chance of problems in injection molding.

Tip: Checking and cleaning molds often keeps the material good and helps medical plastic injection molds last longer.

If you do not take care of molds, big problems can happen in medical plastic injection molds. Not cleaning or fixing molds on time lets the surface get worse. This causes more mistakes and lower product quality. Problems like flash, vacuum voids, warping, and discoloration can happen when maintenance is bad.

| Defect Type | Description & Cause Linked to Mold Maintenance | Prevention / Notes |

|---|---|---|

| Flash | Extra material leaks out if the mold does not close tight or parts are worn. | Use more force to close; keep mold in good shape to stop leaks. |

| Vacuum Voids | Air pockets or not enough material from bad venting or mold design. | Make venting better; fill mold fully; keep mold clean to stop air or gas. |

| Warping | Cooling is not even or mold design is bad, so parts bend. | Cool slowly; keep wall thickness the same; design and care for mold well. |

| Discoloration | Old resin or dirt from not cleaning mold and tools. | Clean mold and machine well between uses; handle materials right. |

| Surface Delamination | Flakes from dirt or water, maybe from release agents. | Store materials right; use fewer release agents; keep mold clean. |

| Burn Marks | Air or resin gets too hot from bad venting or too much heat. | Lower melt or mold heat; vent better; keep mold able to let air out. |

| Sink Marks | Cooling is not even in thick spots, making dents. | Make cooling channels better; design and care for mold to cool evenly. |

| Weld Lines | Weak lines where melted plastic meets, changed by mold design and heat. | Move gates; keep mold at right heat; design mold for good flow. |

| Short Shots | Mold does not fill all the way from bad flow or mold shape. | Make flow better; keep mold in good shape to stop blockages. |

Bad maintenance also makes it easier for germs to get into medical plastic injection molds. Water leaks, too much moisture, and bad air systems help mold grow. Dirty molds can put spores in plastic parts, which is dangerous for patients. Some real cases show how bad maintenance can cause big problems:

Sanofi Pasteur’s Toronto plant had flooding and mold, so vaccines were recalled and there were shortages.

The New England Compounding Corporation outbreak made many people sick and caused deaths because of mold in medicine.

Some pills were recalled when mold from wooden pallets got into the products.

These stories show that bad maintenance can stop medical device production and cost a lot of money. Makers must fix hard-to-clean spots, deep cuts, and tricky shapes in medical plastic injection molds. Cleaning often, using purging compounds, and checking molds carefully help keep injection molding quality high.

Medical plastic injection molds always need care for easy building and good quality. By making mould maintenance important, companies like GuangChao keep products safe, lower mistakes, and make sure medical consumables are good and safe.

Good cleaning and stopping rust are very important for injection mold maintenance in the medical field. Every medical plastic injection mold must stay clean from dust and dirt. This helps keep high quality injection molding. Workers check molds often to find early signs of damage or wear. They look at parts like runners, cavities, gates, plates, and sprues. Using compressed air, they blow away dust and small bits that could hurt the injection molding process.

Medical plastic injection molds need to be cleaned with safe solvents. Isopropyl alcohol is a top choice because it is safe for medical and food use. Workers use hand-spray pump bottles and lint-free wipes instead of sprays. This stops new dirt from getting into clean rooms. Aerosol sprays are not allowed because they can bring in bad stuff.

Lubrication and stopping rust are also key steps. Food-safe lubricants and rust preventives protect mold surfaces without leaving bad stuff behind. Some rust preventives do not need to be removed before making products. This lowers the chance of dirt during the injection molding process. Mold Shield and Quick Rust Preventive are good examples. They protect for a long time and go away when the mold heats up. This makes them great for high quality injection molding in medical places.

A set schedule helps every medical plastic injection mold get the care it needs. The table below shows how often to do maintenance:

| Maintenance Frequency | Description |

|---|---|

| Daily | Quick checks, cleaning, and oiling moving parts |

| Weekly | Regular preventive maintenance jobs |

| Monthly | Deep cleaning, taking apart things like ejector units |

| Annual | Full maintenance, deep cleaning, and repairs |

Workers should clean molds after each use, especially with sticky resins or tough work areas. They use hand cleaning, ultrasonic cleaning, or dry ice blasting, depending on how hard the mold is. Before putting molds away, workers make sure they are dry, clean, oiled, and covered with rust preventives. Keeping molds in rooms with good air and temperature stops rust and damage.

GuangChao says it is important to write down every maintenance job. By counting how many times a mold is used before cleaning, makers can make the injection molding process better and help molds last longer. This helps make building easier and keeps high standards for medical plastic injection molds.

Tip: Always pick NSF-approved cleaners and rust preventives. This meets strict medical rules and stops contamination.

Contamination control is very important for keeping medical plastic injection molds good. Even a little oil, grease, or dust can make medical products unsafe. Workers must fix oil leaks fast and clean up grease to stop dirt from getting on machines and plastic parts. Using the right hopper lids and cleaning hoppers between material changes keeps raw materials clean.

