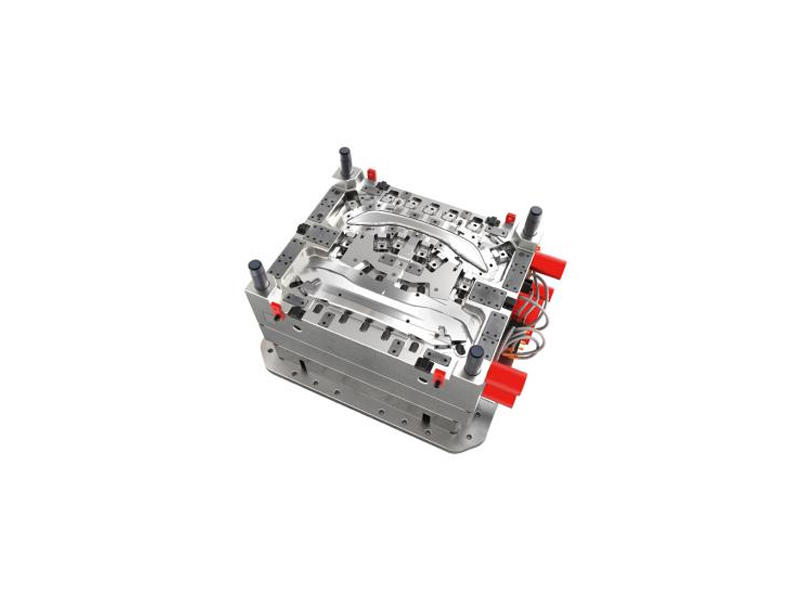

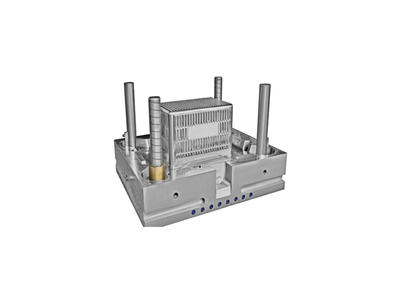

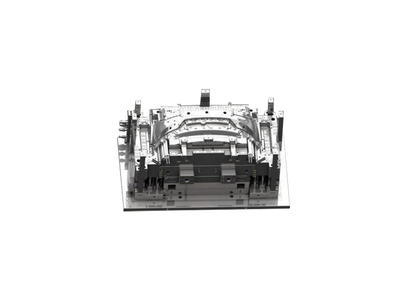

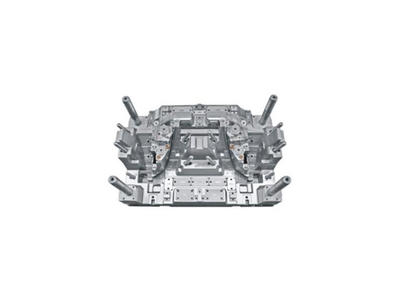

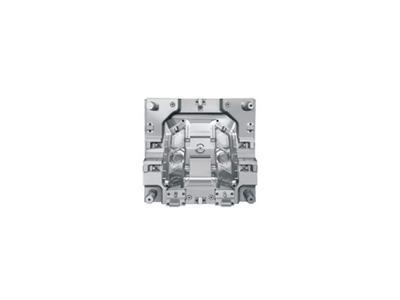

Motorcycle Headlight Lamp Shell Injection Mold

Name: Motorcycle Headlight Lamp Shell Injection Mold

Brand Name: Anye

Place of Origin: Taizhou, Zhejiang, China

Mold type: injection mold, small, medium, large mold

Mould material: S136, P20, 718H, 2738, NAK80, 1.2311, etc.

Number of cavities: 1+1, 1+2+1, 2+2, 4+4, single or multiple

Cycle time: 10-30 seconds

Injection molding machine weight: 90-1000 tons

Die life: 300k-1000k

Shrinkage: According to material

Product material: PE, PP, HDPE, PPR, PVC, PP, PS, PET, ABS, PC, etc.

Injection Type: Hot Runner

Number of drops: cold runner, hot runner, sequential injection

Gate point: edge gate, pin gate, sub gate, fan gate, Bayer

Ejector: round ejector

Slider: outer slider, inner slider, lifter

Surface Finish: High Tech Polished, High Gloss, Textured, VDI 3400

Mold heat treatment: tempering, quenching, nitriding

Main processing equipment: Sodick, Seiki, CNC, high-speed engraving, EDM, wire cutting, drill

Details

T1 (first detection) sample: about 25 days

Payment method: Telegraphic transfer 30% deposit, balance payable before shipment, L/C, Western Union, Huitong, etc.

In the FAQ column, delete the last two paragraphs below "If the project is approved, we require an initial investment of 50% of the mold cost to cover the cost of materials and then start construction."

After the mold is completed, we will produce a batch of sample parts from the mold, which are included in the mold price, and when the parts are approved, the remaining 50% of the mold will be invoiced for a net 30%."

Medical laboratory product injection molding is a process used to manufacture plastic parts and components for use in a medical laboratory setting. In this process, melted plastic material is injected into a mold cavity, where it cools and solidifies into the desired shape. Injection molding is a cost-effective method for mass-producing plastic parts and is often used for producing components such as pipettes, test tubes, and other laboratory supplies. Injection molds can be made to produce parts with very precise dimensions and can be used to create complex shapes and features. The medical laboratory industry relies on injection molding to produce high-quality, accurate, and reliable products that are essential for conducting experiments and analyzing results.

Company Profile

Taizhou Huangyan Anye Industry and Trade Co., Ltd. is professional China Motorcycle Headlight Lamp Shell Injection Mold Manufacturers and Wholesale Motorcycle Headlight Lamp Shell Injection Mold Factory. There is a professional design team, focusing on product quality, daily necessities molds, turnover box molds, SMC mold tray molds, pipe fittings molds, electronic product molds, etc. The company has always focused on product goals, customer-centric and quality-oriented development. He has many years of production experience in mold manufacturing, design and development. The main products are auto parts mold design, development and production. The mold development department, product development design department and mold maintenance department can independently develop and design from molds to finished products.

Contact Us

Related Products

-

Revolving Logistics Storage Box Injection Mould

-

Environmentally Friendly Plastic Cup Injection Mould

-

Motorcycle Headlamp Housing Plastic Injection Mould

-

Motorcycle Turn Signal Lamp Plastic Injection Mould

-

Motorcycle Headlight Lamp Shell Injection Mold

-

Car Bumper Bracket Plastic Injection Mould

-

Auto Headlamp Housing Injection Mold

-

General Motors Interior Plastic Durable Armrest Storage Box Mould

-

Auto Headlight Plastic Injection Mold

-

Medical Laboratory Disposable Micropipette Tip Mould

-

Medical Laboratory Plastic Petri Dish Injection Mold

-

Eight Cup Magnetic Sleeve Rod Mold

English

English 中文简体

中文简体