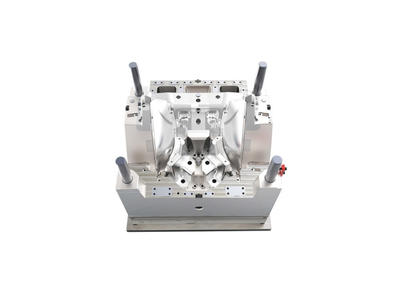

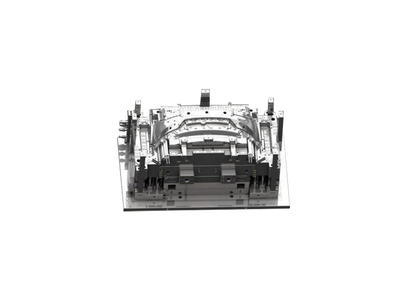

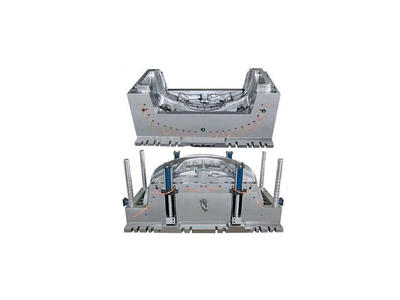

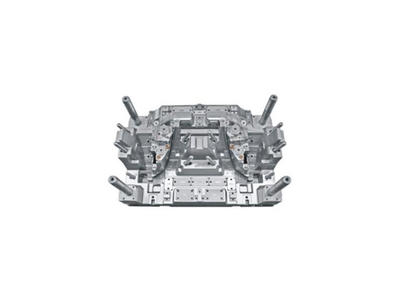

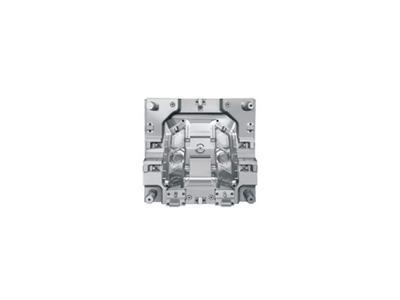

Medical Laboratory Disposable Micropipette Tip Mould

Details

Production Process

(For more details, please feel free to contact us.)

Injection molding is a manufacturing process in which a material, usually plastic, is melted and injected by a machine into a mold. The mold is a cavity that is shaped like the desired part, and the injected material hardens as it cools to take on the shape of the mold. Injection molding is commonly used to produce medical laboratory products such as test tubes, pipette tips, and petri dishes. The process is efficient and can produce large quantities of parts with high precision and consistency.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Disposable Micropipette Tip Mould Manufacturers and Wholesale Medical Laboratory Disposable Micropipette Tip Mould Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

OEM Household plastic chair mould making dining Office plastic armless chair molding

-

Motorcycle Headlight Decorative Frame Injection Mold

-

ABS plastic Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Turn Signal Lamp Plastic Injection Mould

-

Plastic Injection Car Headlamp Mould

-

Car Bumper Bracket Plastic Injection Mould

-

Car Front Bumper Injection Mould

-

Auto Headlamp Housing Injection Mold

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Auto Headlight Plastic Injection Mold

-

Medical Laboratory Plastic Petri Dish Injection Mold

-

Medical Laboratory 96 Well Round Hole Deep Well Plate Plastic Injection Mold

English

English 中文简体

中文简体