Operators should use just enough lubricant on moving mold parts. Too much lubricant can get on mold surfaces and cause problems in the injection molding process. This can make plastic products have defects. Drying raw materials before use stops water from causing problems like warping or color changes in medical plastic injection molds.

Strict cleaning rules are needed in medical factories. Operators must follow cleaning steps, not eat or drink near work areas, and keep themselves clean. Checking cleaning rules often makes sure everyone knows and follows contamination control steps.

Good air systems help lower contamination risks. Air filters take out dust from the air. Keeping the right temperature and humidity stops plastic from getting worse. Less dust and dirt helps both the injection molding process and the final medical product.

Water treatment stops scale, rust, and slime from building up in mold cooling channels. After taking out a mold, workers run cleaning solutions through the channels to clear them. Solutions like OxSol, Filmex 100, and Algex 200 fight certain dirt, while CharPrep finishes the job. Changing cleaning solutions often keeps them working well.

Better contamination control makes medical consumables safer and stronger. Stopping weak sticking at the tiny level helps products work better and lowers the chance of problems or recalls. Special tools can check how well surfaces are cleaned, helping meet rules and keeping good records. Contact angle tools help watch and keep surface quality every shift. This means more products and fewer mistakes in medical plastic injection molds.

New technology, like automation and digital tools, has changed injection mold maintenance. Automated systems stop human mistakes, keep things the same, and lower contamination risks. Real-time mold monitoring software watches how molds work from start to finish. This makes the injection molding process better and helps high quality injection molding. GuangChao uses these new tools to make safe, strong, and high-quality medical plastic products.

Note: Automation makes products better and also helps workers stay safe by needing less hands-on work in the injection molding process.

How long an injection mold lasts depends on how well it is cared for. A good maintenance plan helps molds work longer and saves money on repairs. Workers clean molds after each use to remove dirt and water. This stops rust from forming. They check switches and make sure machines are level to avoid problems. Hydraulic oil and seals are checked often to keep machines working well. Electrical parts are looked at to stop loose wires and dirt. Filters get changed, and moving parts are oiled to stop them from wearing out.

GuangChao uses strict routines to help molds last longer. Regular checks help workers find damage and fix it early. This stops breakdowns and bad parts. Preventive maintenance takes time and effort, but it helps avoid sudden stops and keeps work going. Keeping up with care makes more products and better quality. Molds with anti-corrosion coatings and regular care can last up to 1.2 million cycles. This is about 30% longer than molds without coatings.

Tip: A good maintenance plan helps molds last longer and keeps medical consumables safe.

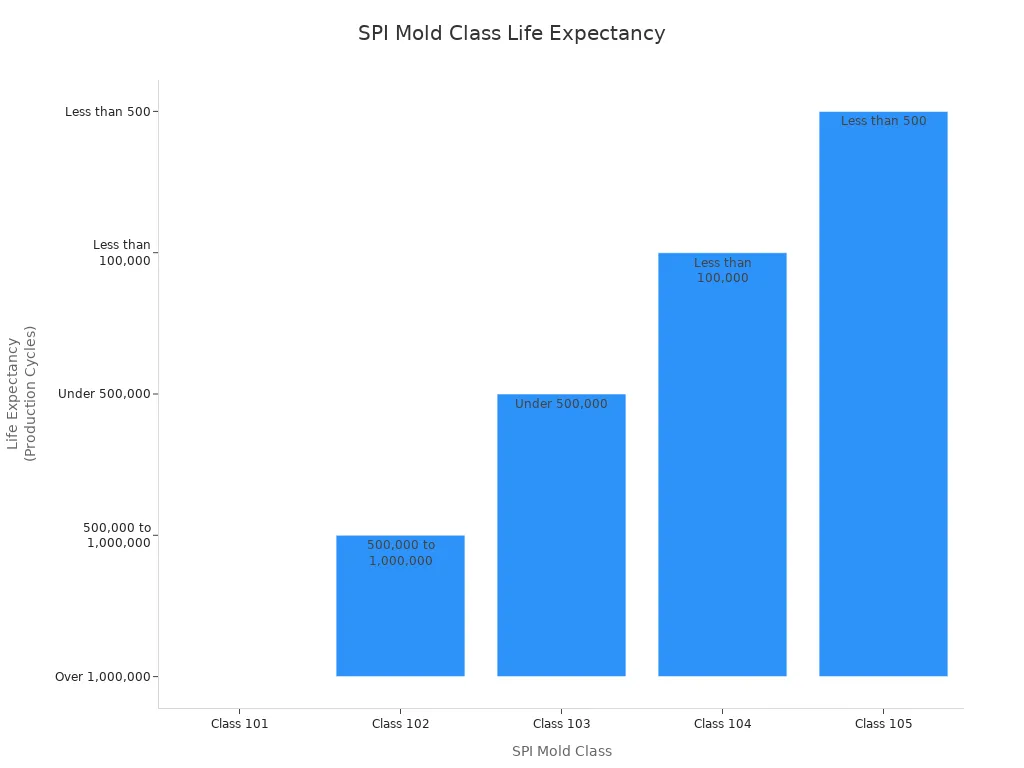

Manufacturers count how many times a mold is used to measure its life. SPI mold classes show how long each mold should last. Medical consumables molds are usually Class 101 or 102. These molds can be used between 500,000 and over 1,000,000 times. The table below shows how many cycles each SPI mold class can handle:

