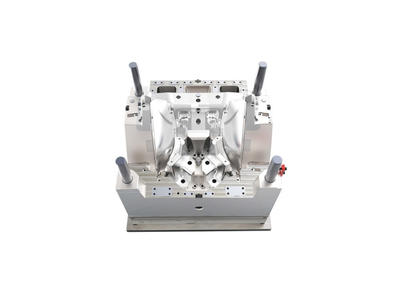

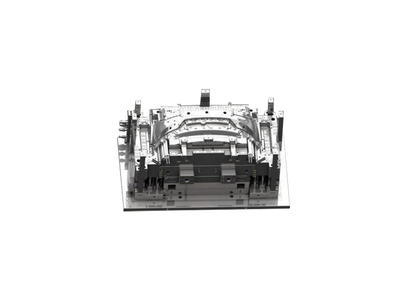

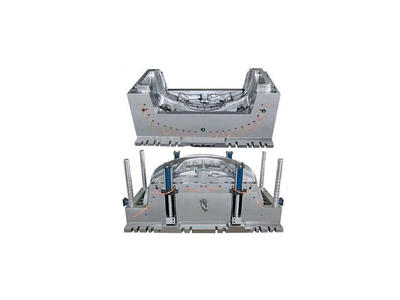

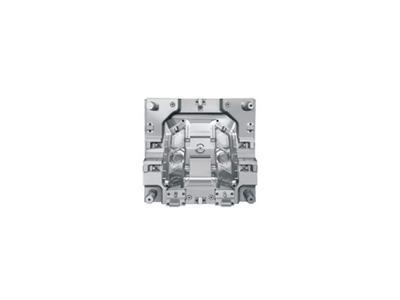

Eight Cup Magnetic Sleeve Rod Mold

Product name: Bailian Cup magnetic sleeve rod mold

Brand Name: Anno

Place of origin: Taizhou, Zhejiang, China

Molding mode: plastic injection mold, double injection mold

Product materials: Plastic, ABS, PP, PC, PA, PMMA, PS, POM, TPV, etc

Product: Eight union cup magnetic sleeve rod

Gate type: side gate, auxiliary gate, pin point gate, edge gate, etc

Mold materials: 45#, 50#, P20, H13, 718 2738, NAK80, S136, SKD61, etc

Mold library: Double leaf, LKM, Hasco, DME

Application: Magnetic rod sleeve with deep hole plate is used for nucleic acid extraction on the nucleic acid extraction machine. During the nucleic acid extraction experiment, the magnetic rod is protected from contamination and the service life of the magnetic rod is extended.

Through the up and down movement of the magnetic rod sleeve, the sample can be mixed, cracked, combined, washed and elution in the corresponding magnetic bead reagent.

Through the coordinated movement of magnetic rod and magnetic rod sleeve, the transfer of magnetic bead, magnetic bead-target material complex is realized.

Through the separation of magnetic rod and magnetic rod sleeve, the release of magnetic bead, magnetic bead-target material complex is realized. mould

Details

About us

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is a professional manufacturer of 98 deep hole plate, eight magnetic rod series products and high-quality mold R & D and manufacturing enterprises. Committed to becoming the provider of advanced deep hole plate and magnetic sleeve rod system solutions. Our company warmly welcome new and old customers to visit and patronage, warmly welcome the cooperation of people of insight.

Contact information

Injection molding is a manufacturing process in which a material, usually plastic, is melted and injected by a machine into a mold. The mold is a cavity that is shaped like the desired part, and the injected material hardens as it cools to take on the shape of the mold. Injection molding is commonly used to produce medical laboratory products such as test tubes, pipette tips, and petri dishes. The process is efficient and can produce large quantities of parts with high precision and consistency.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Eight Cup Magnetic Sleeve Rod Mold Manufacturers and Wholesale Eight Cup Magnetic Sleeve Rod Mold Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

Outdoor Waste Sorting Box Plastic Injection Mould

-

Environmentally Friendly Plastic Cup Injection Mould

-

Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Tail Light Mould

-

Motorcycle Taillight Lampshade Injection Mold

-

Motorcycle Turn Signal Lamp Plastic Injection Mould

-

Plastic Injection Car Headlamp Mould

-

Car Bumper Bracket Plastic Injection Mould

-

Car Front Bumper Injection Mould

-

Auto Headlight Plastic Injection Mold

-

Auto Precision Sensor Injection Mold

-

Medical Laboratory Plastic Petri Dish Injection Mold

English

English 中文简体

中文简体