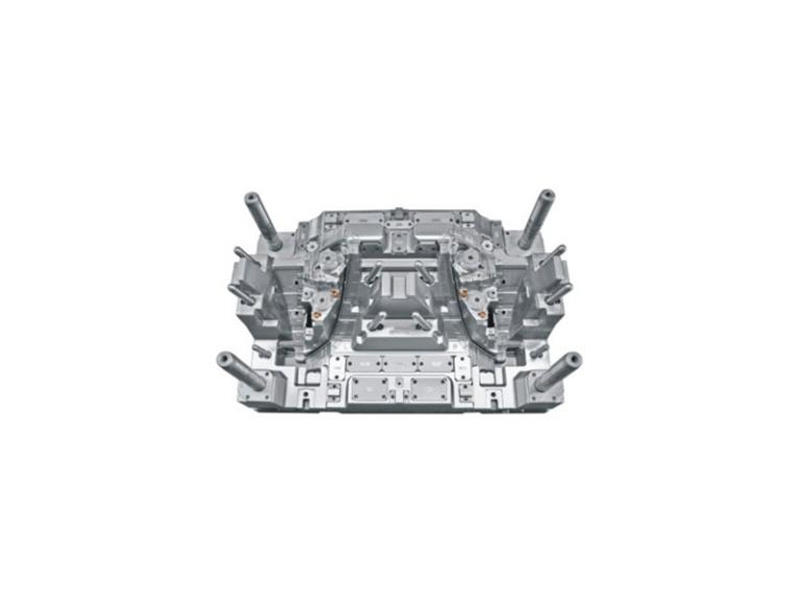

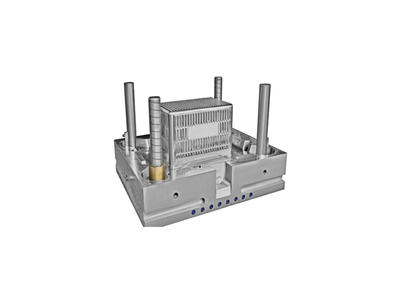

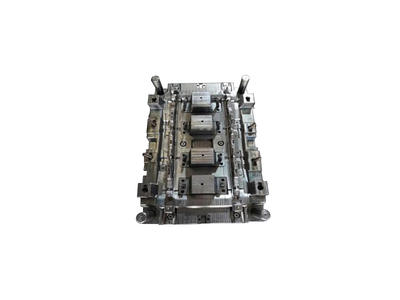

Auto Headlamp Housing Injection Mold

Product name: Auto Headlamp Housing Injection Mold

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Molding mode: plastic injection mold

Product material: plastic

Product: Auto Mould

Product name: car headlight shell mold

Mould material: P20/718H/738/NAK80/2343/S136

Plastic material: PP, PC, PE, ABS, PVC, etc.

Design software: CAD, CAXA, UG, PROE

Formwork: LKM, Harsco, etc.

Die life: >500,000 rounds

Cavity: single cavity

Surface Treatment: Polished

Size: Customized size

Details

Supply capacity

200 sets/year

Packaging and Delivery

Packaging Details: We pack the goods in wooden boxes or as required. After the final sample is confirmed, the mold will be sent to the port for shipment.

Port City:Ningbo

Production Process

FAQ

Q: What information is required for plastic mold quotation?

1. Sample photo of size or 2D/3D design

2. Die steel type

3. Number of cavities

4. Living Services

5. Injection molding machine parameters

Q: What are your packing conditions?

Usually, we pack the goods in wooden boxes or as required. The mold surface will be painted. Anti-rust oil is used inside the mold, plastic film is used outside, and standard export wooden boxes are used for seaworthy shipping. If you have a legally registered patent, we can pack the goods in your branded box after receiving your authorization.

Q: What is the delivery time?

Delivery time is about 30-170 days after payment, depending on mold complexity and shipment date

(For more details, please feel free to contact us.)

Injection molding is a manufacturing process in which a material, usually a type of plastic, is melted and injected by a machine into a mold. The mold is then cooled, and the solidified part is removed from the mold. Injection molding is used to produce a wide variety of parts, including car parts. Some examples of car parts that may be produced using injection molding include dashboard components, door panels, and air intake manifolds. The process is efficient and can produce parts with a high level of accuracy and repeatability.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Auto Headlamp Housing Injection Mold Manufacturers and Wholesale Auto Headlamp Housing Injection Mold Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

Revolving Logistics Storage Box Injection Mould

-

Durable Coat Hanger Plastic Injection Mould

-

Environmentally Friendly Plastic Cup Injection Mould

-

Motorcycle Tail Light Mould

-

Motorcycle Headlamp Housing Plastic Injection Mould

-

ABS plastic Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Turn Signal Lamp Plastic Injection Mould

-

Automotive Led Front Fog Lamp Parts Plastic Molds

-

Auto Precision Sensor Injection Mold

-

Medical Laboratory Disposable Micropipette Tip Mould

-

Medical Laboratory 96 Well Round Hole Deep Well Plate Plastic Injection Mold

-

Eight Cup Magnetic Sleeve Rod Mold

English

English 中文简体

中文简体