| SPI Mold Class | Life Expectancy (Production Cycles) | Description |

|---|---|---|

| Class 101 | Over 1,000,000 | High-production molds with highest durability and cost |

| Class 102 | 500,000 to 1,000,000 | Medium-to-high volume molds with good surface finish |

| Class 103 | Under 500,000 | Medium volume molds with lower cosmetic requirements |

| Class 104 | Less than 100,000 | Low volume or prototyping molds |

| Class 105 | Less than 500 | Prototype molds, least expensive |

Important things for mold life are cycle count, material quality, how the mold is used, and how it is cared for. Steel molds last the longest. Aluminum molds do not last as long. Clean rooms and good cooling help molds work better and last longer. Special coatings like PVD make surfaces smoother and reduce damage. GuangChao uses these ideas to help molds last longer and make good medical consumables.

A good maintenance schedule helps keep medical plastic injection molding strong. Workers and maintenance teams do daily, weekly, quarterly, and yearly jobs to keep each mold working well. At the start of each shift, workers check guards, Plexiglas, and emergency stops. They make sure main disconnects and electrical cabinet doors are closed tight. They look at fluid levels, like hydraulic and lubrication oils, to make sure they are right. Quick checks help find oil leaks early.

Maintenance teams look for leaks and overheating in equipment. They check pump groups, electrical wires, and pipes for any damage. Listening for strange sounds helps find problems before they get worse. Hydraulic manifolds and oil basins are checked for leaks. These steps are important for regular maintenance.

| Interval | Recommended Maintenance Tasks |

|---|---|

| Daily | Visual inspection of machines; clean oil filters; inspect all machine safeties. |

| Weekly | Inspect hoses and cylinders for leaks and alignment; clean air filters on electrical cabinets. |

| Quarterly | Detailed maintenance check; verify power line tightness; check heater circuits; grease lubrication points. |

| Annual | Comprehensive maintenance; adjust settings; replace worn parts. |

GuangChao follows these steps to make sure every medical plastic injection mold meets high standards. Doing maintenance after a certain number of uses or after some time helps production go smoothly and makes molds last longer.

Tip: Checking molds often and keeping records helps keep molds ready and makes medical plastic injection molding better.

Keeping good records is a big part of taking care of medical injection molds. Teams make schedules for regular mold care, including checks and cleaning after many uses. They write down every job, like cleaning, oiling, fixing, or changing parts. This makes clear instructions for how to care for, fix, and clean molds.

Maintenance logs show regular jobs and times when machines stop working. Quality control records show how many parts are made, if they are good, and if there are any problems. These records help teams see patterns, stop problems, and make things better. GuangChao uses detailed logs to keep getting better and to make the process work well.

Keeping careful records helps follow rules in medical injection molding.

ISO 13485 and FDA rules say you must keep records about materials, how things are made, and quality checks.

Good records help with audits, risk checks, and making sure products are safe and legal.

Good record keeping not only makes things clear but also helps keep making medical plastic injection molding better. Teams use these records to check rules, watch mold health, and make products better.

Taking care of molds is very important for making good medical consumables. Checking, cleaning, and oiling molds often helps stop problems and makes molds last longer. Medical teams have fewer issues and less waiting when they follow these steps. GuangChao uses special tools and plans to keep every mold working well. To get the best results, makers should:

Check and clean molds after every use.

Use sensors to watch heat and pressure all the time.

Teach workers how to care for medical molds the right way.

Good mold care keeps medical products safe and strong. It also helps factories make products for a long time.

The most important step is regular cleaning. Workers take off dirt and leftover stuff from all mold surfaces. This stops contamination and keeps medical products safe for people.

Experts say to check molds every day and do deep cleaning each month. GuangChao plans mold care by how much the molds are used and how much they need to make. Checking molds often helps find damage and makes them last longer.

Documentation means writing down every time a mold is cared for. Teams use these notes to follow rules and make quality better. Good records help companies like GuangChao avoid problems with the rules.

If molds are not cleaned well, defects and contamination can happen. Products might not pass safety tests. GuangChao teaches workers to clean every mold well to lower these risks.

GuangChao uses special coatings and strict care steps. Technicians look at each mold for damage and put on protective coatings. These actions help molds last longer and keep product quality high.