In recent years, with the development and versatility of the plastic industry. The application range of plastic products is becoming more and more extensive, such as: household appliances, instrumentation, construction equipment, automobile industry, daily hardware and many other fields, the proportion of plastic products is increasing rapidly. However, with the increasing trend of plasticization of industrial products and daily-use products, the strength and accuracy of plastic products are also constantly improving. Therefore, in order to obtain better strength and accuracy of the mold, it is necessary to carry out two-color Mold injection molding process. So what is the two-color mold injection molding process?

Two-color mold injection molding process:

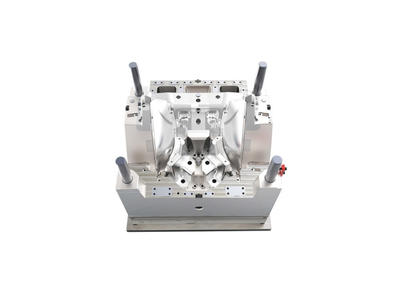

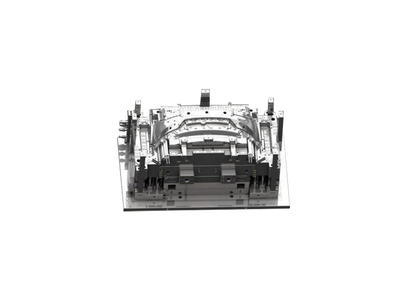

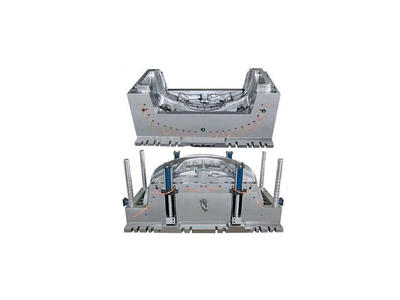

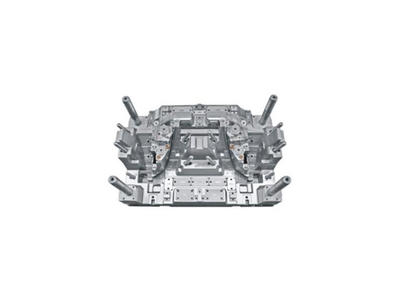

A mold is a tool for producing plastic products. It is generally composed of several groups of parts, and this combination has a molding cavity. During injection molding, the two-color mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and cooled and shaped in the cavity, and then the upper and lower molds are separated, and the product is ejected from the cavity through the ejection system to leave the mold, and the mold is closed again. For the next injection, the entire injection process is cyclic.

Plastic raw materials, toners, nozzle materials, molds, injection molding machines, peripheral equipment, fixtures, sprays, various accessories and packaging materials are required in the injection molding production process. In order to make the production and operation of the injection molding workshop smooth, it is necessary to manage the personnel, materials, equipment, tools, etc. involved in each link and each position, including: raw material room, scrap material room, batching room, production site, post-processing room, etc. Operation and coordination management of processing area, tool room, semi-finished product area, office and other areas.

Because the mold or semi-finished product needs to be rotated, the requirements of mold design and injection molding machine are more precise. In addition, due to the high variability of two-color mold injection molding, to achieve smooth production and meet expectations, all mold design must be considered simultaneously with product design.

The content described above is the two-color mold injection molding process. With the continuous maturity of my country's two-color mold injection molding process, my country is gradually becoming a manufacturing base for global consumer products. In recent years, plastic product manufacturers in South China have undertaken many orders that require two-color mold injection techniques. Mold injection technology should be more sophisticated.

English

English 中文简体

中文简体