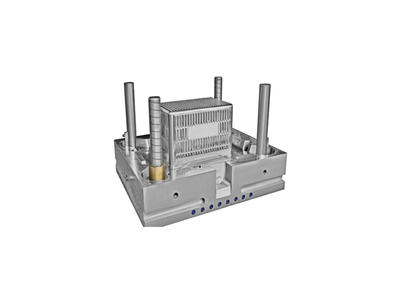

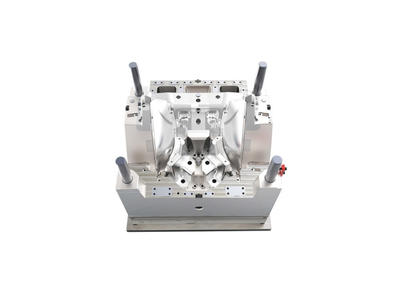

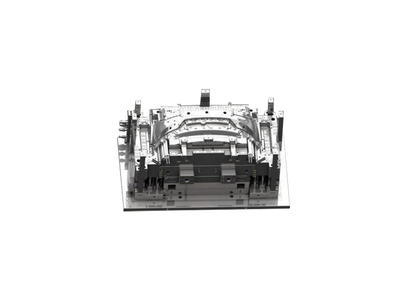

Motorcycle Taillight Lampshade Injection Mold

Name: Motorcycle Taillight Lampshade Injection Mold

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Mold material: 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61, etc. (hardness 35~55HRC)

Mold base: standard mold base, LKM, HASCO, etc.

Cavity: single/multiple

Runner: cold runner or hot runner.

Ejection system: motor/hydraulic cylinder/stripping plate/angle pin, etc.

Cooling system: core baffle and cavity plate chain drilling cooling

Design software: UG, PROE, CAD, CAXA, etc.

Plastic material: PP, PC, PS, PE, PU, PVC, ABS, PMMA, etc.

Finish: Polished, Textured, Sandblasted, Chrome

Mold life: 300000-5000000 times

Delivery time: Delivery time is about 30-170 days after payment, depending on mold complexity and shipment date

Packing: Standard export wooden box

Specifications: according to customer requirements

Details

FAQ

Medical laboratory product injection molding is a process used to manufacture plastic parts and components for use in a medical laboratory setting. In this process, melted plastic material is injected into a mold cavity, where it cools and solidifies into the desired shape. Injection molding is a cost-effective method for mass-producing plastic parts and is often used for producing components such as pipettes, test tubes, and other laboratory supplies. Injection molds can be made to produce parts with very precise dimensions and can be used to create complex shapes and features. The medical laboratory industry relies on injection molding to produce high-quality, accurate, and reliable products that are essential for conducting experiments and analyzing results.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Motorcycle Taillight Lampshade Injection Mold Manufacturers and Wholesale Motorcycle Taillight Lampshade Injection Mold Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

Revolving Logistics Storage Box Injection Mould

-

Outdoor Waste Sorting Box Plastic Injection Mould

-

Durable Coat Hanger Plastic Injection Mould

-

Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Tail Light Mould

-

Motorcycle Headlamp Housing Plastic Injection Mould

-

Car Bumper Bracket Plastic Injection Mould

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Medical Laboratory Disposable Micropipette Tip Mould

-

Medical vacuum blood collection tube mold laboratory micro reagent test tube mold

-

Medical Laboratory 96 Well Round Hole Deep Well Plate Plastic Injection Mold

-

Eight Cup Magnetic Sleeve Rod Mold

English

English 中文简体

中文简体