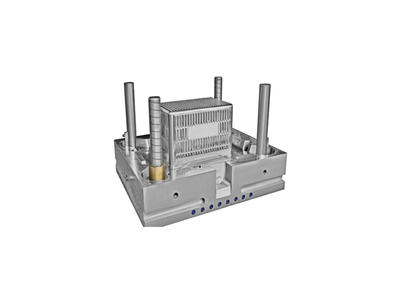

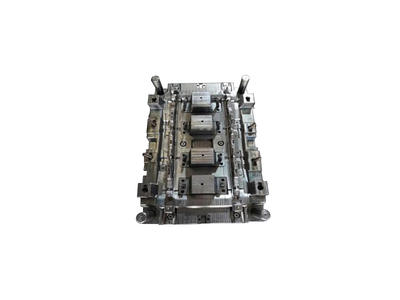

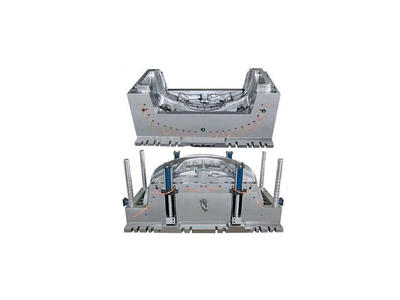

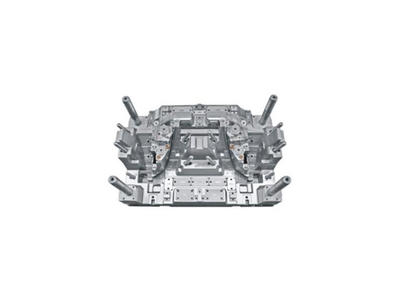

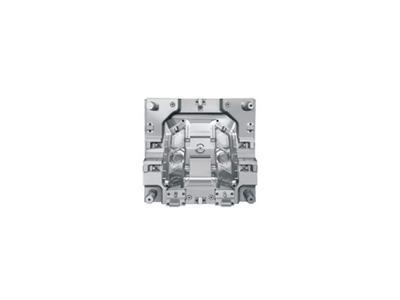

Plastic Injection Car Headlamp Mould

Product Name: Plastic Injection Car Headlamp Mould

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Shipping Conditions: FOB, EXW

Runner: cold runner or hot runner.

Design software: CAD, CAXA, UG, PROE, etc.

Mold life: at least 500,000 times.

Color: according to customer requirements.

Mold material: P20718H, 738, S1362343, etc.

Size: As shown or customized size.

Cavities: single or multiple or up to you.

Product material: ABS, PP, PE, PC, PA, PMMA, POM, TPU, etc.

Design requirements: vertical or horizontal mold design.

Payment method: Sight Letter of Credit, telegraphic transfer (L/C at sight,T/T)

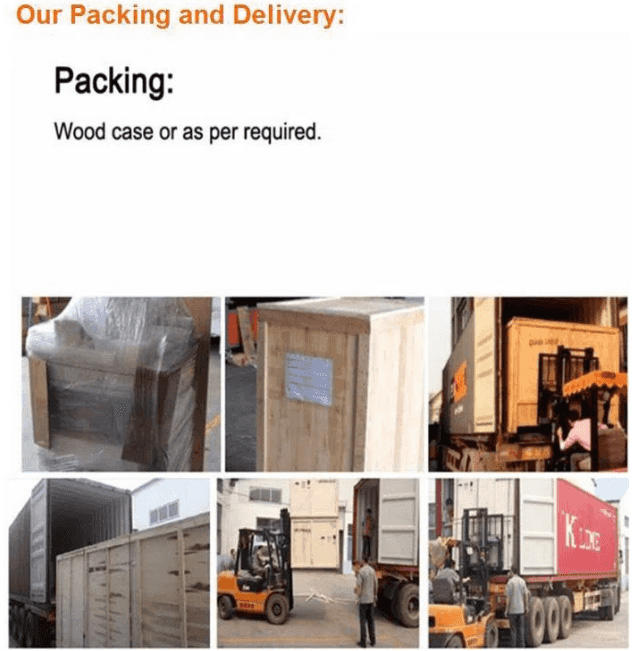

Packing: Standard export wooden box packing, or according to your requirements.

Details

Detail information of mould steel:

| Mould material | mould hardness | mould life |

| P20 | HRC 29-33 | 100000 shots |

| H13 | HRC>4 | 1000000 shots |

| 718 | HRC>4 | 300000 shots |

| S136 | HRC 48-52 | 500000 shots |

| 2344 | HRC >48 | 800000 shots |

Supply capacity

3: How to control the quality?

Our factory has more than 20 years of manufacturing experience. We carry out 100% testing before delivery to ensure that the quality is intact before shipping.

4: What if I receive bad quality goods?

If there is a quality problem to cause you trouble, please communicate with us in time, we will extend the after-sales time, try our best to assist to completely solve.

Injection molding is a manufacturing process in which a material, usually a type of plastic, is melted and injected by a machine into a mold. The mold is then cooled, and the solidified part is removed from the mold. Injection molding is used to produce a wide variety of parts, including car parts. Some examples of car parts that may be produced using injection molding include dashboard components, door panels, and air intake manifolds. The process is efficient and can produce parts with a high level of accuracy and repeatability.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Plastic Injection Car Headlamp Mould Manufacturers and Wholesale Plastic Injection Car Headlamp Mould Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

Revolving Logistics Storage Box Injection Mould

-

Motorcycle Tail Light Mould

-

ABS plastic Motorcycle Headlight Decorative Frame Injection Mold

-

Motorcycle Taillight Lampshade Injection Mold

-

Motorcycle Turn Signal Lamp Plastic Injection Mould

-

Plastic Injection Car Headlamp Mould

-

Automotive Led Front Fog Lamp Parts Plastic Molds

-

Car Front Bumper Injection Mould

-

Auto Headlamp Housing Injection Mold

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Auto Headlight Plastic Injection Mold

-

Eight Cup Magnetic Sleeve Rod Mold

English

English 中文简体

中文简体